Leading the way in sustainable two-stroke propulsion

MAN B&W two-stroke engines offer unrivaled fuel flexibility and thus future-proof propulsion. Our two-stroke engines are already now capable to operate on a broad variety of alternative fuels – from methanol, to methane and ammonia.

By placing your trust in a reliable partner, you can benefit from reliable and proven technology – today and in the future.

Let’s navigate the future of shipping together.

High power combined with high efficiency:

Discover our portfolio of proven MAN B&W two-stroke engines

MAN B&W ME-C

Our ME-C engines with

electronic controls serve up a host of advantages. You can look forward to

superior performance parameters, compactness, fully integrated electronic control

as well as the necessary fuel injection pressure and rate shaping at any load.

Plus the ME-C engine can be retrofitted for alternative fuels such as methanol,

LPG, LNG or ethane as well as ammonia from 2025.

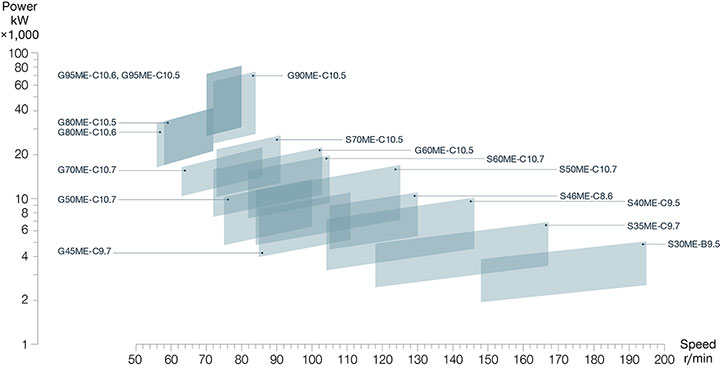

- Engine speed: rpm to 56 – 167

- Output: 4,350 – 82,440 kW at L1

MAN B&W ME-GI

The ME-GI engine impresses with extremely low methane slip emissions and very high fuel efficiency. It is the most environmentally friendly LNG-fuelled engine on the market. By the optional use of fuel oil or LNG/bio-methane/SNG, it represents a highly efficient, flexible, propulsion-plant solution.

- Engine speed: rpm to 56 – 167

- Output: 4,350 – 82,440 kW at L1

MAN B&W ME-GIE

The technology of the ME-GIE is based on our successful ME-GI engine. This engine can be operated with ethane as well as fuel oil – which makes it the standard choice for ethane carriers. This engine offers very competitive fuel oil and gas consumption, plus operational stability and efficiency due to the diesel principle.

- Engine speed: 62 – 127 rpm

- Output: 8,600 – 29,120 kW at L1

MAN B&W ME-GA

The ME-GA engine is the latest addition to our dual fuel portfolio. Gas is admitted during the compression stroke, which allows for a lower supply pressure compared to other dual fuel engines. This is advantageous for LNG carriers with large amounts of boil-off gas. The ME-GA engine comes with our proven EGR design as standard for reduced methane slip emission, as well as improved fuel efficiency in both gas and fuel oil mode.

- Engine speed: rpm to 66 – 78

- Output: 14,150 – 16,980 kW at L1

MAN B&W ME-LGIM

Our ME-LGIM is a dual-fuel engine characterized by its high efficiency and capability of operating on methanol. With a proven record of more than 600.000 operating hours on methanol alone, the engine concept is proven and provides a high degree of reliability.

When fuelled by green methanol, our ME-LGIM engine can offer truly carbon-neutral propulsion, while reducing sulphur and particle matter emissions significantly at the same time.

- Engine speed: 58 – 117 rpm

- Output: 6,950 – 82,440 kW at L1

MAN B&W ME-LGIP

Our ME-LGIP is the only two-stroke dual-fuel engine on the market which can be fuelled with LPG. The low operational costs as well as the simple retrofit solution are particularly convincing.

- Engine speed: 62 –105 rpm

- Output: 8,600 – 22,720 kW at L1

Always an optimal choice

The MAN Energy Solutions two-stroke portfolio delivers the highest performance and efficiency across all engine types.

MAN B&W two-stroke engines from the 30 to 95 cm bore sizes have a total power range from 3,200 kW to 82,440 measured at L1. With a vast range of different fuel injection concepts from traditional fuel oils, to gaseous and liquid gasses, MAN ensures that you have your future fuel strategy covered.

All MAN B&W engines follow the same naming convention and seemingly random engine names actually carry a lot of useful information.

Explore our interactive marine propulsion systems

Worldwide service solutions

Dedicated to developing solutions

Are you are wondering what role our two-stroke technologies could play in your future? We are happy to answer your questions.

Useful tools

Continue reading

-

Marine engine programme 2024pdf, 18117 KB

-

The Methanol-fuelled MAN B&W LGIM enginepdf, 9427 KB

-

MAN B&W ME-LGIMpdf, 504 KB

-

Ultimate protection for your cylinder linerspdf, 1049 KB

-

Economiser energy control for increased service steam production.pdf, 3390 KB

-

Power into the future B&W ME-LGIP:pdf, 1511 KB

-

Onsite Recovery_Customized recoverypdf, 573 KB

-

Onsite Recovery Bearing line recoverypdf, 602 KB

-

Onsite Recovery Stud and threadpdf, 597 KB

-

Onsite Recovery Cast ironpdf, 555 KB

-

Onsite Recovery Cylinder coverpdf, 508 KB

-

Onsite Recovery Main journalpdf, 1895 KB

-

Onsite Recovery Crankpinpdf, 561 KB

-

Onsite Recovery Main bearing saddlepdf, 1651 KB

-

MAN B&W ME-GApdf, 2419 KB

-

Efficiency improvements Main engine auxiliary systemspdf, 4409 KB

Related products

-

Four-stroke small-bore engines

With our small-bore engines, you are prepared for whatever lies ahead.

-

-

MAN B&W ME-LGIM

The MAN B&W ME-LGIM is a two-stroke, dual fuel engine that runs on both methanol and conventional fuels.

Related news

World-First ME-GA Engine Demonstration

MAN Energy Solutions has has demonstrated its latest low-speed, dual-fuel engine – an MAN B&W ME-GA type designed for LNG/fuel-oil running – at a ceremony live-streamed from its Copenhagen Research Centre today. The new engine is an Otto-cycle variant of the company’s successful ME-GI engine.

As its pre-mixed combustion results in low NOx emissions, the ME-GA engine is inherently Tier II and Tier III compliant in gas-operation mode. To fully utilise its dual-fuel potential in Tier III areas, the engine is being offered with Exhaust Gas Recirculation (EGR).

Wayne Jones OBE, Chief Sales Officer, MAN Energy Solutions, participated in the event, which was hosted by Bjarne Foldager, Senior Vice President and Head of Two-Stroke Business, and Thomas S. Hansen, Head of Two-Stroke Promotion and Customer Support.

Jones said: “Our development of new technologies is directly influenced by the close relationships we have with our customers. We initiated this ME-GA project in late 2017 when we recognised a strong market desire for a lower-cost alternative to the ME-GI engine, driven primarily by the LNG carrier market. Crucially, this new supplement to our dual-fuel portfolio continues our mission to decarbonise shipping and further the maritime energy transition to sustainable fuels.”

MAN Energy Solutions aims to start testing the first, commercial ME-GA design by the end of this year, with the first engine delivery following in early 2022.

Foldager said: “It’s taken a team of 150 colleagues, and hundreds of tests and operational hours, to get the engine to this important stage. In doing so, we have drawn on the invaluable experience gained from developing our successful ME-GI concept. Similarly, our proprietary EGR system also plays an important role in the ME-GA set-up. Not only does it deliver NOx-compliance, it also helps maintain control of the ignition process and reduces fuel consumption by 3 and 5% in gas and fuel-oil modes, respectively.”

He added: “This is just the latest milestone in the dual-fuel strategy we have followed over the past decade, and further confirms our leadership in this critical marine segment. Our dual-fuel engines continue to act as standard bearers for environmentally friendly, reliable propulsion-technology with their seamless switching between fuels. Ultimately, we expect the ME-GA to become standard among LNG carriers.”

MAN Energy Solutions reports that its portfolio of two-stroke, dual-fuel engines has accumulated over 1.6 million operating hours from the 155 engines (6.3 GW) currently in service – all running on clean fuels such as LNG, LPG, ethane and methanol. With fuel prices and availability currently in flux, MAN Energy Solutions expects the option of retrofitting to dual-fuel engines to increasingly become a necessity.

About ME-GA

The high-efficiency MAN B&W ME-GA engine delivers a low CAPEX solution aimed at certain vessel types and applications, such as LNG carriers, that are able to use ‘boil-off’ gas as a source of fuel. It will also be of appeal to smaller vessels where low capital outlay is a priority.

Based on the well-proven MAN B&W dual-fuel design with minimal installation requirements, the MAN B&W ME-GA uses an efficient ignition concept and unique gas-admission system that delivers safe and reliable operation.

The ME-GA furthermore features minimal operational costs, simple supply and purging concepts, and low maintenance costs for its fuel-gas supply system. With Tier III compliance in gas mode, the engine meets all current and upcoming NOx emission regulations with the addition of EGR.

About EGR

Already in November 2020, MAN Energy Solutions announced that it would offer its proprietary EGR (Exhaust Gas Recirculation) system as an emissions solution for the ME-GA. EGR is a NOx-emissions-reduction technique that ensures IMO Tier III-compliance in diesel mode for the ME-GA.

The company reports that EGR will enable the ME-GA to reduce specific gas consumption by ~3%, and specific fuel-oil consumption by 5%. It will also significantly reduce methane slip by 30 to 50%, and improve the stability of the Otto-cycle combustion process. EGR will enable the ME-GA to meet Tier III requirements in both fuel oil and gas modes without additional aftertreatment.

The ME-GA EGR solution is a high-pressure system, which can be integrated into existing engine-room designs, and the EGR unit itself does not change the engine footprint. Its design-similarity to that of ME-C engines’ EGR systems will lower its price point, since the supply chain and components are already matured.

The volume requirements of the ME-GA EGR system are also significantly lower with, for example, less pipework required than for low-pressure EGR solutions.

The Maritime Energy Transition

MAN Energy Solutions believes that it is time for what it terms a ‘Maritime Energy Transition’ to find clean, decarbonised solutions for seaborne trade and transportation. Essentially, it is the company’s call to action to reduce emissions and establish natural gases as the fuels of choice in global shipping. It strongly promotes a global ‘turn to gas’, driven by the IMO, and a common approach by the shipping industry and politics to invest in infrastructure development and retrofits.

Documents

-

20210318_MAN_ES_PR ME-GA Unveiling_EN

-

20210318_MAN_ES_PR ME-GA Unveiling_DE

Contact

Nils Søholt

Trade Press Marine

Group Communications & MarktingMAN Energy SolutionsTeglholmsgade 412450 Copenhagen SVDenmark

nils.soeholt@man-es.com t +45 33 85 26 69Available languages

- DE ·

- EN