MAN PrimeServ: fueling the alternatives

Three factors are driving the interest in alternative fuels for shipping and power generation: decarbonization, availability, and economics. As service experts, at MAN PrimeServ we evualate your options, help you plan, and execute the necessary changes. We specialize in retrofitting engines to run on alternative fuels.

Our decarbonization strategy builds on a range of technologies. These include the production of green hydrogen and synthetic fuels, expanding our portfolio of engines that run on alternative fuels, and providing retrofit and upgrade solutions to decarbonize existing ship engines and power generation plants. Retrofitting is one of the most direct ways to help our clients achieve their 'net zero' targets.

Expertise all along the value chain

Energy-intensive industries face higher standards for emission levels and complex investment decisions. Our MAN PrimeServ experts in alternative fuels and sustainability solutions can help you evaluate your options with a multidimensional approach including scalability, return on investment, and the benefits to your operation. Our knowledge extends along the whole alternative fuels value chain, thanks to our experience in R&D, our operation of power-to-X plants, and a multitude of engine retrofit and upgrade solutions.

The value of multiple options

Forecasting the future is a tricky business. Fuel prices showed massive fluctuations in the period 2019-2022. Predicting the supply, demand, or prevalence of one future fuel over another is currently impossible. By continuously researching and developing state-of-the-art retrofit solutions, we can now offer multiple options for full fuel flexibility, engine-integrated emission reduction technologies and digital & data-supported operation.

Explore your fuel options

Know the alternatives

No matter what kind of vessel or plant you operate, our proven, fuel-flexible engines and propulsion systems safeguard your fuel strategy and allow you to take advantage of favorable market conditions. We can support you with a large and growing portfolio of retrofit solutions, upgrades, and services, designed to optimize returns from your existing investments.

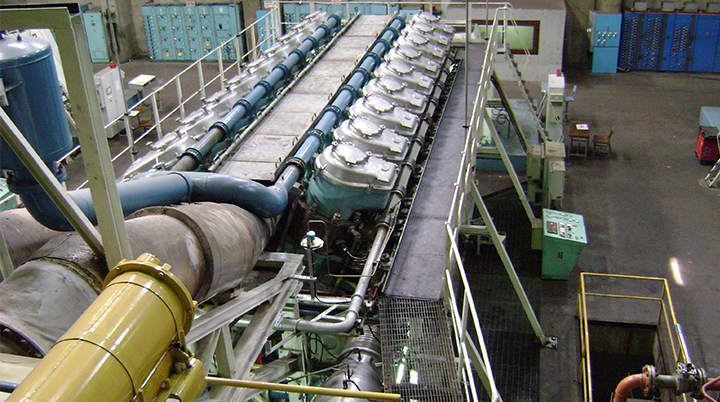

Fuel flexibility in single fuel engines

A single fuel engine can run on different types of liquid fuel. The principal options are heavy fuel oil (HFO), marine diesel oil (MDO), biofuels, and low-sulphur fuels. Each of our two-stroke and four-stroke engines offers different options. For example, the two-stroke MAN B&W ME-C is design to run on biofuels as well as conventional diesel.

Learn more about Type Approval Test for MAN L23/30H Mk3 Engine

Fuel switching with dual fuel engines

MAN dual fuel engines are especially flexible in their use of both liquid and gaseous fuels. They allow you to change fuel when it is most convenient to you, which might depend on prices or regulations. They can even change fuel during operation without altering engine performance. Some single fuel engines can be converted to dual fuel. Depending on your circumstances, this might also require changes to your supply infrastructure. Our MAN PrimeServ fuel experts can advise you on your options.

The MAN 35/44G TS, MAN 51/60G, and MAN 51/60G TS gas engines, which are frequently used in power plants, can be operated with a hydrogen volume share of up to 25 % in the gas mixture.

MAN 35/44DF CD GenSet is future fuel readiness. This includes being ready for dual-fuel methanol operation will arrive mid-2024 on the market. This modern and powerful dual-fuel engine is especially aimed at lng carrier and containership applications and impressively reduces methane-slip.

Learn more about dual fuel engines for marine

Engine conversion: adapt and evolve

Retrofit are a keystone of our company’s approach to decarbonization. Our technicians know the MAN engines perfectly and are experienced in conversions. We can already convert conventional fuel engines into dual fuel systems that can also be run on biofuels, synthetic diesel or gas. At short notice, we could convert engines into DF methanol or ammonia engines. Retrofitting an engine extends its operational life substantially and reduced CO² emissions.

Examples of conversions and adaptation include the ElbBLUE container ship, which MAN enabled to run

on climate-neutral synthetic natural gas (SNG) and BW Malacca ship received ME-LGIP engine conversion:

the ship's MAN B&W 6G60ME-C9.2 type engine was retroffited to an MAN B&W 6G60ME-C9.5-LGIP dual-fuel type capable of operating on fuel oil and LPG.

Dual fuel conversions for ships

More about the first container ship to run on climate-neutral SNG

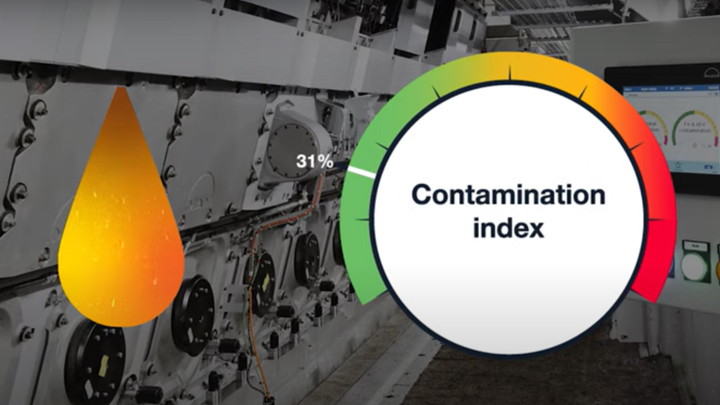

Engine monitoring for successful fuel change

Changing fuels can have consequences on your engine. MAN PrimeServ offers you the expertise and tools to track and detect critical effects in components, engines, or plants.

- Lube oil condition is a key indicator: the MAN Multi Fluid Monitor provides an early warning system to discover any secondary effects.

- PrimeServ Assist is a continuous monitoring and advisory service that provides real-time data of overall engine performance and individual engine component condition.

- The MAN EcoLoad tool provides optimal operation advice for complete plants with multiple engines – saving you money and protecting the environment.

Fuel for thought. Check the alternatives

Alternative fuels are important because they allow us to decarbonize sectors that are hard to electrify, such as shipping. This is especially true of so-called e-fuels, which are derived from renewable energy sources. MAN Energy Solutions not only provides engines that run on alternative fuels but is active in the production of e-fuels. Our Power-to-X processes convert renewable energy sources into hydrogen, SNG, methanol, and ammonia.

Talk to our experts

Explore more topics

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.