Reducing the release of methane into the air is crucial for cleaner shipping with LNG. An expert tells us how it can be done

With low-carbon liquefied natural gas (LNG) garnering widespread acceptance as a transitional fuel on the path to zero-carbon shipping, methane slip has become a mainstream conversation. Methane, which typically makes up 85–95 percent of LNG, has a global warming potential 28 times stronger than carbon dioxide when calculated over 100 years, making it a potent greenhouse gas. Across the whole supply chain, a small but significant amount of unburnt methane ends up in the atmosphere – more commonly known as methane slip. Can it be prevented? We spoke to Gunnar Stiesch, Head of Engineering Engines at MAN Energy Solutions, about the policies that can help reduce methane slip from engines and the promise of a new aftertreatment solution to be piloted on board a vessel in 2022.

By Oliver Sachgau

“We need to address the issue of methane slip quickly,” says Gunnar Stiesch, Head of Engineering Engines at MAN Energy Solutions.

When we talk about methane slip, the stress is always placed on prevention. Why is this so crucial? Is there no way to recapture methane like the direct air capture of carbon, to put the proverbial genie back in the bottle?

Gunnar Stiesch: Once the methane is out, the quantities and concentrations in the atmosphere are so low that it's close to impossible to get a hold of it again. So no, unlike carbon dioxide, recapturing methane isn’t feasible.

We also have to keep in mind that carbon dioxide stays in the atmosphere for several thousand years, while methane has an average atmospheric lifetime of only around 12 years. Then it naturally decomposes into water vapor and carbon dioxide. This means that direct prevention offers far more opportunities to control methane in the atmosphere – which is why we need to address the issue of methane slip quickly. Using technical solutions to reduce methane slip can have a real impact on climate change and our environment.

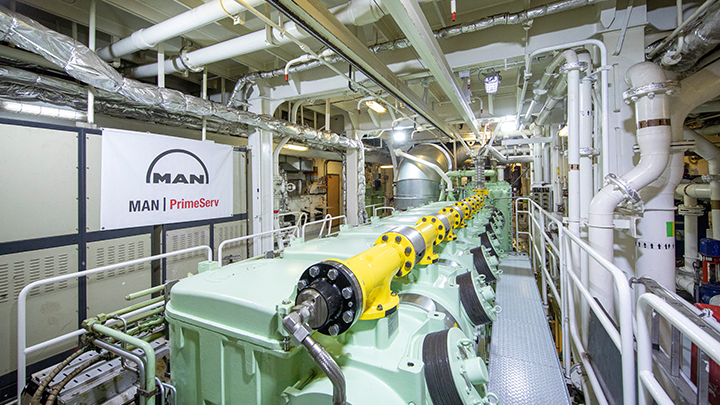

To date, MAN Energy Solutions has managed to reduce methane slip in their ME-GI two-stroke dual-fuel engines to a range between 0.2–0.3 grams per kilowatt hour. How much lower can that number go?

Well, we can get that number even lower, sure, but we have to remember that when we look at the entire greenhouse gas impact of these engines it’s already close to negligible. Upgrades will definitely have lower values in the future, but our main focus is addressing those engines that still have a higher methane slip. For example, Otto-cycle dual-fuel engines have an inherently higher methane slip than our Diesel-cycle ME-GI. To minimize this as much as possible, we’re using our well-proven exhaust gas recirculation (EGR) technology on our Otto-cycle ME-GA engines.

Using technical solutions to reduce methane slip can have a real impact on climate change and our environment.

Let’s talk about four-stroke engines. Two of the options MAN Energy Solutions is pursuing with these engines are direct gas injection and aftertreatment with an oxidation catalyst. How’s the assessment going so far?

Direct gas injection is technically feasible: Four-stroke engines can run with high pressure gas injection on the Diesel combustion scheme that two-stroke ME-GI engines are already running today. And the resulting methane slip would be in a similar range, lower than for Otto cycle gas engines. But under the current framework and boundary conditions, it’s not a cost-competitive solution for four-stroke engines. At the moment, it makes more sense to focus on all the things that can be done to improve the Otto cycle technology.

Can you explain the Otto cycle technology process, and why improving it is the better option?

On a four-stroke engine, Otto cycle means that we’re mixing gas and air before the charge enters the cylinder. Then we compress this more-or-less homogenous mixture in the combustion chamber and ignite it with a small pilot flame. So we have premixed combustion, and there are ways to improve this process.

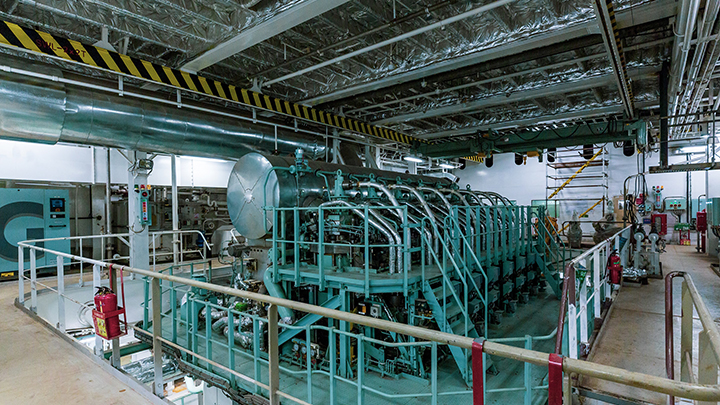

Managing methane slip for two-stroke engines: even now MAN ME-GI dual-fuel engines guarantee negligible methane-slip levels in a range from 0.2–0.3 g/kWh over the engine’s entire load range.

Since the introduction of the MAN 51/60 dual-fuel engine over ten years ago, MAN engineers have already been able to cut methane slip in half for today’s four-stroke dual-fuel engines.

The most straightforward way is to look at the internal engine architecture and reduce the crevice volumes in the combustion chamber – areas where pockets of unburnt methane can’t be reached by the flame. Or we can look at the overlap of inlet and exhaust valves and the timing of gas admission. Thus, in the last ten years we have already been able to halve methane slip from our four-stroke gas engines and we are confident that we can achieve another 20 % by further improving the combustion process.

Furthermore, Otto-cycle gas combustion is characterized by a natural trade-off between methane slip and NOx emissions. For engines equipped with a Selective Catalytic Reduction (SCR) catalyst for NOx abatement, this trade-off can be used to tune the combustion process towards lower methane slip and slightly higher NOx, which can then be easily reduced again by the SCR. This is fully proven technology and available today.

Besides these combustion measures, is there more that you could do?

Aftertreatment with an oxidation catalyst – or “oxicat” – is a promising external measure. We started developing oxicat in 2017, and we’ve made great progress in the laboratory with a 70 percent methane slip reduction. The first pilot installation on board a vessel will start in 2023. And then after the full tests, we expect to see this as a major technological solution for methane slip reduction, widely available roughly around 2025.

It’s important to have ambitious regulations, including greenhouse gas pricing, but they need to be harmonized globally to make sure that we have a level playing field.

You’ve talked in the past about the importance of retrofits for the maritime energy transition. Will these kinds of improvements also be available for existing older engines?

We’re always looking at the possibility of offering retrofits for existing engines, especially for the oxidation catalyst. That’s a measure we definitely want to make available for existing engines. In fact, the vessel and engine we’ll be using for next year’s pilot test have been in operation for some time. We’re basically retrofitting this pilot installation, and something similar will be possible for other engines as well in the future.

All of these measures exist in a larger political and social context. And earlier you even mentioned that framework and boundary conditions can be an obstacle to making solutions economically viable. What sort of framework do we need?

If we look at the most recent COP26 Climate Summit, you’ll remember that more than 100 countries agreed to cut methane emissions by 30 percent by 2030. Using this target as a basis, we now have to create more specific regulations that will help us get there, and the industry has to implement the measures.

Shipping is an international industry, and there's worldwide competition between all countries and all regions. So it’s important to have ambitious regulations, including greenhouse gas pricing, but they need to be harmonized globally to make sure that we have a level playing field. From our perspective, it’s fine that the European Commission is taking the first steps with the Fit for 55 proposal to reduce greenhouse gas emissions by 55 percent by 2030, but the International Maritime Organization needs to follow suit.

Typically, 85 to 95 of natural gas is methane, a greenhouse gas more potent than CO2, and across the whole supply chain, a small, but significant amount of unburnt methane can enter the atmosphere if countermeasures aren’t taken.

Managing methane slip

About the author

Explore more topics

-

Propeller hubs and blades

At MAN Energy Solutions Propeller Maintenance Concept covers all your key needs, including inspection, 3D measurement, reshaping or replacing blades, and overhaul of hub windows.

-

Reconditioning exchange

At the MAN Service Center Denmark we have large stocks of reconditioned parts for exchange and we refurbish parts with our precise manufacturer’s knowledge of measurements and materials.

-

Project management

At the PrimeServ Service Center Denmark you get a personal technical project manager to support you with your service needs from the planning to project completion and beyond.

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.