One solution for all your engines, regardless of OEM

MAN Multi Fluid Monitor (MFM) is the word's only solution for continuous lube oil monitoring for your engines. Trusted by hundreds of vessels and power plant operators, it is an invaluable component to maximize engine availability and support your maintenance, digitalization, and decarbonization strategies.

Simple to install and cyber secure, MFM helps you optimize engine performance, regardless of brand, by alerting you of any lube oil anomalies before they become a problem. This is particularly important during high-risk cold starts or when changing to alternative fuels, which can have unpredictable consequences.

MFM is available for all types of 4-stroke engines - MAN and other brands, including engines auxiliaries.

Watch recording for our Multi Fluid Monitor ExpertTalk

Watch recording, 30-minute ExpertTalk on Multibrand Lube Oil Condition Monitoring with Live Demo. Our experts will walk you through how Multi Fluid Monitor works, including a live demonstration.

You can learn more by reading our latest article, Real-time insights: the success of Multi Fluid Monitor, which goes into detail about benefits and who it's for.

Watch how MFM works

- Proven technology with large globally installed base

- Optimizes engine availability while minimizing OPEX and downtime

- Smarter maintenance through digitalization

- Lower maintenance costs

- Supports your decarbonization journey

- Safeguards your engines following transitions to alternative fuels

- Available for any four-stroke engines application, regardless of OEM

Safeguard your digitalization journey

MFM is a flexible, condition-based tool that's part of MAN Asset+, our range of engineering and software solutions designed to improve the performance of your engines and systems, comply with regulations, and support your data-driven digitalization, energy transition, and decarbonization strategies.

MFM is also fully secure, having been certified in accordance with Bureau Veritas Rules for the Classification of Steel Ships and Naval Ships. IACS UR E27 Rev.1 Sep 2023 Cyber resilience of on-board systems and equipment, as well as all other relevant classifications. This means you can rest assured that your system can never be compromised.

caused by lube oil

be detected in lube oil

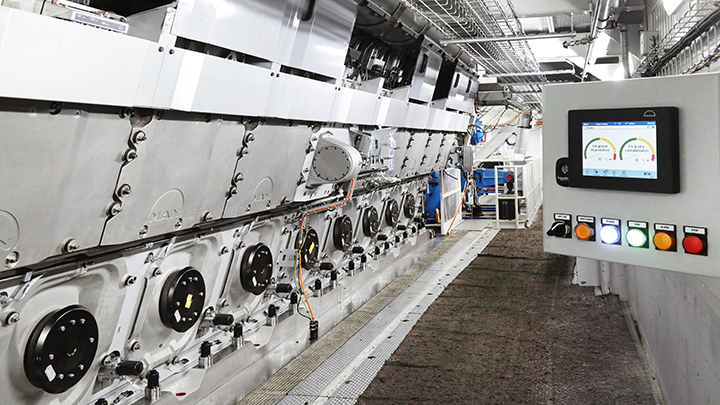

Multi Fluid Monitor in action

Maintenance

Engine type: S.E.M.T. Pielstick PC 2-5

Intervention type: maintenance

Detection: water

Reference 1: “Some time ago, during the maintenance work of a PC2-5, MFM started an alarm: thanks to it we detected that water was falling into the lube oil sump because of a leakage in way of an exhaust valve seat. If we had not known about it, the consequences would have been very serious for the engine and also costly because we would have had to change all the engine lube oil. Since then, I use MFM for all my projects: it is a real advantage to guarantee the quality of our work and point it out to our customers.”Frédéric Albessart, Field Service Engineer, MAN PrimeServ

Reference 2: “We took the opportunity of maintenance works on 16PC2-5 emergency engines to install a Multi Fluid Monitor system. We had two objectives in mind: prevent possible damage occurrences and show to our customer how useful this tool is. The facts proves very quickly how right we were: as soon as it was started MFM detected at the end of the running-in phase an increase of the water contents in the lube oil. The cost of this incident was very low compared to the serious damage we then prevented. Proposal for a Multi Fluid Monitor will be made for the preparation of the second maintenance.” Emma Lechat, Project Manager, MAN PrimeServ

Major overhaul

Engine type: MAN 48/60B

Intervention type: major overhaul

Detection: water

Reference: “During an overhaul, our 48/60B engine being in running-in phase for about 5 hours and as all the operating parameters were good, MFM detected a sudden increase of the water content in the lube oil. We stopped the engine immediately to carry out an internal inspection – a cylinder head was leaking. Without MFM, the water ingress would have been detected too late to prevent the renewal of all the engine lube oil (approx. 20 m3).” Jean-Saül Séry, Field Service Engineer, MAN PrimeServ

Commissioning

Engine type: MAN 32/44 CR

Intervention type: commissioning

Detection: water

Reference: “After some damage occurred – engine flooded at the end of the commissioning phase – I used MFM to restart the engine after draining, flushing and changing the lube oil. This proved that our work had been efficient, i.e. a real saving in terms of time and troubleshooting! The customer, who had received the Multi Fluid Monitor just before the damage occurred, was reassured about his choice, sped up its fixed installation and decided to equip each of his four 32/44 CR (GenSet) engines as well in order to monitor them for correct functioning in the long term.” Dylan Lefeuvre, Field Service Engineer, MAN PrimeServ

Testbed

Engine type: MAN 51/60G

Intervention type: testbed

Detection: ferrous particles

Reference: “At the test bench, during the tests of a 51/60G new engine, the MFM started an alarm: detection of ferrous particles. It was decided to inspect the cylinders: the boroscopic inspection of the first cylinder liner detected severe scuffing. Fortunately, thanks to this early detection, only one liner was damaged. Without this detection the tests would not have stopped; resulting in possible seizing of this cylinder, and maybe a crankcase explosion. The tests were resumed with different liner/piston ring/piston configurations to find out the cause, always under Multi Fluid Monitor monitoring, which has now become systematic” Mickael Limousin, Test Engineer, MAN PrimeServ

Download the white paper

How lube oil

condition monitoring enables

smarter maintenance

Contact our experts

Continue reading

-

MAN Multi Fluid Monitor for lube oil (EN)pdf, 9546 KB