Leading the way in sustainable two-stroke propulsion

MAN B&W two-stroke engines offer unrivaled fuel flexibility and thus future-proof propulsion. Our two-stroke engines are already now capable to operate on a broad variety of alternative fuels – from methanol, to methane and ammonia.

By placing your trust in a reliable partner, you can benefit from reliable and proven technology – today and in the future.

Let’s navigate the future of shipping together.

High power combined with high efficiency:

Discover our portfolio of proven MAN B&W two-stroke engines

MAN B&W ME-C

Our ME-C engines with

electronic controls serve up a host of advantages. You can look forward to

superior performance parameters, compactness, fully integrated electronic control

as well as the necessary fuel injection pressure and rate shaping at any load.

Plus the ME-C engine can be retrofitted for alternative fuels such as methanol,

LPG, LNG or ethane as well as ammonia from 2025.

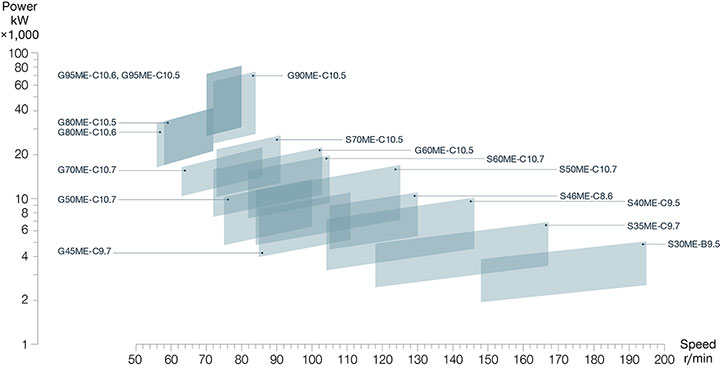

- Engine speed: rpm to 56 – 167

- Output: 4,350 – 82,440 kW at L1

MAN B&W ME-GI

The ME-GI engine impresses with extremely low methane slip emissions and very high fuel efficiency. It is the most environmentally friendly LNG-fuelled engine on the market. By the optional use of fuel oil or LNG/bio-methane/SNG, it represents a highly efficient, flexible, propulsion-plant solution.

- Engine speed: rpm to 56 – 167

- Output: 4,350 – 82,440 kW at L1

MAN B&W ME-GIE

The technology of the ME-GIE is based on our successful ME-GI engine. This engine can be operated with ethane as well as fuel oil – which makes it the standard choice for ethane carriers. This engine offers very competitive fuel oil and gas consumption, plus operational stability and efficiency due to the diesel principle.

- Engine speed: 62 – 127 rpm

- Output: 8,600 – 29,120 kW at L1

MAN B&W ME-LGIM

Our ME-LGIM is a dual-fuel engine characterized by its high efficiency and capability of operating on methanol. With a proven record of more than 600.000 operating hours on methanol alone, the engine concept is proven and provides a high degree of reliability.

When fuelled by green methanol, our ME-LGIM engine can offer truly carbon-neutral propulsion, while reducing sulphur and particle matter emissions significantly at the same time.

- Engine speed: 58 – 117 rpm

- Output: 6,950 – 82,440 kW at L1

MAN B&W ME-LGIP

Our ME-LGIP is the only two-stroke dual-fuel engine on the market which can be fuelled with LPG. The low operational costs as well as the simple retrofit solution are particularly convincing.

- Engine speed: 62 –105 rpm

- Output: 8,600 – 22,720 kW at L1

Always an optimal choice

The MAN Energy Solutions two-stroke portfolio delivers the highest performance and efficiency across all engine types.

MAN B&W two-stroke engines from the 30 to 95 cm bore sizes have a total power range from 3,200 kW to 82,440 measured at L1. With a vast range of different fuel injection concepts from traditional fuel oils, to gaseous and liquid gasses, MAN ensures that you have your future fuel strategy covered.

All MAN B&W engines follow the same naming convention and seemingly random engine names actually carry a lot of useful information.

Explore our interactive marine propulsion systems

Worldwide service solutions

Dedicated to developing solutions

Are you are wondering what role our two-stroke technologies could play in your future? We are happy to answer your questions.

Useful tools

Continue reading

-

MAN L27/38DF-Mpdf, 386 KB

-

The Methanol-fuelled MAN B&W LGIM enginepdf, 9427 KB

-

MAN B&W ME-LGIMpdf, 508 KB

-

Economiser energy control for increased service steam production.pdf, 3390 KB

-

Power into the future B&W ME-LGIP:pdf, 1511 KB

-

Efficiency improvements Main engine auxiliary systemspdf, 4409 KB

Related products

-

Four-stroke small-bore engines

With our small-bore engines, you are prepared for whatever lies ahead.

-

-

MAN B&W ME-LGIM

The MAN B&W ME-LGIM is a two-stroke, dual fuel engine that runs on both methanol and conventional fuels.

Related news

World’s First VLCV Methanol Retrofit Represents Blueprint for Future Projects

MAN Energy Solutions has announced the successful retrofit of the main engine of the ‘Maersk Halifax’ to a dual-fuel MAN B&W ME-LGIM unit. MAN PrimeServ, MAN Energy Solutions’ after-sales division, carried out the work, the first such project globally involving a VLCV (Very Large Container Vessel).

The 15,000 teu vessel entered service in 2017 and was originally powered by an MAN B&W 8G95ME-C9.5 prime mover. The retrofit to an 8G95ME-LGIM Mk10.5 engine enables the Maersk Halifax to operate on green methanol, making it possible to reduce its CO2 emissions by 90%.

The retrofit also included an upgrade to the vessel’s engine-control system to MAN Energy Solutions’ latest Triton system. Following the completion of sea-trials, Maersk Halifax has returned to operation and is now servicing A.P. Moller - Maersk’s (Maersk) Trans-Pacific trade.

Leonardo Sonzio, Head of Fleet Management and Technology at Maersk, said: “Since we set the ambitious climate goal of reaching net zero emissions by 2040, we have explored the potential in retrofitting existing vessels with dual-fuel engines. In the coming year, we will take learnings from this first conversion of a large vessel. Retrofits of existing vessels can be an important alternative to newbuilds in our transition from fossil fuels to low-emission fuels.”

The Halifax retrofit is expected to serve as a blueprint for future retrofit projects. Indeed, Maersk has already placed a preorder for MAN PrimeServ to convert an additional 10 vessels from its fleet to methanol operation.

Michael Petersen, Senior Vice President and Head of PrimeServ Denmark, praised the project collaboration with Maersk and Asia Pacific and said: “Retrofits are one of the five growth areas identified in MAN Energy Solutions’ ‘Moving Big Things To Zero’ strategy, enabling shipowners to drastically reduce CO2 emissions without having to commission newbuilds. Retrofitted engines are able to switch between fuels with minimal disruption, flexibility that is crucial for maintaining operational efficiency and reliability. At PrimeServ, we estimate that more than 4,000 existing marine engines have the potential to be converted to operation on green fuels like e-methanol and e-methane.”

Speaking at a recent event at Asia Pacific Dockyard in Zhoushan to mark the project’s conclusion, Sarath Prasannan, Senior Vice President and Head of Region Asia Pacific, said: “This groundbreaking project marks a pivotal moment in the shipping industry's journey towards decarbonisation. We hope that China's policies and infrastructure will continue to foster an environment where shipyards can carry forward this commendable work.”

About Maersk

A.P. Moller - Maersk is an integrated logistics company working to connect and simplify its customers’ supply chains. As a global leader in logistics services, the company operates in more than 130 countries and employs around 100,000 people. Maersk is aiming to reach net zero emissions by 2040 across the entire business with new technologies, new vessels, and alternative fuels.

Documents

-

PR PrimeServ Halifax_EN

Contact

Nils Søholt

Trade Press Marine

Group Communications & MarktingMAN Energy SolutionsTeglholmsgade 412450 Copenhagen SVDenmark

nils.soeholt@man-es.com t +45 33 85 26 69Available languages

- DE ·

- EN

Get notified about press releases

MAN ExpertTalk: Update on MAN B&W ammonia engine development

Having completed more than 12 months of testing on a single cylinder running on ammonia, the full-scale engine testing started at Research Centre Copenhagen in November 2024.

Tune in for the recording of out MAN ExpertTalk to learn more about this major milestone in the development of new two-stroke technology.

You can look forward to hearing more about our progress and learnings, the design of the safety systems for fuel handling as well as ammonia auxiliary systems.

This MAN ExpertTalk is hosted by Christian Ludwig with presentations by subject matter experts Nikolaos Kourtidis and Ian Kumaraswamy.