LNG for the maritime energy transition

Increasing the benefits of LNG for shipping by decreasing methane slip in four-stroke engines

Does the issue of methane slip affect the climate benefits of LNG as an engine fuel for marine applications? MAN Energy Solutions remains convinced that the switch to LNG marks an important first step towards climate-neutral shipping and has prioritized resolving the issue of methane slip accordingly.

Addressing methane slip

When used as a shipping fuel, LNG offers various benefits both for shipowners, operators, and the environment. With its high heating value combined with a low carbon content, LNG makes it possible to significantly reduce greenhouse gas (GHG) emissions, while the absence of sulfur also decreases the particulate matter (PM) and sulfur oxide (SOx) emissions. LNG is therefore considered a viable transitional fuel on the path towards zero-carbon shipping.

For many years now, MAN Energy Solutions has been offering a wide range of reliable and robust dual fuel four-stroke engines that are suitable for many different applications and thus cater to the growing demands of the shipping industry.

But while this trend is clear, methane slip and its global warming potential are highly relevant topics that also need to be taken into account. The term “methane slip” refers to the emission of small but significant quantities of unburnt methane (CH4) into the atmosphere. This is an issue that needs close observation, as methane is a greenhouse gas that is considerably more potent than carbon dioxide (CO2).

Concepts for four-stroke engines

There are three options for MAN four-stroke dual fuel engines: Direct gas injection, improving the combustion process, and aftertreatment using an oxidation catalyst.

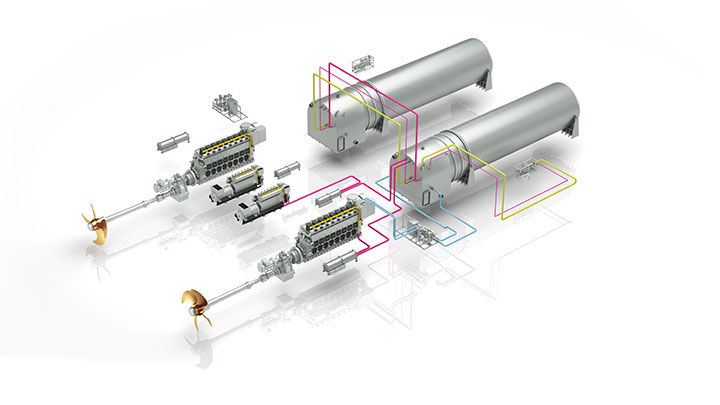

MAN 51/60DF LNG propulsion system. Since the introduction of the MAN 51/60 dual fuel engine over ten years ago, MAN engineers have already been able to halve methane slip in today’s four-stroke dual fuel engines.

Direct gas injection

Direct gas injection is technically feasible: Four-stroke engines can run with high-pressure gas injection according to the Diesel combustion scheme that the proven MAN B&W ME-GI two-stroke engines are already based on today. And the resulting negligible methane slip would be in a similar range, lower than for Otto cycle gas engines. But within the current framework and boundary conditions, it’s not a cost-competitive solution for four-stroke engines. At the moment, it makes more sense to focus on all the things that can be done to improve the Otto cycle technology.

Improving the combustion process:

Engine-internal measures

The Otto cycle on the four-stroke side means that gas and air are mixed before the charge air enters the cylinder. Then this more-or-less homogeneous mixture is compressed in the combustion chamber and ignited with a small pilot flame. This means that premixed combustion takes place, and there are ways to improve this process.

The most straightforward approach is to look at the internal engine architecture and reduce the crevice volumes in the combustion chamber – areas where pockets of unburned methane cannot be reached by the flame. The overlap of inlet and exhaust valves, and the timing of gas admission can also be examined. Thus, over the last ten years MAN Energy Solutions has already been able to halve methane slip in our four-stroke gas engines, and we are confident that we can achieve a further 20% reduction by continuously improving the combustion process.

Furthermore, Otto cycle gas combustion is characterized by an inevitable trade-off between methane slip and NOx emissions. For engines equipped with a selective catalytic reduction (SCR) catalyst for NOx reduction, this trade-off can be used to adapt the combustion process for lower methane slip and slightly higher NOx, which can then be easily reduced again by the SCR. This technology has been tried and tested and is available now.Using technical solutions to reduce methane slip can have a real impact on climate change and our environment.

Exhaust aftertreatment

Aftertreatment with an oxidation catalyst – or “oxicat” – is a very promising external measure. MAN Energy Solutions started developing oxicat in 2017, and since then has made considerable progress in the laboratory with a 70% reduction in methane slip.

The first pilot installation onboard a vessel will start in 2022. Then, after the full tests, it is expected to become a major technological solution for methane slip reduction, and is scheduled to be widely available around 2024.

Retrofit options

With a large number of four-stroke dual fuel engines in operation, there is also the possibility of offering retrofits for existing engines, especially for the oxidation catalyst. This is a measure that should be made available for existing engines. In fact, the vessel and engine that will be used for next year’s pilot test have been in operation for some time. This promising case will therefore be a retrofit. Based on this, a similar solution will be possible for other engines as well in the future.

Read more:

Managing Methane Slip

LNG

LNG stands for liquefied natural gas, natural gas transformed into a liquid state through a cooling process. In its liquid form, natural gas has a significantly smaller volume for export, shipping, and storage. It is a low-emission, clean-burning fossil fuel that can be used for marine propulsion and transportation and regasified after delivery to a terminal.

Main advantages:

- Produces significantly lower SOx, CO2, NOx and particulate matter emissions compared to fuel oils

- LNG is considered to be an excellent bridging fuel during the ongoing energy transition

Focus areas:

- Availability of LNG as bunker fuel is increasing quickly

- Managing methane slip

Methane slip

Watch the video and find out, what our expert Dr. Gunnar Stiesch, is saying about methane, methane slip and why it is so important to address in the marine business.

Methane slip on the two-stroke side

Watch our two-stroke senior specialist Niels Kjemtrup explaining the differences between Otto and Diesel cycle with regards to methane slip.

In this session, our expert Niels Kjemtrup is explaining how methane slip can be measured on the two-stroke side.

This session explains why it is so important to measure the methane slip in the entire load range

Watch Niels Kjemtrup’s statement and find out why the MAN B&W ME-GI two-stroke engine is the perfect fit if negligible methane slip is your focus area.

Solutions / technologies by MAN Energy Solutions:

Two-stroke:

|

|

| Four-stroke: |

|

| MAN PrimeServ: |

|

| Cryogenic equipment |

|

Continue reading

-

MAN B&W ME-GIpdf, 465 KB

-

MAN L35/44DF CDpdf, 478 KB

-

Service for LNG FGSSpdf, 9826 KB

-

EcoOptimizer for CPP systemspdf, 416 KB

-

MAN V49/60DFpdf, 967 KB

-

MAN L49/60DFpdf, 6253 KB

-

Controllable Pitch propeller optimizationpdf, 386 KB

-

MAN Alpha CP propellerspdf, 623 KB

-

LNG Shippingpdf, 38088 KB

-

MAN EcoLoad advisory toolpdf, 1929 KB

-

Four- stroke marine systemspdf, 10891 KB

-

MAN Hybrid EcoAuxpdf, 2090 KB

-

LNGC-optimised designs of ME-GI engines and fuel gas supply systemspdf, 3256 KB

-

ME-GI/GIE pump vaporiser unit for LNG and ethanepdf, 3716 KB

-

LNG gas supply and bunker systemspdf, 767 KB

Other future fuels

Reducing shipping emissions

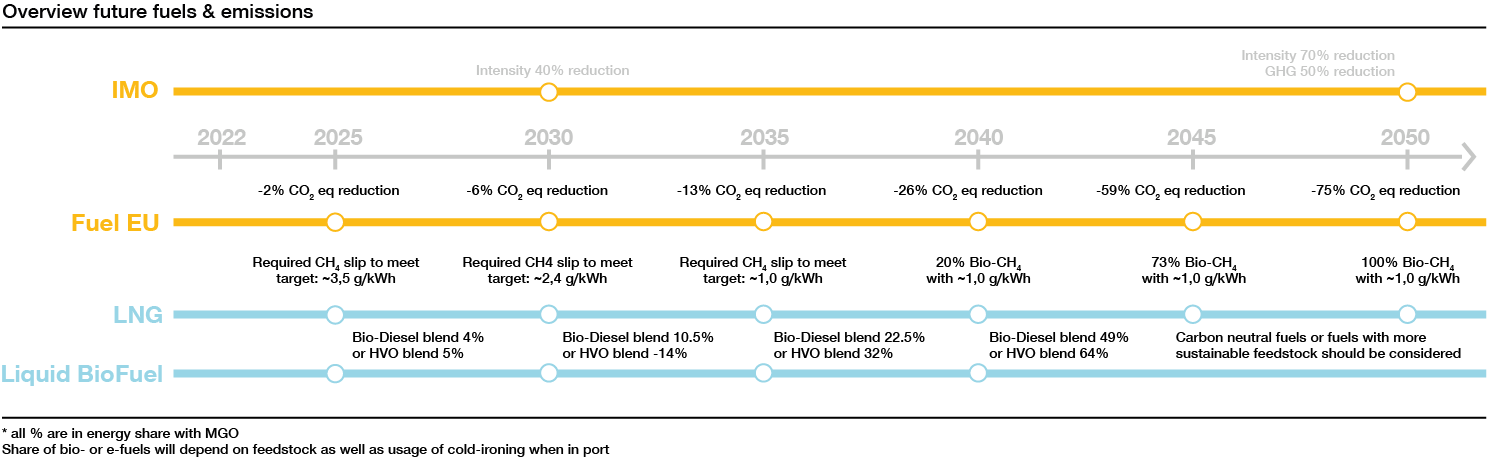

IMO, Fit for 55, EEXI, CII... reducing emissions and becoming more efficient is a mayor issue for the shipping industry in the near future. Register for the recording of our latest four-stroke ExpertTalk to learn more about our portfolio of LNG and dual fuel solutions. The topic will be presented to you by Alexander Feindt, Global Business Development Manager, and Maximilian Bartholy, Head of Product Management Solutions & Engines, PMS.

Methane-fuelled MAN B&W ME-GI two-stroke engine

The MAN B&W ME-GI has been in service for more than a decade already, and with a continuous focus on optimizing the engine design, it remains a preferred choice across vessel segments and sizes.

Watch the recording of our two-stroke MAN ExpertTalk where we take a closer look at the new 10.7 engine platform, the improved gas return system, and general engine availability.

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.