Make your fuel gas supply system as efficient as it gets

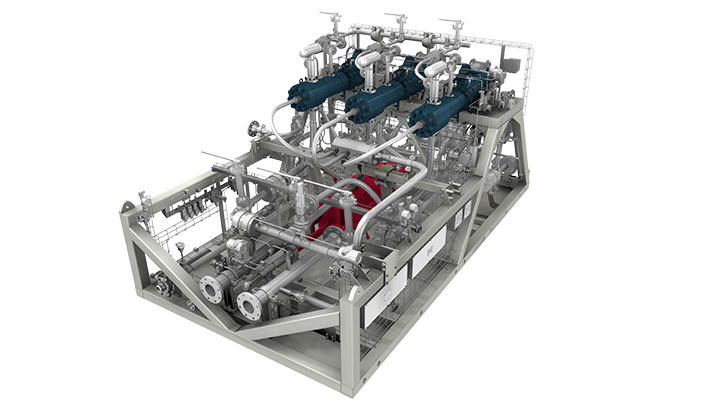

The ME-GI/GIE Pump Vaporiser Unit (PVU) is a standardized high-quality pump unit for supply of LNG or ethane to MAN B&W two-stroke ME-GI/GIE engines. With a compact and intelligent design, the PVU provides a lean design and integration in the fuel gas supply system (FGSS). PrimeServ Assist is an integrated part of the PVU and offers 24/7 monitoring as well as the option of servicing the unit remotely.

The working principle

The PVU is designed to supply LNG/ethane to the pressure and temperature required by the MAN two-stroke ME-GI/GIE engines. The PVU receives cryogenic LNG/ethane supplied by a cryogenic centrifugal pump and is subsequently pressurized by a high pressure reciprocating pump, consisting of three cylinders actuated by linear hydraulic pistons. The pressurized LNG/ethane flows through a compact printed circuit heat exchanger, in which it is heated by warm glycol water. Thereafter the gas is directed towards the gas valve train (GVT) and the engine. The gas pressure delivered to the engine is controlled by hydraulic flow control of the pump. Individual control of the three cryogenic pumps heads, means that the PVUs are still able to operate with only two cold-ends in service, providing the redundancy required by the market.

Key Benefits of the PVU

High reliability and easy maintenance

The PVU is designed for the highest standards of quality, hence ensuring the best reliability on the market. Easy maintenance is ensured by design with the operators in mind, providing easy access to exchange of spare parts. Further, PrimeServ Assist enables worldwide service surveillance through 24/7 monitoring and controlling.

Extended Time Between Overhaul

The PVU offers savings to the vessels OPEX through significant increase in Time Between Overhaul (TBO) compared to conventional high pressure pumps.

Embedded redundancy

Thanks to the compact and intelligent design of the PVU, the cryogenic pumps can be actuated individually, resulting in considerable saving in the complete FGSS. As a result of the PVU’s reduced size and weight, significant cost benefits in relation to installation costs are achieved.

Less Boil Off Gas

No High Pressure (HP) flow recirculation to LNG tank which leads to less boil off gas (BOG) in the tank.

Experience the PVU first-hand

With our new, interactive product experience you can now discover the functionality and all the benefits of the PVU first-hand!

Contact our experts

Get in touch with our

experts and find out how to future-proof your vessels with our dual-fuel engine

solutions.

Downloads

Download the Pump Vaporiser Unit MK II Project Guide

Download PVU Poster

-

ME-GI/GIE pump vaporiser unit for LNG and ethanepdf, 3716 KB

Explore more topics

-

LNG

LNG stands for liquefied natural gas, natural gas transformed into a liquid state through a cooling process. In its liquid form, natural gas has a significantly smaller volume for export, shipping, and storage. It is a low-emission, clean-burning fossil fuel that can be used for marine propulsion and transportation and regasified after delivery to a terminal.

-

LNG gas supply

Learn how LNG supply and bunker systems from MAN Energy Solutions help to boost your business.

-

LNG marine applications

MAN Energy Solutions handles a broad range of vessel applications - from container vessels and bulk carriers to highly specialized vessels like LNG carriers

-

-

PrimeServ Assist

PrimeServ Assist, a monitoring and advisory service powered by MAN CEON, helps to optimize performance and uptime through real-time data, AI, and OEM, expert support.

-

Two-stroke engines

Take advantage of optimal fuel prices and maximize the investment value of your vessel with a dual-fuel retrofit conversion from MAN PrimeServ

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.