Reduce your carbon footprint with methanol GenSets: MAN L21/31DF-M and the new MAN L27/38DF-M

Methanol is a leading alternative fuel in the quest to decarbonize the maritime industry. Responding to growing demand, we present our perfectly harmonized methanol GenSets.

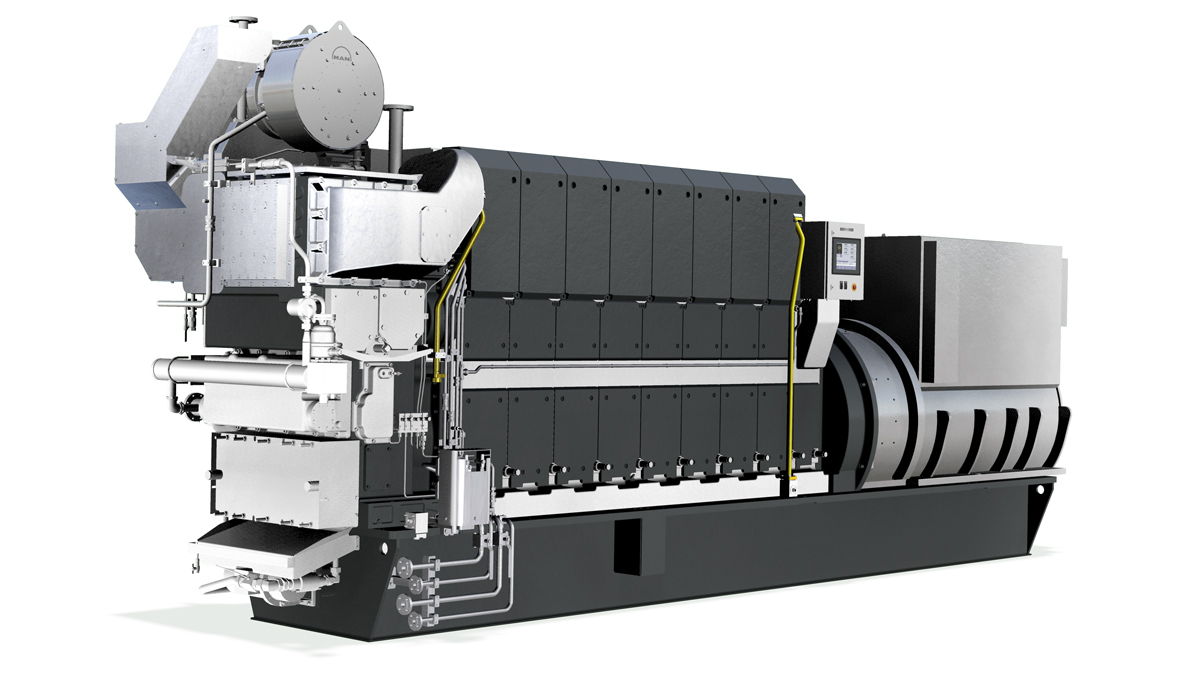

The MAN L21/31DF-M was the first small-bore dual-fuel methanol GenSet in our portfolio. And the new MAN L27/38DF-M is the next milestone and addition to our small-bore engine portfolio.

MAN Energy Solutions in Frederikshavn, Denmark is home of the MAN L21/31DF-M, our first small-bore GenSet fueled by methanol.

Proven design

The foundation of both engines are the trusted and proven L21/31 and L27/38 GenSets, which have jointly accumulated more than 290 million operating hours, with thousands of engines in service.

Key benefits

Perfect design features for efficient and reliable operation

These engines are based on the existing L21/31 and L27/38 GenSets and their well-established technology, with thousands of engines in service and more than 110 million operating hours so far.

The port fuel injection (PFI) concept of the MAN L21/31DF-M uses proven components, providing additional simplicity and an attractive capital outlay. The long time between overhauls (TBO) gives you flexibility for maintenance planning as well as saving time and costs.

The MAN L27/38DF-M is more powerful and can be used as a GenSet or for diesel-electric propulsion. The design supports an optimal methanol fuel share with only minimum amounts of fuel oil acting as pilot oil.

Technical specifications – MAN L21/31DF-M

| Description | Main data |

Bore | 210 mm |

| Stroke | 310 mm |

| Speed | 900 / 1,000 rpm (60 Hz / 50 Hz) |

| Output | 1,000 – 1,980 kW |

| Cylinder configurator | 5 – 6 – 7 – 8 – 9 |

| Available fuels | HFO, MDO, MGO, LSFO, ULSFO, Biofuels, MeOH |

| Emission limit | IMO Tier III with SCR after-treatment |

Optimized port fuel injection

The port fuel injection (PFI) system uses a methanol injection nozzle installed outside the combustion chamber. This simplified design removes the risk of blocked nozzles in diesel mode and reduces investment costs thanks to its easy installation and integration with standardized components.

MAN SaCoS control system and cybersecurity

The safety and control system MAN SaCoS supports a fast and reliable data-transfer between the engine and the power management system in the control room by easy cable connection.

The engine control system is attached to the engine and features an intuitive user interface and a colour display in different languages. The electric speed governor enables fast response.

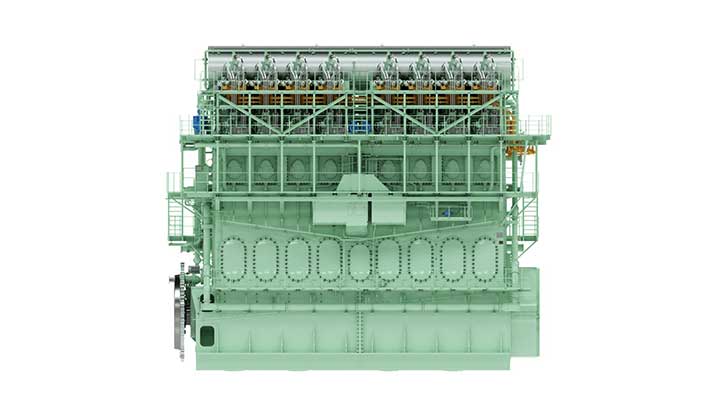

Perfect match for MAN B&W ME-LGIM two-stroke methanol engine

The first MAN B&W ME-LGIM came into service in 2016. Since then, we have accumulated more than half a million running hours on methanol alone, which provides a solid base for new developments. The L21/31DF-M is a perfect match for this methanol-fueled propulsion engine.

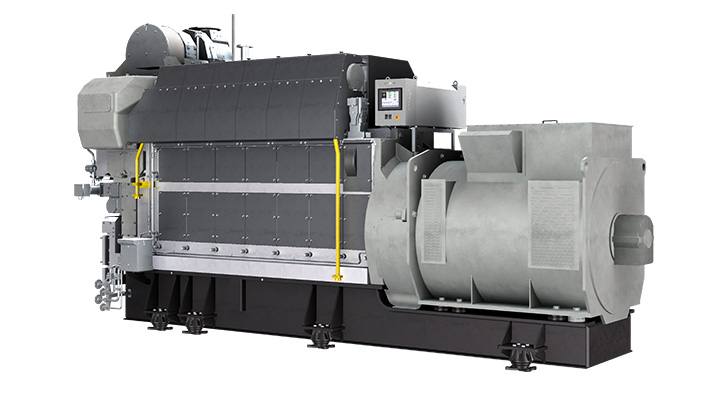

Technical specifications – MAN L27/38DF-M

| Description | Main data |

Bore | 270 mm |

| Stroke | 380 mm |

| Speed | 720 / 750 / 900 rpm |

| Output | 1,980 - 3,690 kW |

| Cylinder configurator | 6 – 7 – 8 – 9 |

| Available fuels | HFO, MDO, MGO, LSFO, ULSFO, Biofuels, MeOH |

| Emission limit | IMO Tier II, IMO Tier III with SCR after-treatment |

Low-pressure fuel supply system

The methanol supply system for L27/38DF-M is a cost-optimised low-pressure system, effectively making it a profitable solution providing a lower capex.

Increased fuel flexibility

The possibility to operate engines on methanol as a drop-in fuel means that e-methanol and bio-methanol increase the fuel flexibility of the new engine and the potential of methanol as an option for GenSet applications on large merchant marine vessels as well as for propulsion solutions for smaller vessel types.

MAN SaCoS control system and cybersecurity

The safety and control system MAN SaCoS supports a fast and reliable data-transfer between the engine and the power management system in the control room by easy cable connection.

The engine control system is attached to the engine and features an intuitive user interface and a colour display in different languages. The electric speed governor enables fast response.

What makes the new methanol-fueled MAN L21/31DF-M GenSet special?

Watch our 3D engine animation to find out more about the working principles, and also the Port Fuel Injection system.

Service solutions for your equipment

MAN PrimeServ offers a range of modernization solutions for optimizing the reliability, availability, and economic efficiency. MAN’s upgrade and retrofit solutions are tailor-made to customers’ specific applications and equipment.

Are you ready for green methanol?

Newbuild or retrofit? What are the costs? What are the benefits? Take the lead in sustainable shipping by contacting us today!

Continue reading

Inside the making of a methanol GenSet

Related products

-

Alternative fuels

Operate your in service engines with Alternative Fuels: Unleash Carbon-Free & Carbon-Neutral Solutions for MAN, B&W and S.E.M.T. Pielstick engines. Achieve Fuel Flexibility for Existing Systems!

-

Four-stroke small-bore engines

With our small-bore engines, you are prepared for whatever lies ahead.

-

MAN B&W ME-LGIM

The MAN B&W ME-LGIM is a two-stroke, dual fuel engine that runs on both methanol and conventional fuels.

-

Marine GenSets

Get an overview of the MAN GenSets, the powerful four-stroke auxiliary engines! Take your business to the next level.

Related News

-

Tuesday, February 18, 2025

Type Approval Test Marks Important Milestone for Methanol GenSet

Dual-Fuel methanol MAN L21/31DF-M engine passes milestone in China -

Monday, April 15, 2024

Methanol-Fuelled MAN 21/31DF-M GenSet Secures First Propulsion Order

Breakthrough order of 3 × MAN 21/31DF-M units for chemical tanker propulsion -

Monday, March 4, 2024

Signing Ceremony Expands Dual-Fuel Methanol Agreement with CCS

New sub-agreement supports development project for new MAN 21/31DF-M engine -

Thursday, February 15, 2024

MAN 21/31 Mk2 PLO GenSets for Antarctica Cruise Ship

Chilean tour operator, Antarctica21, chooses MAN engines once more for diesel-electric set-up for new 94 metre newbuild; follows similar ship from 2019 with same engine type

Set course to net zero with methanol GenSets - MAN L21/31DF-M

Watch the recording of our MAN ExpertTalk, where we introduced our new engine type: the small-bore four-stroke MAN L21/31DF-M GenSet for methanol operation.

You can look forward to hearing

about this new GenSet type, the Port Fuel Injection (PFI) concept, the fuel gas supply system and the possibility to operate these GenSets on green methanol and biofuel oils.