Engineers in Denmark are now making shipboard power low-emission too with a four-stroke dual-fuel methanol genset

With the first two-stroke dual-fuel MAN B&W ME-LGIM methanol engines propelling large container ships across oceans, MAN engineers from Holeby and Frederikshavn, Denmark, are now developing the ideal match for onboard power: a small-bore GenSet capable of running on conventional fuel, biofuels and green methanol.

By Niels Anner

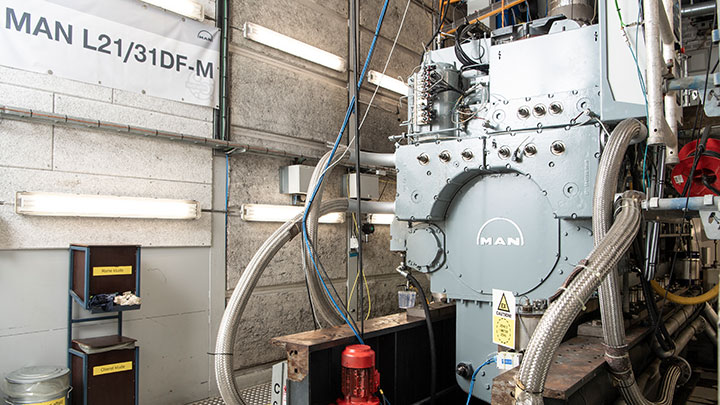

It began three years ago with a question: Can we make shipboard power low-emission too? Now, in Frederikshavn, Denmark, full scale trials are already being completed with a test methanol GenSet converted from a conventional MAN L21/31 engine – a perfect match for vessels with a methanol-fueled main engine.

Today, the small-bore four-stroke engineering team from Holeby is conducting tests on the seamless fuel shift from diesel to methanol. Upstairs in the control room, they’re monitoring all processes to make sure the operation is running smoothly. While downstairs in hall number 2, where it’s a scorching 35°C, the GenSet is humming along.

Combining a methanol-ready GenSet with a methanol-ready two-stroke engine brings clean power to every part of a vessel.

“The MAN L21/31 DF-M is the first small-bore, four-stroke methanol engine in our portfolio,” says Michael Køel Andersen, “and the first in the world at the 1,000- to 1,980-kilowatt power range.” Køel Andersen is MAN Energy Solutions’ Head of Four-Stroke Testing & Control in Holeby. Over the past three years, he and his team have been developing this dual-fuel GenSet with the goal of reducing a ship’s carbon footprint with green methanol.

“Methanol is a key green fuel for the maritime energy transition,” says Andersen, “and combining a methanol-fueled GenSet with a methanol-ready two-stroke engine brings clean power to every part of a vessel.”

Adopting methanol for diesel GenSets

GenSets – also known as auxiliary engines – are used for electrical power generation to run a variety of systems and equipment on board, such as lights, air conditioning, water pumps, cranes – even steering. Unlike the main engine or prime mover, which needs to provide enough power to move a ship through water, GenSets are smaller, more flexible and fuel efficient, reducing a ship’s total operating costs.

Market perception for the new GenSet is very positive, says Hakon Juel Hansen, Promotion Manager & Business Development, Small-Bore GenSets at MAN Energy Solutions in Copenhagen. “Our teams have a lot experience bringing new fuel and engine technologies to the market. In fact, we’ve been working with methanol-powered main engines for nearly a decade now, and we’ve drawn on this experience and applied years of knowledge to the methanol GenSets.”

The new methanol GenSet is based on a classic, reliable standard that already has more than 110 million hours in commercial operation. ©Gorm Branderup

In evaluating the right technology and the best business case for a dual-fuel methanol GenSet, the team found that using a proven and highly reliable small-bore diesel engine was the best foundation: The L21/31 GenSet that has already accumulated over 110 million operating hours with thousands of units in service.

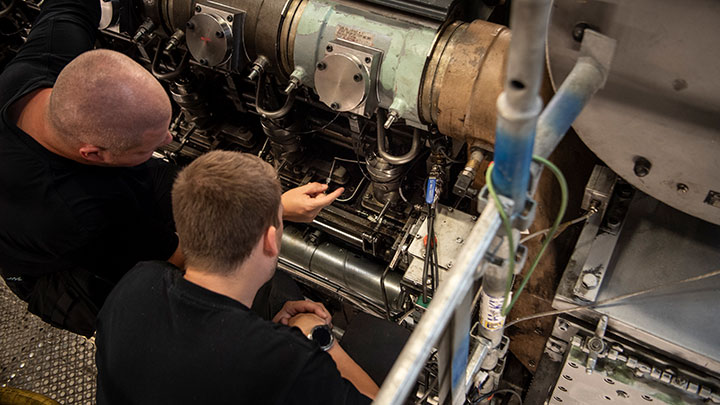

The conversion to methanol, however, wasn’t without its challenges, says Køel Andersen. “The biggest engineering challenge was the adaptation of our control system. Where could we find the space for injectors? Where could the ports be installed? The whole infrastructure is equipped with double-wall piping and the external system with a fuel valve train and nitrogen purging. It was a huge challenge, but we found the solution.”

We have a complete decarbonization solution for shipping in the pipeline.

The methanol GenSet retains all the features of the original, explains Andersen, such as long time between overhauls (TBOs). Plus, it offers online monitoring with an advanced SaCoS electronic control system and can run on a combination of fuels, including diesel, biofuel and methanol, making it a very flexible solution.

The biggest challenge for the MAN Energy Solutions engineers was to find enough space for the port fuel injectors. ©Gorm Branderup

The advantages of low-pressure port fuel injection

While the fuel shift test continues, Andersen points out the yellow pipes feeding methanol into the engine: “The next test will give us a complete visualization of our fuel mapping, where we can show the values for the mix of green methanol with diesel injection or for biofuel as a pilot inject to start combustion.”

Hakon Juel Hansen calls attention to another feaure of the new GenSet. “With a low-pressure port fuel injection (PFI) concept, we’re able to supply fuel safely at low pressures and cut capital expenditures for our customers.”

There are very few limitations on the type of merchant vessel this engine can be used on.

This was a key factor in the first order for the new GenSet: “We received an order from China Merchants Heavy Industry for six small-bore, seven-cylinder L21/31 DF-M, with the first delivery due in 2025,” says Hansen. The order is in conjunction with two Pure Car and Truck Carriers powered by MAN B&W ME-LGIM prime movers, which shows the potential for methanol: “With both main engines and GenSets running on green methanol, we have a complete decarbonization solution for shipping in the pipeline.”

The new MAN L21/31DF-M GenSet is based on the proven L21/31 GenSet that already accumulated over 110 million operating hours with thousands of units in service. ©Gorm Branderup

Meeting demand for greener transportation

The testbed here in Frederikshavn was designed in 2023, and the team has now been conducting full-scale engine tests for several months. R&D Engineer Warley Thomsen has been part of the project from early on, which began with a feasibility study just three years ago in 2020. Then after a single-cylinder test in 2022, says Thomsen, things progressed quickly: “We now have everything in place to optimize the engine’s operation and performance. And there are very few limitations on the type of merchant vessel this engine can be used on.”

Thomsen adds that retrofitting GenSets to run on methanol will also be an option starting in 2025. The fact that the L21/31 DF-M is based on a diesel engine will make the conversion easier. Moreover, says Hakon Juel Hansen, it will be easier to secure financing for vessels that run on green fuels. “Consumers are demanding more green transportation. Now, we have the right technology in the main engines and the GenSets”.

About the author

Niels Anner is an independent journalist based in Copenhagen, who writes on business, science, technology and society in Northern Europe.

Set course to net zero with methanol

The maritime industry is decarbonizing and methanol is currently one of the leading fuels among the alternative fuel solutions. Following the market demand and rising interest, we hereby introduce the new MAN L21/31DF-M methanol GenSet - the first small-bore dual-fuel methanol GenSet in our portfolio.

Explore more topics

-

The latest-generation wind turbine installation vessel

A new wind turbine installation vessel with a customized-engine configuration lets offshore wind contractor Cadeler transport and lift more powerful turbines in even rougher locations – and they’re saving emissions while they are at it.

-

Hapag Lloyd LNG container vessel

Hapag-Lloyd’s new LNG-powered containership cuts emissions by a quarter immediately and by 95 percent with green methane

-

Heidelberg Materials: First CCS plant for cement industry

The first CCS facility for cement production in Brevik, Norway, is paving the way for carbon-neutral industrial processes.

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.