The power of net zero

Future fuels are ready to be used by the energy industry to achieve climate targets. At MAN Energy Solutions, we make engines that run on future fuels, such as green hydrogen and its derivatives including synthetic natural gas (SNG), green ammonia, and green methanol. We also provide the means of producing the net-zero fuels themselves. We are ready to help you decarbonize – now.

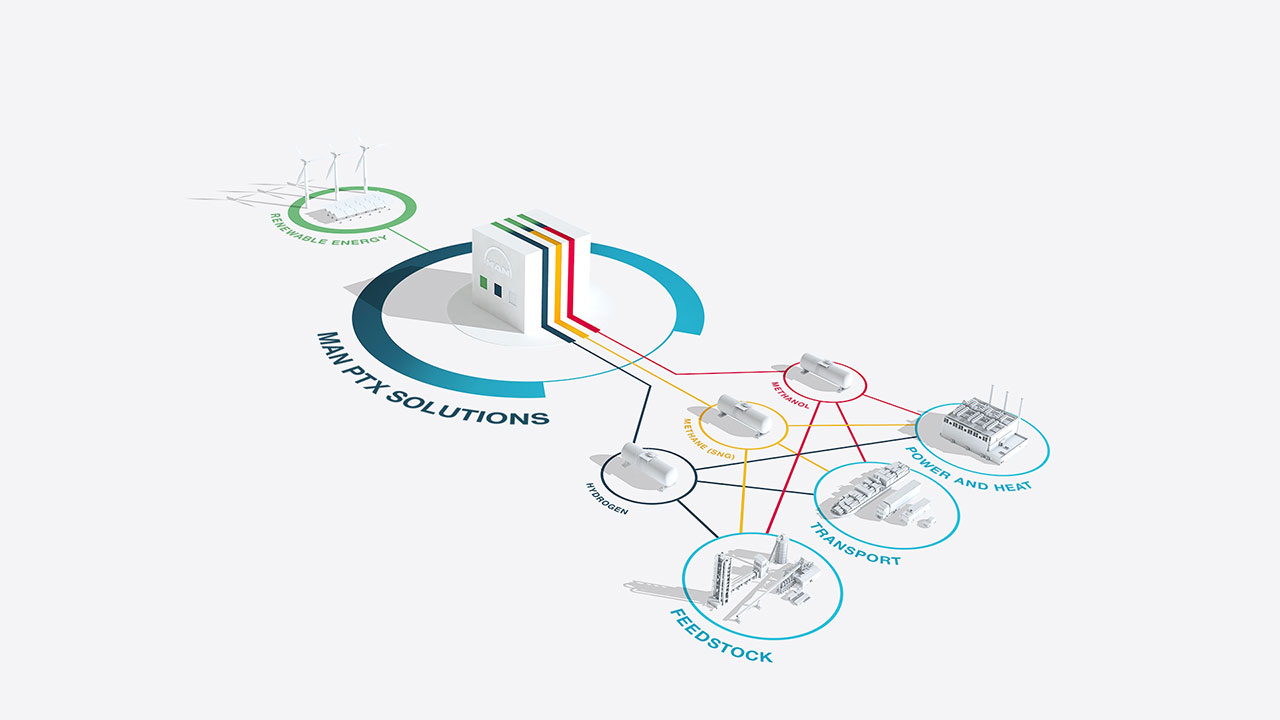

Power-to-X – at the crossroads of net zero

Future fuels are necessary in order to decarbonize sectors that are difficult or impossible to electrify. Power-to-X processes enable renewable energy sources to be converted into green fuels such as SNG, methanol or hydrogen, by making it possible to store and transport them.

MAN Energy Solutions has considerable expertise in the manufacture of reactor systems for the production of synthetic fuels, as well as numerous references in methanol synthesis. In the first process step, electrolyzers use renewable energy to split water molecules into their basic components of oxygen and hydrogen. The resulting green hydrogen is then either used directly as fuel or further processed, becoming the basis for many other future fuel types.

Hydrogen value chain

See how MAN Energy Solutions is driving the development of green hydrogen technologies: producing, transporting, storing and converting green hydrogen into other net-zero fuels.

Hydrogen

Green hydrogen is CO2-neutral. Its role is especially important in the process industry, in transport, and in power generation and heat supply applications where direct electrification is not possible.

SNG and biogas

Often regarded as bridging fuels, synthetic natural gas and biogas have the same low NOx, SOx, and particulate matter emissions as LNG, but they can be carbon-neutral.

Methanol

Green methanol is produced using only renewable sources, and can reduce carbon emissions by up to 95 %. It is a clean-burning and cost-effective fuel, since it can be used with existing infrastructure.

Ammonia

When produced from renewable energy sources such as wind or solar power, burning ammonia releases almost zero carbon and SOx emissions. It is expected to become an important fuel for power generation.

Biofuel

Being nearly 100 % carbon-neutral and fully renewable, biofuels are an attractive option for the energy transition. They are easy to transport, store, and handle, and can be used as drop-in fuels.

Products

Electrolyzers

Green hydrogen is made by electrolyzing water using renewable energy sources. The proton exchange membrane electrolyzers (PEM electrolyzers) used for this process are made by MAN Energy Solutions and its subsidiary Quest One. The hydrogen produced

can then be used further in MAN power-to-X solutions.

Chemical reactors

With over 60 years of experience, we are one of the leading manufacturers of tailor-made chemical reactors for the conversion of renewables into future fuels. Our water-, gas-, and oil-cooled tubular reactors are key components in power-to-X processes.

Components

Gas engines

We regard natural gas as a transition fuel, since it is easy to adapt existing equipment to carbon-neutral SNG. MAN gas engines can already use SNG or biogas, and some models can even run on admixture of up to 25% hydrogen.

Compressors

Hydrogen-based processes require centrifugal and screw compressors to manage certain volume flows efficiently. MAN has extensive equipment and experience in compression for hydrogen, ammonia, SNG, methanol, and more.

Life-cycle concept enables gradual transition for engines

MAN Energy Solutions traditionally takes a life-cycle approach to product design, which also applies to future fuels.

When it comes to engines, we are always thinking about how to improve the existing engine fleet with retrofits. MAN gas engines already in operation can be retrofitted for hydrogen admixture by upgrading the automation and adding additional ACC (Adaptive Combustion Control) sensors.

Contact our MAN Energy & Storage support team

Interested in decarbonized power generation?

We help power plant operators benefit from a multitude of synthetically manufactured climate-neutral fuels. Our R&D efforts are focused on maximum operational flexibility and keeping our products future-proof.

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.