Transforming onshore applications

MAN Cryo is your go-to provider of comprehensive cryogenic solutions for power plant and industrial applications. We engineer efficient and economical cryogenic solutions for liquefaction, regasification storage, bunkering/loading, and hydrogen production. MAN Cryo provides all the associated services, such as design, quality assurance, project management, and commissioning.

Customise our cryogenic solutions for your needs

Power plants

We specialize in delivering modular and scalable solutions that cater to a wide range of output requirements, spanning from 10 MW to 200 MW. MAN gas-powered, four-stroke engines are now H2-ready and can be operated in stationary mode with a hydrogen content of up to 25% by volume in a gas / fuel mix. This means that, in combination with our modular skid-mounted supply and storage solutions, we can provide gas supply and storage solutions for any type of consumer. Our services include engineering, project management, and commissioning.

Onshore hydrogen applications

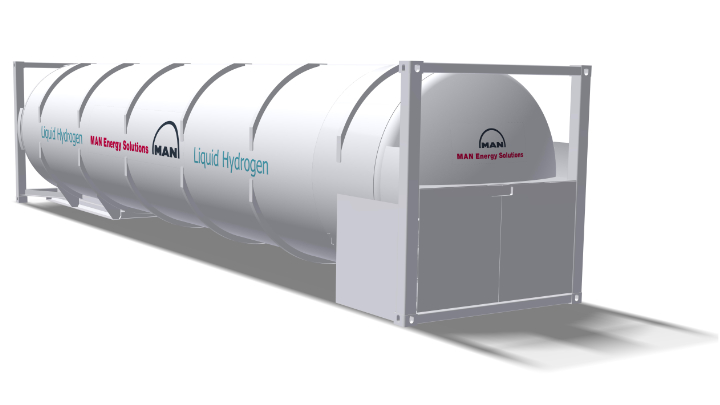

Our LH2 offering includes hydrogen generation from renewable sources with electrolyzers from Quest One, compressors for high-pressure storage, liquefaction systems, cryogenic storage, LH2 pump solutions for transfer and supply, and LH2 ISO container solutions.

Onshore liquefied gas applications

We offer systems for liquefied gases such as liquefied natural gas (LNG), liquefied hydrogen (LH2), liquefied oxygen (LOX) and liquefied nitrogen (LIN). The systems includes solutions for liquefaction, storage bunkering/loading and regasification and supply of gas to consumers.

Cryogenic solutions at a glance

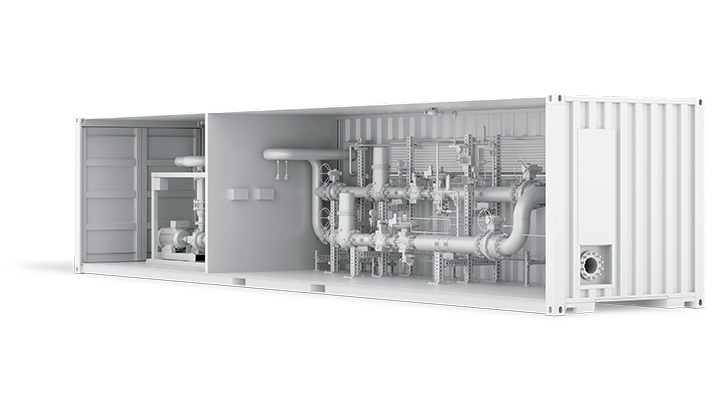

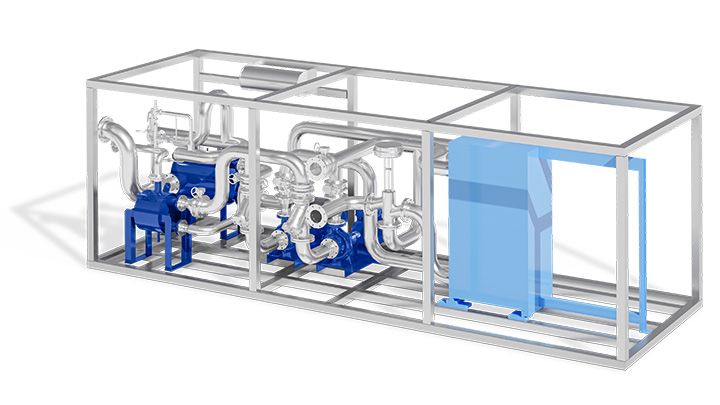

MAN LNG regasification system

MAN LNG regasification system

Liquefied methane (in the form of LBG, SNG or LNG) is delivered at -162°C. The MAN regasification system converts it back into a usable gas state. The system is able to import, store, regasify, and supply gas to consumers. We deliver a complete turnkey solution including all the equipment needed for safe operation and maintenance.

Benefits at a glance

- Modular and scalable design

- Easily customized with add-ons to meet client demands

- Turnkey delivery

- Worldwide service network

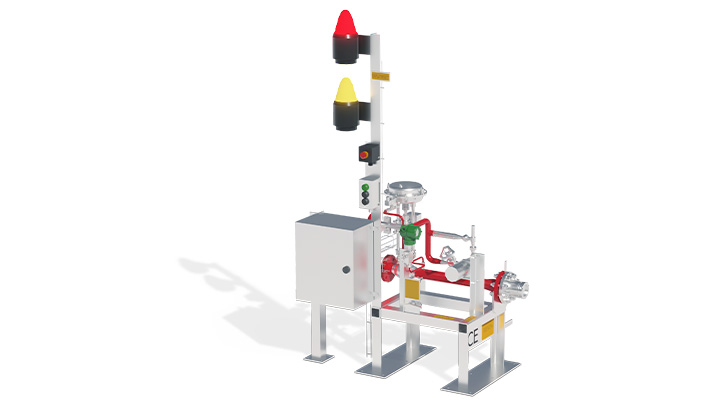

MAN PCU - Pressure Control Unit

MAN PCU - Pressure Control Unit

MAN PCU - Pressure Control Unit

MAN PCU handles pressure control, metering and odorization before supply to the gas grid. The system is supplied with all equipment and components installed in an ISO container for weather protection and ease of transport.

Benefits at a glance

- Complete gas treatment system supplied as one unit

- Includes all equipment, valves, piping, and instrumentation

- Safe operation and maintenance

- Weather protection of equipment inside tempered and ventilated container

MAN PSC - Power, safety, and control system

MAN PSC - Power, safety, and control system

MAN PSC - Power, safety, and control system

MAN PSC enables high availability and safe operation of gas processing plants and auxiliary systems. The containerized unit includes all equipment and functionalities needed for power supply, safety, control and maintenance.

Benefits at a glance

- Complete system in one unit

- Safe operation and maintenance

- Fast installation and easy start-up

- Remote operation

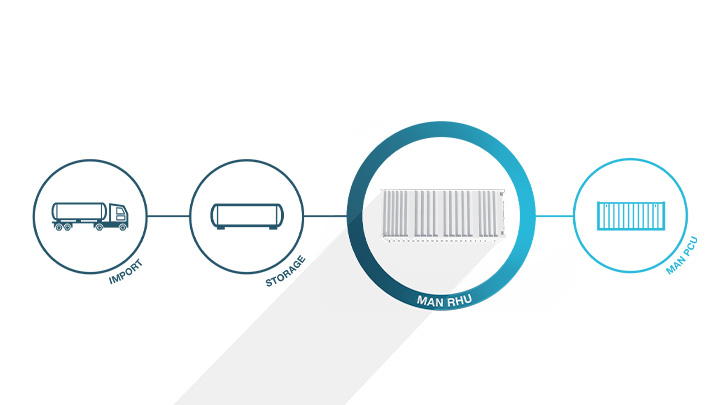

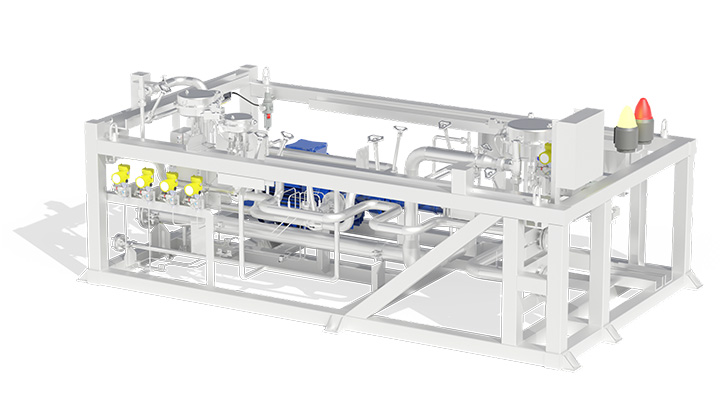

MAN RHU - Regasification and heat exchanger unit

MAN RHU - Regasification and heat exchanger unit

MAN RHU - Regasification and heat exchanger unit

MAN RHU handles vaporization and heat transfer to vaporizers. All equipment and components are installed on a steel frame and supplied as one complete unit. Excess heat from processes, district heating or steam can be used as energy sources.

Benefits at a glance

- Complete system in one unit

- Includes all equipment, valves, piping, and instrumentation

- Safe operation and maintenance

- Available in three sizes

- All instrumentation and electrical wiring terminated at junction boxes

- One pneumatic connection for all air consumers in the container

MAN W50 - Mobile tank unloading unit

MAN W50 - Mobile tank unloading unit

MAN W50 - Mobile tank unloading unit

MAN W50 enables safe import of LNG and LBG from mobile tanks to stationary tanks at satellite stations. All equipment and components are installed on a steel frame and supplied as one complete unit.

Benefits at a glance

- Complete import system in one unit

- Safe and standardized interface between mobile tank and satellite station

MAN W80P - Mobile tank unloading unit with pump

MAN W80P - Mobile tank unloading unit with pump

MAN W80P - Mobile tank unloading unit with pump

MAN W80P enables safe import of LNG and LBG from mobile tanks without onboard pumps to stationary tanks at satellite stations. The unit is supplied as a complete system with a stationary mounted transfer pump for unloading and a standalone pressure build-up vaporizer (PBU).

Benefits at a glance

- Complete import system in one unit

- Safe and standardized interface between mobile tank and satellite station

- All instrument and electrical wiring terminated at junction boxes

- One pneumatic connection for all air consumers

Liquefaction solutions

Liquefaction solutions

Liquefaction solutions

Onshore and offshore bunkering systems

Onshore and offshore bunkering systems

Onshore and offshore bunkering systems

With an onshore bunkering system, LNG is transferred to the end customer at the quay, pontoon, or jetty. We offer customized bunkering solutions depending on the application, required transfer rate, and volume.

Air gas solutions

Air gas solutions

Air gas solutions

- Support and backup systems for air separation plants

- Pump testing

- Special regasification at end customer

Hydrogen solutions

Hydrogen solutions

Hydrogen solutions

- Gas generation

- Liquefaction

- Regasification

- Bunker/Loading

- ISO transport container

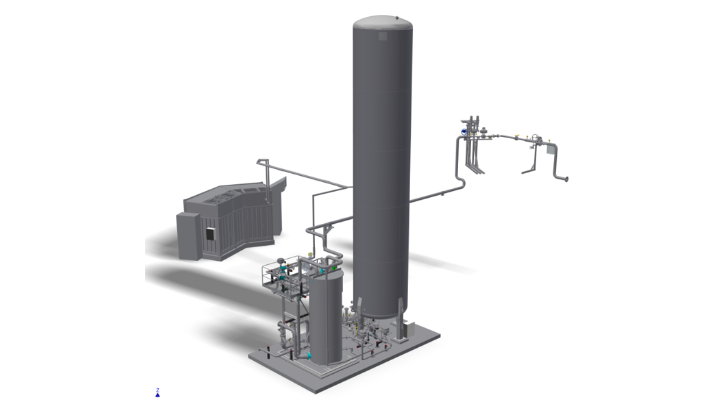

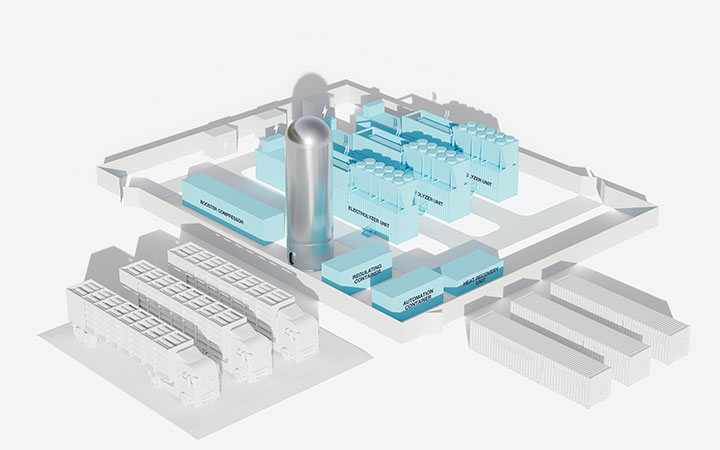

MAN Hydrogen Electrolyzer and Distribution System

MAN Hydrogen Electrolyzer and Distribution System

MAN Hydrogen Electrolyzer and Distribution System

Introducing MAN’s Hydrogen Electrolyzer & Distribution System (HEADS), a pioneering solution at the forefront of sustainability.

By harnessing the power of green energy sources, HEADS efficiently transforms them into hydrogen, offering a versatile and eco-friendly option for both local consumption and export. This technology represents a significant stride towards a more sustainable future, aligning perfectly with the global shift towards cleaner energy solutions.

Benefits at a glance

- Modular and scalable design

- Client-centric customization: Add-ons for diverse client needs

- All-in-one solution: Production, storage, and distribution of hydrogen from a single provider

- Quest One Modules: Integrated part of the system

- Turnkey delivery: Hassle-free from start to finish

- Global support: Benefit from our worldwide service network

Downloads

Talk to our experts

Learn how you can stay cool under pressure!

With our commitment to quality, reliability, and innovation, we strive

to deliver cryogenic solutions that drive efficiency, productivity, and

sustainability in the power plant and industrial sectors. Explore our

range of offerings and experience the expertise and excellence that sets

MAN Cryo apart.

Related news

-

Monday, June 24, 2024

MAN Cryo Supplies Fuel System for World’s First Hydrogen-Powered Superyacht

Newbuilding features below-deck liquid-hydrogen tanks and vaporization system in other industry first -

Tuesday, May 28, 2024

MAN Cryo to Design Hydrogen Supply for Net-Zero Norwegian Ferries

Torghatten to employ company’s expertise within detail design for bunkering systems, hydrogen piping and vent masts for newbuild vessels -

Thursday, April 11, 2024

Shipbuilding Projects with Ammonia Engines Firm Up

Japanese joint venture explores MAN B&W 60-bore ammonia engine for bulker -

Monday, January 22, 2024

MAN Cryo Wins Approval for Ammonia Fuel-Supply System

Latest collaboration with Yada Green Energy Solutions gets seal of approval from classification societies

Continue reading

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.