Make your existing vessels comply across the seas of maritime emission regulations

Navigate your existing fleet's emissions and compliance with MAN PrimeServ. Explore how our leading solutions can steer your in-service vessels safely across seas of decarbonization regulations, including the Carbon Intensity Indicator (CII), the FuelEU Maritime and EU Emission Trading System (EU ETS) directives, and beyond. Improve your vessels’ fuel savings and operational efficiency today and learn how to navigate decarbonization with MAN PrimeServ.

Carbon Intensity Indicator (CII)

What is the CII regulation?

The Carbon Intensity Indicator (CII) by the International Maritime Organization (IMO) measures ships’ carbon efficiency, calculating CO2 emissions per tonne-mile of cargo. Ships are rated from A (most efficient) to E (least efficient), encouraging greener practices.

How can ships improve their energy efficiency?

Ships can improve their CII rating by optimizing speed, using sustainable fuels, and installing energy-saving technologies. Performance is recorded in the Ship Energy Efficiency Management Plan (SEEMP), with annual reviews to ensure continuous improvement.

What does CII mean for compliance?

CII measures a ship’s CO2 emissions per cargo capacity and nautical mile, with stricter thresholds over time. Ships rated D for three years or E for one year must submit a corrective plan to achieve a C rating or better. This applies to ships over 5,000 GT.

EU Emission Trading System (EU ETS)

What is the EU ETS (EU Emission Trading System) regulation?

The EU Emission Trading System (EU ETS) requires shipping companies to report CO2 emissions and hold emission allowances. Ships are rated from A to E based on their Carbon Intensity Indicator (CII), with performance recorded in the Ship Energy Efficiency Management Plan (SEEMP).

What is the impact on your business?

Customers will pay for their emissions, with costs rising from 90 Euros per ton of CO2 now to about 280 Euros by 2026. As emission quotas decrease, the Carbon Price will increase.

What does EU ETS mean for compliance?

Shipping companies must report CO2 emissions and hold enough allowances to cover them. Non-compliance can result in fines and operational restrictions, making it essential to adapt to these regulations.

FuelEU Maritime

What is the FuelEU maritime initiative?

The EU Fuel regulation, part of the FuelEU Maritime initiative, aims to reduce the carbon intensity of maritime fuels. It sets targets for greenhouse gas emission reductions, promotes renewable and low-carbon fuels, mandates on-shore power supply for ships in major EU ports, and includes penalties and incentives for compliance. This aligns with the EU’s Fit for 55 package and European Climate Law.

What is the impact on your business?

The regulation requires businesses to adopt renewable and low-carbon fuels, potentially necessitating investments in new fuel technologies and infrastructure, especially for on-shore power supply at major EU ports.

What does FuelEU mean for compliance?

Shipping companies must meet stringent standards to reduce carbon intensity, using low-carbon and renewable fuels by set deadlines. Non-compliance can result in fines and operational restrictions. Maritime operators need to upgrade fuel systems and adopt compliant fuels to align with EU regulations for a sustainable maritime sector.

Pioneering compliance in sustainable maritime operations

MAN Energy Solutions equips maritime operators with advanced technologies and services designed to meet the demands of new environmental regulations. Our solutions, ranging from fuel-efficient retrofits to cutting-edge digital monitoring systems, ensure that your fleet complies with regulations like EU ETS and FuelEU and advances toward greater sustainability and operational excellence. We offer tailored assessments and implementations, supported by a global service network, to help you optimize performance and compliance seamlessly.

1.

Your situation now

2.

Analysis by the OEM designer experts

3.

Solutions Mix (Digital, Retrofit, Spare Parts)

4.

Achieve compliance with regulations

Explore

Explore powerful decarbonization solutions, designed by the original manufacture

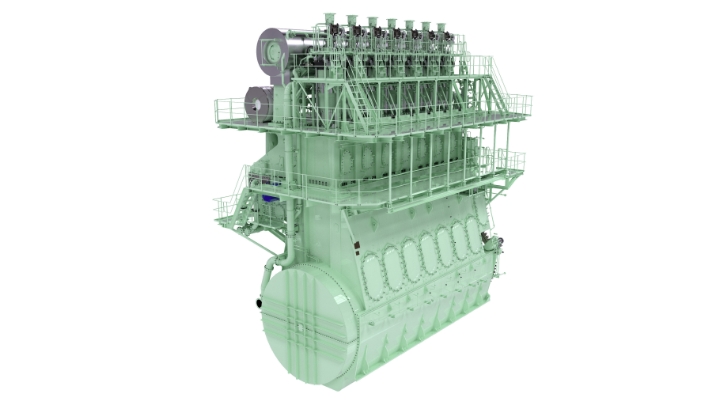

Two-stroke solutions

MC/MC-C retrofit solutions

MAN EcoCam

The MAN EcoCam is a low-cost, simple fuel saving product. This low-load optimized virtual cam gives you lower emissions and instant fuel savings between 10% and 60% load. The MAN EcoCam enables efficient slow steaming with operational flexibility for mechanical engines and is available for engines with a wide exhaust camshaft.

MAN EcoNozzle

Fuel savings with the MAN EcoNozzle, the latest addition to the new MAN Eco family designed to provide fuel savings in the entire load range! With this new concept fitted, your engine will have state-of–the-art combustion control.

PMI VIT

PMI VIT system is used for mechanically controlled MAN B&W two-stroke engines and ensures the optimal cylinder pressure by controlling fuel-injection timing via an electronic actuator on the VIT (variable injection timing) rack.

Flexible Turbocharger Cut-Out

The Flexible Turbocharger Cut-Out (TCCO) gives operators the option to disable one of the turbochargers for slow steaming operation. This improves the performance of the remaining turbochargers, thus reducing SFOC.

ME/ME-B/ME-C retrofit solutions

MAN EcoTuning

MAN EcoTuning is a tailor-engineered part-load tuning solution that significantly reduces fuel oil consumption, supporting fleet decarbonization and compliance with emission regulations like the Carbon Intensity Indicator and the EU Emissions Trading System. This retrofit tuning is specifically designed for MAN B&W two-stroke ME and ME-C engines, optimizing engine performance through software-based fine-tuning of the maximum combustion pressure.

MAN EcoTorque

Governor control to improve cylinder liner condition and lower fuel consumption. MAN EcoTorque improves the cylinder liner condition and fuel consumption by stabilizing the fuel index. This means that short-term external influences will not put excess strain on the engine, and the fuel index will remain steady.

Learn more

PMI Adaptive Cylinder Control

With PMI Adaptive Cylinder Control, MAN Energy Solutions is taking engine tuning to the next level. Using a new, patented algorithm, closed loop control ensures that each individual cylinder always operates at its optimal cylinder pressure. This gives you the best engine performance and lowest possible fuel consumption at all times.

Learn more

Flexible Turbocharger Cut-Out

The Flexible Turbocharger Cut-Out (TCCO) gives operators the option to disable one of the turbochargers for slow steaming operation. This improves the performance of the remaining turbochargers, thus reducing SFOC

PMI Auto-tuning

PMI Auto-tuning is used for electronically controlled MAN B&W two-stroke engines. This PMI system configuration ensures the optimal cylinder pressure by adjusting the fuel-injection timing and the opening of the exhaust valve.

Dual-Fuel Conversion

A dual-fuel conversion is one of the most effective ways to drive greater efficiency, profitability, and especially CII compliance. Reliability, greater efficiency and compliance with new environmental legislation are just some of the benefits our advanced retrofit solutions provide

Learn moreSpare Part Solutions

Maintenance kits

Correct use of Maintenance Kits assists in reducing fuel and lube oil consumption and ensures optimal energy utilization for propulsion or power generation. Continuous and preventive maintenance of engine components are absolutely key in supporting and maintaining an optimal CII rating.

Learn more

Cermet-coated piston ring

OEM piston rings are a critical part of your engine and play an important role in maintaining the performance of surrounding components, including emissions, fuel oil consumption and impacting your CII rating..

Learn more

MXPSS

By using the Docking Package Service Solution, you will always get the latest design, most optimized spare parts and thus optimal engine operation, cost savings and emission optimization. Thereby supporting and maintaining an optimal CII rating.

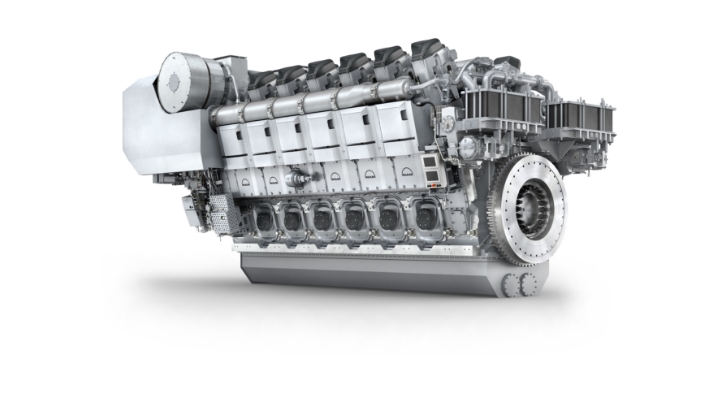

Four-stroke solutions

Roadmap Solutions

Lifecycle upgrate (LCU)

The retrofit solution that allows ship owners and operators to renew their MAN 48/60 engines and upgrade them to new MAN 51/60 engines. It includes the replacement of many components as well as upgrades to meet the latest regulations. It's a cost-effective solution to extend your engines' life, improving the safety, performance, and reliability. In addition, it reduces fuel consumption and maintenance costs, allowing for greater efficiency and cost savings.

Learn more

Dual Fuel Conversion

This retrofit delivers complete dual fuel conversion packages with upgraded turbochargers. A customized adaption of gas related plant equipment, engine control and safety installations allows reducing the carbon footprint in line with international and local regulations. Nitrogen oxides (NOx) are also low thanks to an optimized combustion in gas mode.

Learn moreRetrofit Solutions

AdaptiVIT

The AdaptiVIT system uses combustion parameters to determine the injection timing. This guarantees the most efficient combustion process fully complying with the specified emission regulations. Permanent cylinder pressure measurement is the basic parameter of the AdaptiVIT system. Injection timing is permanently closed-loop controlled by the stand-alone system AdaptiVIT.

Engine Part Load Optimization (EPLO)

This retrofit aims to improve the efficiency between 50% and 65% maximum continuous rating (MCR) with a modification of the SaCoS control system. This technology uses the features of the pneumatic variable injection timing (VIT), and no scope of supply is required with this is installed. A new emission test was carried out and approved: the retrofitted engine will belong to a different engine group, and the new technical file is included in the offer for each engine variant.

Bio / Synthetic Fuel Upgrade

This solution enables the engine to run safely and efficiently with a non-petroleum derived fuel without replacing the main components of the engine. This permits to reduce the carbon footprint helping with international and regional emission regulations. A fuel analysis must be provided to build the best customized solution and ensure reliable running of the engine.

Spare Parts Solutions

Maintenance Kits

Correct use of Maintenance Kits assists in reducing fuel and lube oil consumption and ensures optimal energy utilization for propulsion or power generation. Continuous and preventive maintenance of engine components are absolutely key in supporting and maintaining an optimal CII rating.

Overhaul Packages

By using overhaul packages, you will always get the latest design, most optimized spare parts and thus optimal engine operation, cost savings and emission optimization. Thereby supporting and maintaining an optimal CII rating

MK3 pump

The MK3 (Mark 3) Pump is an injection pump with a sealing ring around the plunger to avoid the lacquering effect. It is easy to retrofit on existing engines, best retrofit opportunity is during a scheduled pump maintenance interval. This improved conventional fuel injection system is compatible for MAN engine families 23/30, 32/40CD, 48/60 B, 48/60 TS, 51/60 and 58/64 CD. Whereof 48/60A is still being under development.

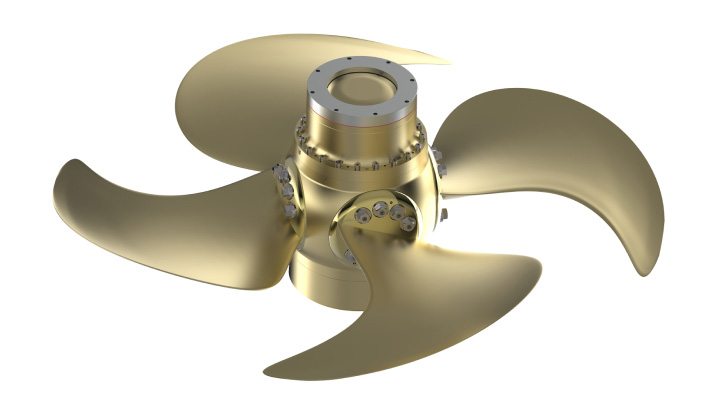

Propeller solutions

CP Propeller Upgrade

All engine configurations with MAN Alpha CPP and remote control system

Upgrade your CP propeller with the latest technology and hydrodynamic know-how. A CP propeller optimization provides great fuel-saving, allowing your vessel to meet stricter emission levels and CII requirements. This upgrade also potentially improves your energy class while optimizing your operational economy, providing a short return on investment.

Learn moreMAN EcoOptimizer

All engine configurations with MAN Alpha CPP and remote control system

The power required for propelling the ship and the corresponding SFOC of the main engine determines its total fuel oil consumption. Comparing the runs of the optimum propeller and engine curves will reveal that they do not coincide. One curve is optimal for the propeller and another one for the engine. MAN EcoOptimizer harmonizes both curves for optimal energy efficiency.

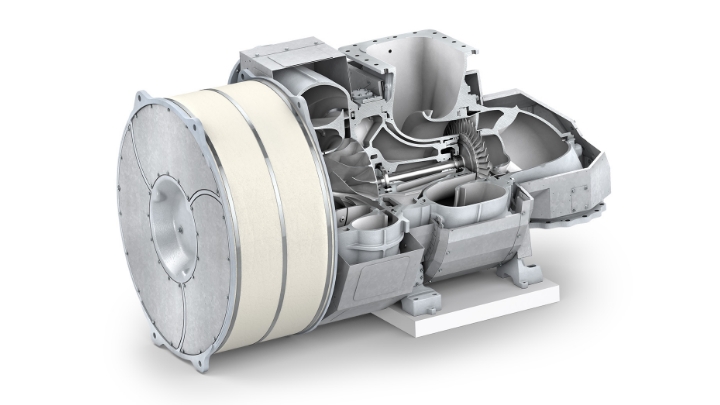

Turbocharger solutions

Turbocharger Retrofit

The existing turbocharger of any manufacturer will be replaced by a state of the art MAN turbocharger. Available for 2-stroke and 4-stroke engines on marine vessels and power plants. A turbocharger retrofit can give benefits including lower fuel consumption (especially when combined with other products), reduced exhaust gas temperature, optimized matching along with the load profile of the engine and extended overhaul and a new warranty.

Learn moreDiscover the success stories of our clients

Performance Measurement Indicator

Chevron retrofitted five of its vessels with an MAN Energy Solutions PMI system and allowed MAN Energy Solutions to review subsequent fuel consumption data. The result: 22 tonnes of fuel per day saved.

Get in touch now to start your path to CII compliance

Compliance requires effort. We, as the original manufacturer, can quickly deliver an actionable overview of what is needed to comply with CII, not only for now but also for the following decades.

Watch our recording on new fuel digital retrofit solution: MAN EcoTuning

Key Topics to explore:

- MAN EcoTuning: A digital retrofit solution for optimizing fleet performance and decarbonization by saving fuel, reducing emissions, and finetuning operations.

- PMI ACCo (ME-C): A digital retrofit solution for precise control of engine parameters that can support to improve reliability, durability, and your environmental compliance.