Enabling a scalable energy transition

The MAN B&W ME-LGIM two-stroke dual-fuel engine can run on methanol as well as conventional fuels. Specifically designed to meet the needs of the maritime industry, it is a versatile and scalable solution that is suited to a wide range of vessel types. Simple handling, storage, and bunkering of methanol, combined with relatively simple auxiliary systems and the potential to be carbon-neutral, makes it an attractive option for meeting decarbonization targets.

Proven two-stroke methanol engine design

Available either for newbuilds or for upgrading existing conventional fuel vessels, this engine represents a proven, refined engine design based on over 600,000 running hours on methanol alone. Methanol produced from renewable sources is an attractive marine fuel option due to its low carbon intensity. An engine using green methanol can even provide carbon-neutral propulsion.

Key benefits

A new design for efficient methanol combustion

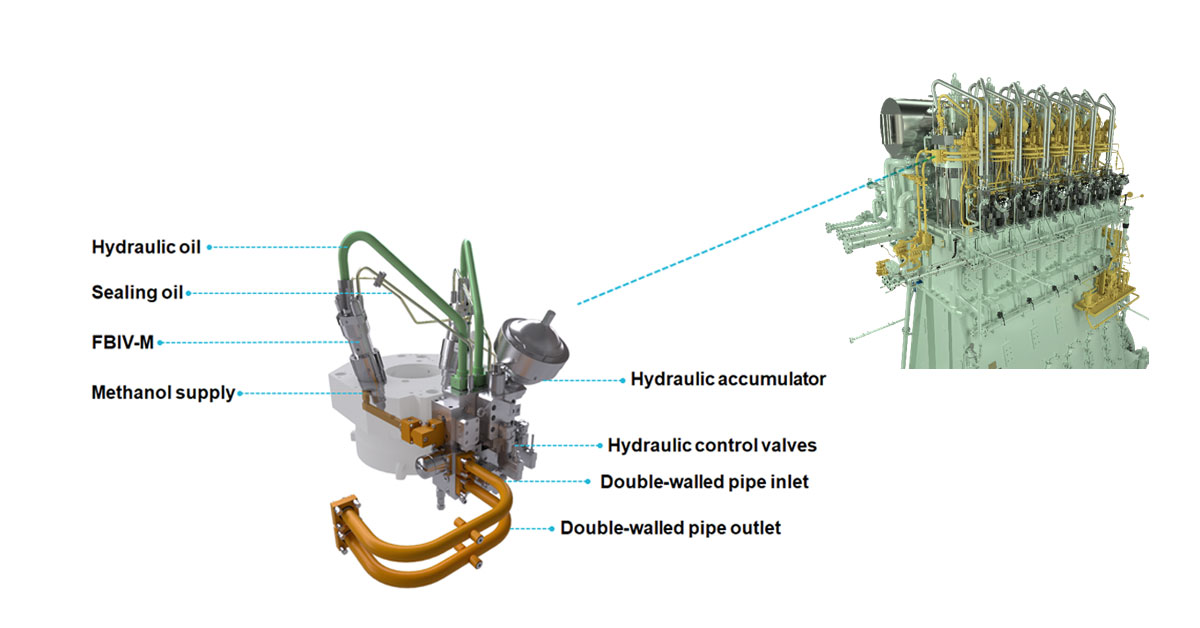

The ME-LGIM engine has inherited well-known components of our standard two-stroke diesel engine, like the ME-GI dual-fuel engine. Beneficial features of the standard MAN B&W two-stroke diesel engine have been retained. This illustration highlights methanol components and pipes that have been added to the cylinder top for methanol combustion.

The use of methanol as fuel type supports cost-effective vessel designs.

Moving together into a sustainable future

Learn more about the MAN B&W ME-LGIM engine

Continue reading

-

MAN B&W ME-LGIMpdf, 504 KB

Related products

Related News

Austal Chooses MAN 175D Propulsion for New High-Speed Catamaran Ferry

The Austal shipyard in Vietnam has ordered 4 × 16V175D-MM engines, delivering 2,720 kW at 1,800 rpm for water-jet propulsion, in connection with the building of a high-speed catamaran ferry for customer, the Degage Group. The 66-metre, 574-passenger ferry is scheduled for delivery in the first half of 2023 and will operate as the ‘Apetahi Express’ between Pape’ete (Tahiti) and Vaitape (Bora Bora) in French Polynesia. The new ferry will have a contracted top speed of 35.8 knots and a range of 360 nautical miles.

Tuanua Degage, President, Degage Group, said “These will be the first MAN engines in our fleet. We are very much looking forward to working with MAN Energy Solutions, and in particular the MAN PrimeServ New Zealand team, to ensure the highest levels of engine relaiblity and economy on this very demanding route.”

Ben Andres, Head of High-Speed Sales, MAN Energy Solutions, said: “This is an important milestone for the MAN 175D as it wins the favour of yet another, high-speed ferry application, this time with the Degage Group, an acknowledged leader in commercial maritime transportation and tourism. The 175D has a number of advantages that make it eminently suitable for such a technically demanding application, including its long times-between-overhaul, and its best-in-class fuel consumption.”

MAN PrimeServ, MAN Energy Solutions’ after-sales division, reports that it has already established service competence in the region in Auckland, where its local hub services 175D engines in operation at the New Zealand Navy. The same hub is located conveniently for maintenance and service support of the newbuilding ferry in Tahiti.

Technical Advantages

The MAN 175D engine has a number of advantages that make it suitable for HSC (High-Speed Craft) operation, including:

- very long TBOs for demanding ferry operation with continuous high average load,

- most competitive fuel consumption in the 2720 kW power range,

- lowest operating costs in class.

About the MAN 175D engine

MAN Energy Solutions has developed the MAN 175D engine range to supplement and complete its product portfolio in the maritime sector. In three variants of 12, 16 and 20 cylinders, the engine is available with an output ranging from 1,500 to 4,400 Kilowatts and is optimised for propelling ferries, offshore supply vessels, tug boats and other working vessels. Other market areas, such as super-yachts and naval marine applications are also served by additional, specialist model versions.

It is also an extremely eco-friendly engine, being designed from the outset with compliance to the latest, as well as future, exhaust-gas-emission requirements and utilises a very compact and flexible SCR system, which enables vessel designers to optimise space on board to the maximum.

Documents

-

PR Apetahi Express MAN 175D_EN

Contact

Nils Søholt

Trade Press Marine

Group Communications & MarktingMAN Energy SolutionsTeglholmsgade 412450 Copenhagen SVDenmark

nils.soeholt@man-es.com t +45 33 85 26 69Available languages

- DE ·

- EN

Get notified about press releases

Alternative fuels for your two-stroke powered vessel: Ammonia, methanol and methane in focus

Watch the recording of our latest MAN ExpertTalk on alternative fuels for large merchant marine vessels. Get insights into the most promising marine fuels of the expected future fuel mix for two-stroke vessels, namely ammonia, methanol and methane.

You can also look forward to hearing about the latest product developments and applications as well as reasons why these fuels have the potential to offer a straightforward path for the future maritime energy transition.