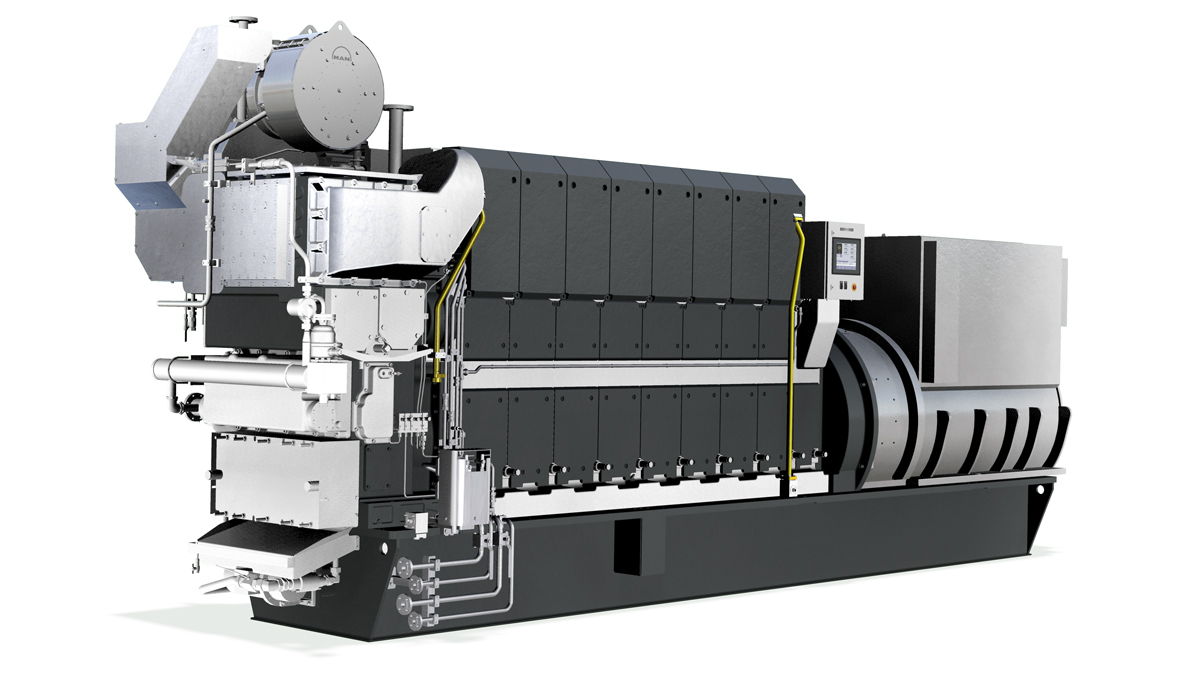

Reduce your carbon footprint with the new MAN L21/31DF-M methanol GenSet

The maritime industry is decarbonizing and methanol is currently one of the leading fuels among the alternative fuel solutions. Following the market demand and rising interest, we hereby introduce the new MAN L21/31DF-M methanol GenSet - the first small-bore dual-fuel methanol GenSet in our portfolio.

MAN Energy Solutions in Frederikshavn, Denmark is home of the MAN L21/31DF-M, our first small-bore GenSet fueled by methanol.

Proven GenSet design

The foundation of this new engine is based on the current L21/31 GenSet and its well-proven technology, which has already accumulated more than 110 million operating hours, with thousands of engines in service.

Key benefits

Perfect design features for efficient and reliable operation

The L21/31DF-M comes with a cost-optimised, low-flashpoint fuel supply system which makes it a competitive solution.

Furthermore, the port fuel injection (PFI) concept provides additional simplicity and an attractive capital outlay. And it is based on proven components.

Long time between overhaul intervals will save you time and costs on engine maintenance and will give you additional flexibility for the planning of your maintenance slots.

Technical specifications

| Description | Main data |

Bore | 210 mm |

| Stroke | 310 mm |

| Speed | 900 / 1,000 rpm (60 Hz / 50 Hz) |

| Output | 1,000 – 1,980 kW |

| Cylinder configurator | 5 – 6 – 7 – 8 – 9 |

| Available fuels | HFO, MDO, MGO, LSFO, ULSFO, Biofuels, MeOH |

| Emission limit | IMO Tier III with SCR after-treatment |

Optimized port fuel injection

The port fuel injection (PFI) system uses a methanol injection nozzle installed outside the combustion chamber. This simplified design removes the risk of blocked nozzles in diesel mode and reduces investment costs thanks to its easy installation and integration with standardized components.

MAN SaCoS control system and cybersecurity

MAN SaCoS ensures fast and reliable data-transfer between the engine and the power management system in the control room by easy cable connection.

The engine control system is attached to the engine and features a user-friendly color display in multiple languages. The electric speed governor enables fast response.

Perfect match for MAN B&W ME-LGIM two-stroke methanol engine

The first MAN B&W ME-LGIM came into service in 2016. Since then, we have accumulated more than half a million running hours on methanol alone, which provides a solid base for new developments. The L21/31DF-M is a perfect match for this methanol-fueled propulsion engine.

What makes the new methanol-fueled MAN L21/31DF-M GenSet special? Watch our 3D engine animation to find out more about the working principles, and also the Port Fuel Injection system.

Service solutions for your equipment

MAN PrimeServ offers a range of modernization solutions for optimizing the reliability, availability, and economic efficiency. MAN’s upgrade and retrofit solutions are tailor-made to customers’ specific applications and equipment.

Are you ready for green methanol?

Newbuild or retrofit? What are the costs? What are the benefits? Take the lead in sustainable shipping by contacting us today!

Continue reading

Inside the making of a methanol GenSet

Related products

-

Alternative fuels

Operate your in service engines with Alternative Fuels: Unleash Carbon-Free & Carbon-Neutral Solutions for MAN, B&W and S.E.M.T. Pielstick engines. Achieve Fuel Flexibility for Existing Systems!

-

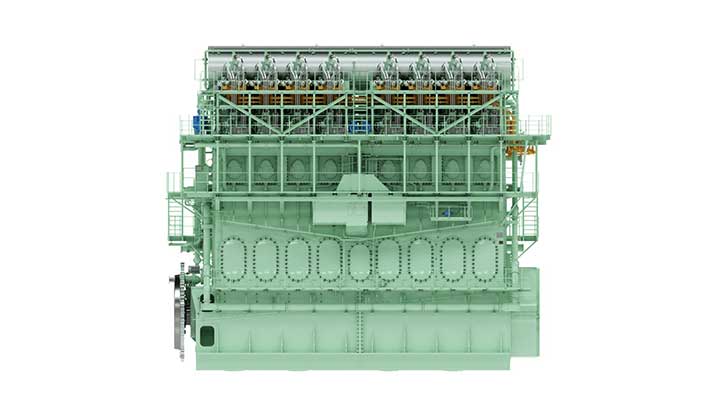

MAN B&W ME-LGIM

The MAN B&W ME-LGIM is a two-stroke, dual fuel engine that runs on both methanol and conventional fuels.

Related News

MAN Propulsion Package to Power Tanker Quartet

Fujian Mawei Shipbuilding and Xiamen Shipbuilding Industry in China have ordered 4 × MAN 10L32/44CR main engines in connection with the construction of 4 × 41,000 dwt oil-and-chemical tankers for German Tanker Shipping (GTS).

The construction of the 199 m Swedish Fartygskonstruktioner AB-designed newbuildings is set to start at Xiamen Shipbuilding with delivery scheduled from mid-2025 onward. The order includes options for an additional two vessels.

Each main engine will have a power output of 600 kW per cylinder and comes integrated with MAN Energy Solutions’ proprietary LP-SCR (Low-Pressure Selective Catalytic Reduction) system that delivers NOx-reduction rates of up to 90% in fulfilling the latest IMO environmental requirements. Each engine will drive an MAN Alpha VBS1260 CP propeller via a Flender GUCK-1560 gearbox.

Each vessel will also feature MAN auxiliary engines in the form of 2 × 8L23/30H Mk2 (at 900 rpm) and 1 × 6L23/30H Mk2 (at 720 rpm) GenSets. MAN Energy Solutions licensee, CSSC Marine Power Co., Ltd (CMP), will build these engines in China.

GTS Executive Management stated that it was very proud to continue its newbuild investment program, especially during the company’s 25th anniversary year, with its long and loyal partner, MAN Energy Solutions.

Lex Nijsen – Vice President, Marine Europe and Americas – MAN Energy Solutions, said: “This entire project is testimony to the excellent, decades-long cooperation between GTS and MAN Energy Solutions. It’s a notable feather in our cap to have been selected as propulsion-system supplier for these ice-classed newbuilds.”

Christian Kamm – Sales Manager Europe, Marine – MAN Augsburg, said: “The MAN 32/44CR engine maintains high efficiency at all times and there is no fuel penalty or de-rating when operating the SCR system, especially with HFO. This is in great part due to the lower temperature that MAN SCR solutions operate at and that meet the highest emission standards.”

Common-rail engines

MAN common-rail engines are capable of burning conventional fuels like HFO, MDO and MGO, as well as sustainable fuels like biodiesel (HVO and/or FAME). They are also designed so as to be ready for retrofit to methanol operation as green fuel should that be desired at a later stage. The 32/44CR’s SaCoS 5000 engine automation system also enables it to fulfil cyber security requirements and facilitates remote technical support.

MAN Alpha propeller

Colin Peesel – Head of Sales & Promotion, Germany – MAN Energy Solutions, added: “The combination of the MAN 10L32/44CR main engine and MAN Alpha CP propeller – including the intelligent Alphatronic 3000 propulsion-control system – will deliver a reliable, efficient and flexible solution, running the vessels at their optimal loadpoint in order to align with the all-important Energy Efficiency Design Index.”

Jens Munch – Sales Manager, MAN Alpha Frederikshavn – MAN Energy Solutions said: “In this particular order, we are using our newest technology by fitting the ships with water-lubricated stern tubes. In doing so, we are ensuring that there is no ‘oil-to-water interface’, eliminating any possibility of oil leaks and boosting the owner’s green profile. Such stern tubes are one of the biggest eco-trends that we foresee in the market and we have proven technology available based on our great experience with naval vessels where this solution has been used for many years.”

About German Tanker Shipping

GTS is a Bremen-based shipping company with a fleet consisting of 14 modern oil-product tankers. All built in Germany, nine vessels sail under the German flag and the other five under that of the Seychelles; GTS manages all its own tankers.

Documents

-

PR GTS Xiamen_EN

Contact

Nils Søholt

Trade Press Marine

Group Communications & MarktingMAN Energy SolutionsTeglholmsgade 412450 Copenhagen SVDenmark

nils.soeholt@man-es.com t +45 33 85 26 69Available languages

- DE ·

- EN

Get notified about press releases

Set course to net zero with methanol GenSets - MAN L21/31DF-M

Watch the recording of our MAN ExpertTalk, where we introduced our new engine type: the small-bore four-stroke MAN L21/31DF-M GenSet for methanol operation.

You can look forward to hearing

about this new GenSet type, the Port Fuel Injection (PFI) concept, the fuel gas supply system and the possibility to operate these GenSets on green methanol and biofuel oils.