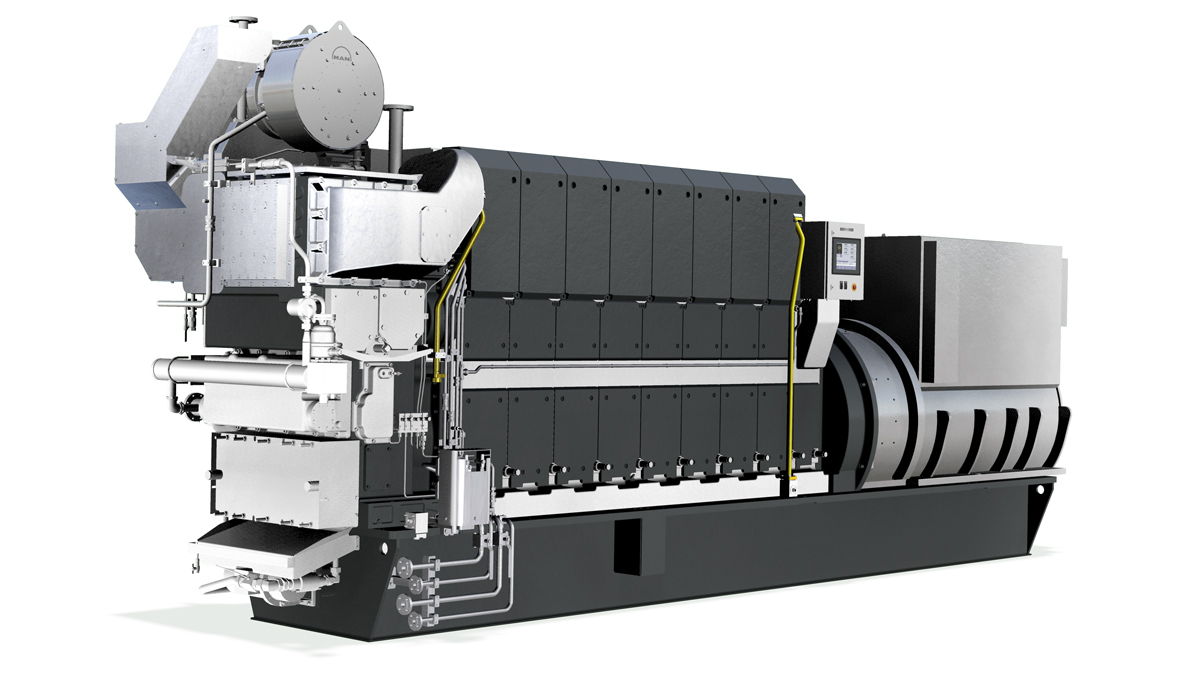

Reduce your carbon footprint with the new MAN L21/31DF-M methanol GenSet

The maritime industry is decarbonizing and methanol is currently one of the leading fuels among the alternative fuel solutions. Following the market demand and rising interest, we hereby introduce the new MAN L21/31DF-M methanol GenSet - the first small-bore dual-fuel methanol GenSet in our portfolio.

MAN Energy Solutions in Frederikshavn, Denmark is home of the MAN L21/31DF-M, our first small-bore GenSet fueled by methanol.

Proven GenSet design

The foundation of this new engine is based on the current L21/31 GenSet and its well-proven technology, which has already accumulated more than 110 million operating hours, with thousands of engines in service.

Key benefits

Perfect design features for efficient and reliable operation

The L21/31DF-M comes with a cost-optimised, low-flashpoint fuel supply system which makes it a competitive solution.

Furthermore, the port fuel injection (PFI) concept provides additional simplicity and an attractive capital outlay. And it is based on proven components.

Long time between overhaul intervals will save you time and costs on engine maintenance and will give you additional flexibility for the planning of your maintenance slots.

Technical specifications

| Description | Main data |

Bore | 210 mm |

| Stroke | 310 mm |

| Speed | 900 / 1,000 rpm (60 Hz / 50 Hz) |

| Output | 1,000 – 1,980 kW |

| Cylinder configurator | 5 – 6 – 7 – 8 – 9 |

| Available fuels | HFO, MDO, MGO, LSFO, ULSFO, Biofuels, MeOH |

| Emission limit | IMO Tier III with SCR after-treatment |

Optimized port fuel injection

The port fuel injection (PFI) system uses a methanol injection nozzle installed outside the combustion chamber. This simplified design removes the risk of blocked nozzles in diesel mode and reduces investment costs thanks to its easy installation and integration with standardized components.

MAN SaCoS control system and cybersecurity

The safety and control system MAN SaCoS supports a fast and reliable data-transfer between the engine and the power management system in the control room by easy cable connection.

The engine control system is attached to the engine and features an intuitive user interface and a colour display in different languages. The electric speed governor enables fast response

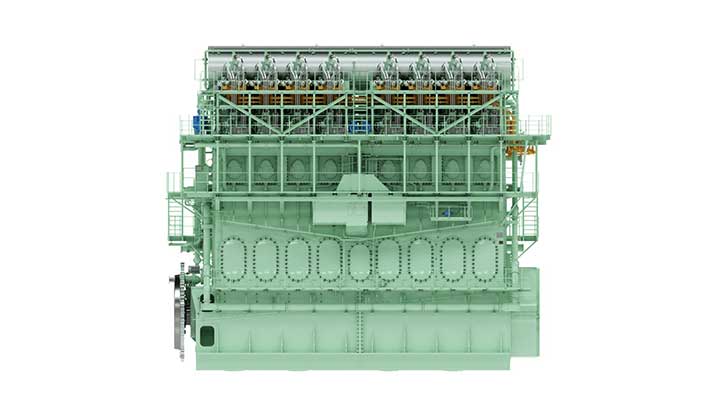

Perfect match for MAN B&W ME-LGIM two-stroke methanol engine

The first MAN B&W ME-LGIM came into service in 2016. Since then, we have accumulated more than half a million running hours on methanol alone, which provides a solid base for new developments. The L21/31DF-M is a perfect match for this methanol-fueled propulsion engine.

Low-pressure fuel supply system

The methanol supply system for L27/38DF-M is a cost-optimised low-pressure system, effectively making it a profitable solution providing a lower capex.

Increased fuel flexibility

The possibility to operate engines on methanol as a drop-in fuel means that e-methanol and bio-methanol increase the fuel flexibility of the new engine and the potential of methanol as an option for GenSet applications on large merchant marine vessels as well as for propulsion solutions for smaller vessel types.

Engine control system: SaCoS

The safety and control system MAN SaCoS supports a fast and reliable data-transfer between the engine and the power management system in the control room by easy cable connection.

The engine control system is attached to the engine and features an intuitive user interface and a colour display in different languages. The electric speed governor enables fast response

What makes the new methanol-fueled MAN L21/31DF-M GenSet special? Watch our 3D engine animation to find out more about the working principles, and also the Port Fuel Injection system.

Service solutions for your equipment

MAN PrimeServ offers a range of modernization solutions for optimizing the reliability, availability, and economic efficiency. MAN’s upgrade and retrofit solutions are tailor-made to customers’ specific applications and equipment.

Are you ready for green methanol?

Newbuild or retrofit? What are the costs? What are the benefits? Take the lead in sustainable shipping by contacting us today!

Continue reading

Inside the making of a methanol GenSet

Related products

-

Alternative fuels

Operate your in service engines with Alternative Fuels: Unleash Carbon-Free & Carbon-Neutral Solutions for MAN, B&W and S.E.M.T. Pielstick engines. Achieve Fuel Flexibility for Existing Systems!

-

MAN B&W ME-LGIM

The MAN B&W ME-LGIM is a two-stroke, dual fuel engine that runs on both methanol and conventional fuels.

Related News

MAN Cryo Wins Approval for Ammonia Fuel-Supply System

MAN Cryo has announced that its design for an ammonia fuel-supply system to safely provide ammonia to marine-engine applications has been awarded an Approval in Principle from classification societies, DNV and Bureau Veritas.

Part of MAN Energy Solutions and a leading expert in the field of storage and handling of LNG and natural gas, MAN Cryo developed the system in cooperation with Chinese company, Yada Green Energy Solutions, with whom the company has previously cooperated to provide equipment for LNG and methanol marine fuels.

Xiang Guangqing, Chairman, Yada Green Energy Solutions, said: “Facing the climate-change issue, no one can solve it alone and we firmly believe that cooperation is a powerful means of achieving this. YADA and MAN Cryo are customer-centric operators, providing high-quality, dual-fuel system solutions and continuously achieving new breakthroughs in handling methanol and ammonia.”

He continued: “Yada Green Energy Solutions has set ambitious goals to accelerate the green transformation of the global-transportation industry. Working together to support global development, understanding and anticipating customer needs is an important driving force for our daily work. MAN Cryo and YADA will unite with industry peers, embrace innovation and cooperation, and jointly move towards the sustainable future of global shipping.”

Henrik Malm, Managing Director, MAN Energy Solutions Sweden said: “We are pleased to announce the successful achievement of a significant strategic milestone for MAN Cryo in cooperation with Yada Green Energy Solutions. This accomplishment underscores our unwavering commitment to our global customer base as we collectively work towards a decarbonised world. The establishment of a secure and reliable fuel-supply system for future ammonia engines marks a pivotal development.”

Malm added: “Ship owners can rest assured that MAN Cryo, in cooperation with Yada Green Energy Solutions, is delivering a market-ready solution adhering to the highest security standards and embodying world-class engineering. Once again, MAN Cryo has demonstrated pioneering leadership in the engineering of fuel-supply systems for emerging fuel solutions. This achievement further solidifies our position as industry innovators, dedicated to advancing cutting-edge solutions in response to the evolving landscape of sustainable energy.”

About YADA

Yada Green Energy Solutions provides customers with one-stop, full lifecycle services including principle design, stress analysis, production design, optimisation design, component manufacturing, pipeline prefabrication, module integration, installation and commissioning, safety monitoring, global operation and maintenance.

About MAN Cryo

MAN Cryo offers system design and engineering solutions for the storage, distribution and handling of liquefied gases and has a pioneering reputation within the marine sector. It supplied the world’s first LNG fuel-gas system for the ‘Glutra’ ferry in Norway in 1999, while in 2013 it supplied the world’s first LNG bunker vessel – the ‘SeaGas’ – with operations in Stockholm, Sweden. More recently, MAN Cryo delivered the first liquid-hydrogen fuel-gas system to be installed below deck aboard a ship.

Contact:Kristoffer Lorentsson – Sales & Project Manager, MAN Cryokristoffer.lorentsson@man-es.com

Documents

-

PR MAN Cryo Yada_EN

Contact

Nils Søholt

Trade Press Marine

Group Communications & MarktingMAN Energy SolutionsTeglholmsgade 412450 Copenhagen SVDenmark

nils.soeholt@man-es.com t +45 33 85 26 69Available languages

- DE ·

- EN

Get notified about press releases

Set course to net zero with methanol GenSets - MAN L21/31DF-M

Watch the recording of our MAN ExpertTalk, where we introduced our new engine type: the small-bore four-stroke MAN L21/31DF-M GenSet for methanol operation.

You can look forward to hearing

about this new GenSet type, the Port Fuel Injection (PFI) concept, the fuel gas supply system and the possibility to operate these GenSets on green methanol and biofuel oils.