The growing need for digital plant management

The global pandemic has made the importance of digital-based remote support clearer than ever. And yet it is only one of the many arguments in favor of comprehensive digital life-cycle management and autonomous operation.

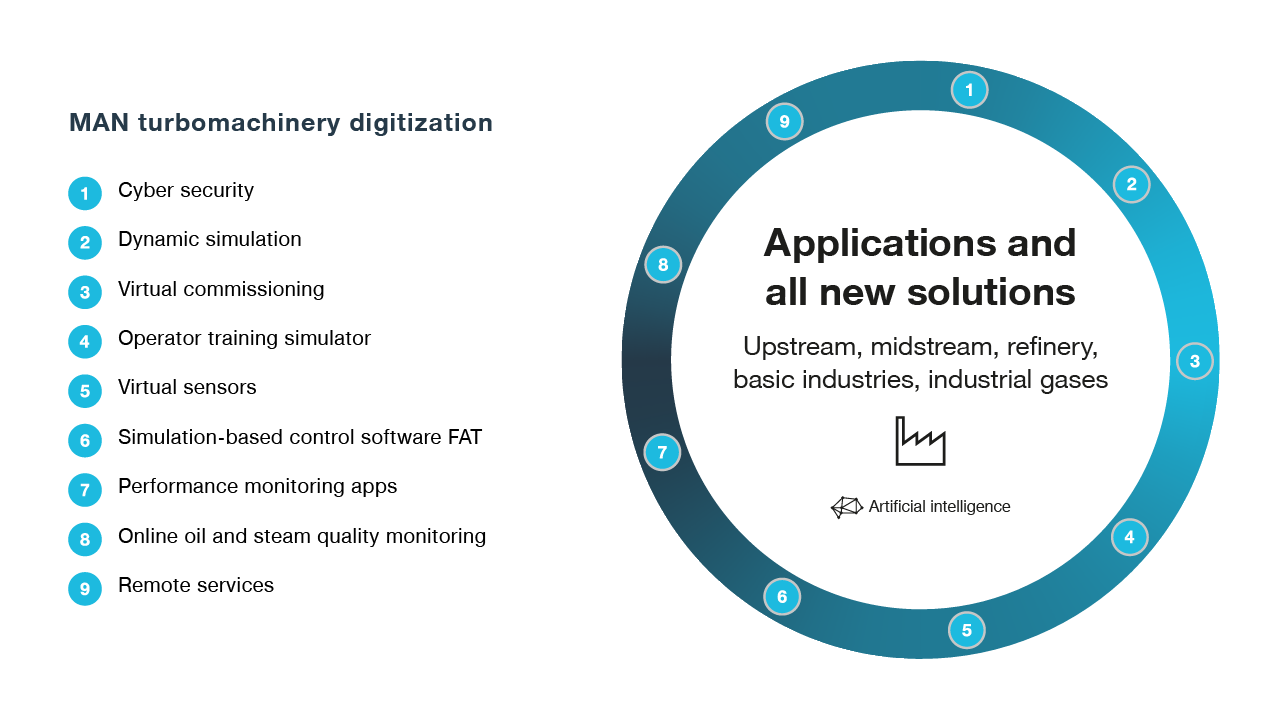

Digitalization

makes highly automated, fully automated, and autonomous operation possible, thereby reducing costs while increasing flexibility and resilience. MAN Energy Solutions provides digital solutions for the whole life cycle of a turbomachinery plant

– from planning and manufacture to commissioning and operation.

Objectives and benefits of autonomous operation

Combining human expertise with artificial intelligence is the key to MAN’s innovative digital solutions. Our main objective is to make sure that resources are produced and used in the most reliable, sustainable, and efficient way.

Specific benefits include:

- Higher energy efficiency

- Reduced duration and cost of inspections

- Lower OPEX

- Increased availability, fewer unplanned shutdowns, and longer uninterrupted operation

- Fewer human errors

- Higher production efficiency

- Reputation enhancement of digitization and decarbonization

- Compliance with international cyber security standards

Find out more in our white paper

Introducing autonomous operation

Superior digital solutions for turbomachinery equipment

Our digital solutions suite spans design, manufacturing, inspection, testing, installation, cold and hot commissioning and remote services for operation. Using our MAN PrimeServ Assist services and MAN CEON digital platform, we offer remote supervision and support in cases where deployment of field service experts to the site is challenging or impossible.

Case Studies

Remote commissioning in Uzbekistan

In 2020, Uzbekistan went into lockdown because of COVID-19, forcing our engineers to return before completing the project. They were working on a four-part compressor train (an air and nitrous oxide compressor, a gas expander, and a steam turbine) for a new nitric acid plant being built for the country’s largest chemical company, JSC Navoiyazot. This forced us to take a historical step in mechanical engineering: The first fully remotely supervised cold and hot commissioning of a compressor train using digital technology. The remote commissioning was made possible by the MAN CEON application, which monitors the compressor train’s operation around the clock, and the PrimeServ EyeTech support tool, an augmented reality app originally introduced by MAN Energy Solutions for remote servicing or to provide technical assistance during troubleshooting.

Remote commissioning in Japan

In 2021, MAN Energy Solutions completed the remote commissioning, cold and hot, of the turbomachinery for a 50 MW biomass power generating plant. The customer was Mitsui E&S, based in Chiba, Japan, and the equipment included a DK050/30 steam turbine, a DG05/50 steam turbine, gear, generator, and auxiliary equipment.

Talk to our Experts

Downloads

Continue reading

-

Ethical hackers

MAN Energy Solutions takes a security-first approach to their products, employing ethical hackers like Felix and Nico Lindner at Recurity Labs to uncover vulnerabilities throughout the development and operation of their products.

-

Learning from machines

The autonomous operation of turbomachinery, assisted by machine learning and remote diagnostics, will boost efficiency and help decarbonization.

-

Energy management for a smart planet

As power systems become more complex, here’s how industries can manage future energy needs.

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.