From unmanned to autonomous operations

Unmanned operation means all plant equipment is controlled remotely and there is no operating crew permanently required on site. It also allows proactive maintenance planning. In full autonomous operation, the management of the machinery is permanently taken over by the control and remote diagnostic tool using advanced analytics with real-time data-based self-diagnostic systems. MAN Energy Solutions is market leader in this area and has made great progress towards autonomy since our subsea compression system at Åsgard field. Since then, MAN Energy Solutions is on the journey to autonomous operations and is getting progressively closer to this goal in all market segments of the industries by 2028.

Reference project: Yggdrasil area

MAN Energy Solutions is delivering compressor technology for the first unmanned gas production platform at the Yggdrasil field development. This game changing next generation operating model, ordered from Aker BP and Aibel, comprises seven compressor units for three offshore gas production platforms in Norway called Munin, Hugin A and Valhall. Munin will be the first gas platform on the Norwegian continental shelf designed from the start for operation without a crew: it will not have a helicopter deck or living quarters and will be remotely operated from an integrated operations center and control room onshore in Stavanger (Norway). MAN digital solutions allow fully-automated operation of the compression technology.

| Project | Yggdrasil field development (three offshore gas production platforms in Norway) |

| Customers | Aker BP and Aibel |

| Scope of supply | Seven compressor units (five HOFIM® compressor units and two RB compressor skids) and digital solutions for unmanned operation |

| Challenge | Deploy two HOFIM® compressors at Munin, the first remotely operated gas production platform, and minimize manning |

| Solution | MAN digital solutions allow fully-automated, semi-autonomous operation of the compression technology, a game changer in the upstream industry |

Key Benefits

Decarbonization

Lower costs

Digital solutions enabling unmanned operation, lower TOTEX and OPEX thanks to reduced manpower and proactive maintenance planning, but especially through the increase in energy efficiency. A small increase of 1% in efficiency can have a large positive effect on operating profits.

Digital solutions enabling unmanned operation, lower TOTEX and OPEX thanks to reduced manpower and proactive maintenance planning, but especially through the increase in energy efficiency. A small increase of 1% in efficiency can have a large positive effect on operating profits.

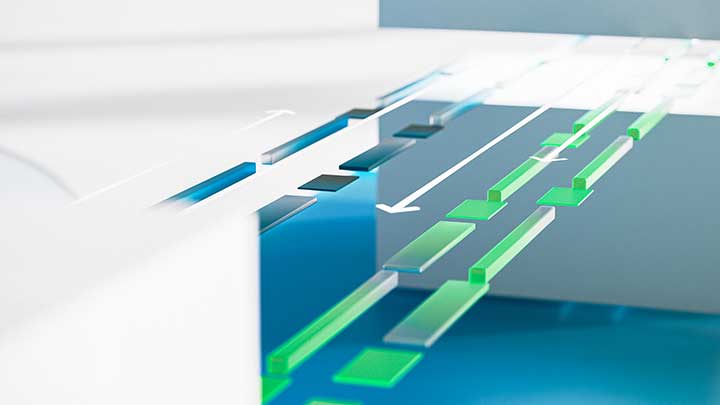

Digitalization

AI tools and digital twins are embedded in our leading digital solutions to enable unmanned operation and prepare the path to autonomous operation. Our online performance-monitoring app provides real-time insights into system performance, allowing for proactive decision-making and optimization. Additionally, virtual sensors allow operators to validate measured data in real time, increasing operational efficiency and accuracy. By leveraging machine learning capabilities, the system also continuously learns and adapts to improve performance over time.

AI tools and digital twins are embedded in our leading digital solutions to enable unmanned operation and prepare the path to autonomous operation. Our online performance-monitoring app provides real-time insights into system performance, allowing for proactive decision-making and optimization. Additionally, virtual sensors allow operators to validate measured data in real time, increasing operational efficiency and accuracy. By leveraging machine learning capabilities, the system also continuously learns and adapts to improve performance over time.

Leading digital expertise

MAN Energy Solutions is leading the way in the digitalization of turbomachinery equipment. In particular, we have mastered the challenges of remote control for subsea activities, as we demonstrated in 2015 when we installed the world’s first remotely operated subsea gas-compression facility at the Åsgard platform 300 meters below sea level.

Safe

Our digital solutions help to make our already safe platforms even safer: AI-based digital modules are bundled into digital convoy packages and provide full lifecycle support to ensure safe, reliable, efficient and unmanned field operations 24/7. This means that no employees are exposed to any risks.

Unmanned

Offshore operations are challenging and costly. MAN digital tools for unmanned operation reduce costs and give you full control from afar. Digitalization of processes prevents human errors and reduces production failures. Our unmanned systems prepare the path to autonomous operation.

Availability

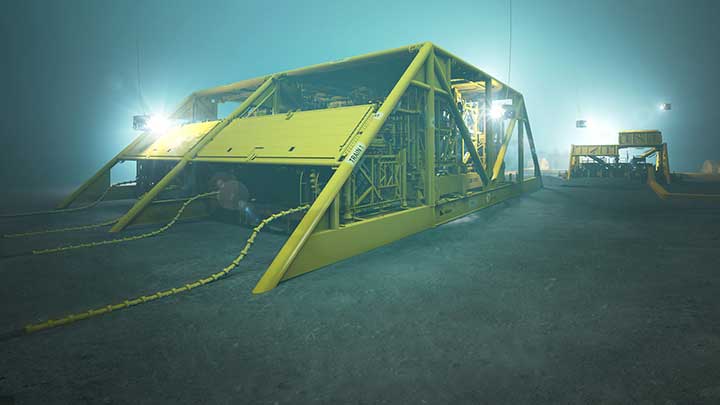

MAN digital solutions increase the reliability and availability of the plants. Proactive maintenance planning results in minimal downtime and maximum productivity through predictive and prescriptive maintenance. The Åsgard compressors have been remotely controlled since 2015 with 99.9% availability and 120,000 accumulated running hours.

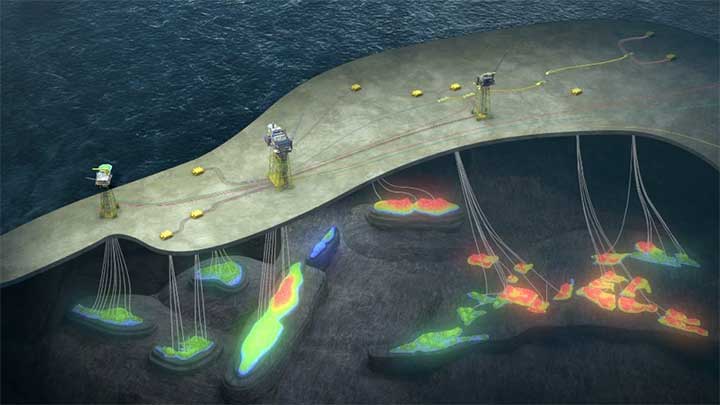

World first: Åsgard subsea gas compressor station

In 2015, MAN Energy Solutions partnered with Aker Solutions to install the world’s first subsea compression system at Equinor’s Åsgard field, 300 m below sea level, off the coast of Norway. Conventional extraction methods face the problem of sinking gas pressure when a field is partially depleted. The MAN HOFIM® compressors keep the gas flowing. Putting the compression system on the seabed near the wellheads improves recovery rates and reduces capital and operating costs. Moreover, it has essential advantages in the form of improved safety for our employees and a significant reduction of the carbon footprint. The compressor units are helping to extend the gas field’s productive life by 15 years. The Equinor & MAN team received the UTF (Underwater Technology Foundation) Subsea Award in 2017. In December 2017, MAN Energy Solutions won the Platts Global Energy Award in the “Commercial Application of the Year” category.

| Project | World’s first subsea gas-compression facility at the Åsgard offshore gas field. |

| Customer | Equinor |

| Scope of supply | Two HOFIM® compressor units and the digital solutions for unmanned operation. |

| Challenge | Develop a solution that can resist conditions 300 m below sea level and be remotely controlled. |

| Solution | The MAN digital solution allow fully-automated operation of the compression technology, with more than 120,000 accumulated running hours without intervention and an availability of close to 100%. |

Talk to our experts

Ready for autonomous operation?

We combine human expertise with artificial intelligence to provide you with clear digital strategies for autonomous operation and to achieve our goal of fully autonomous operations in all market segments of the industries by 2028.

Continue reading

Explore more topics

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.