Chemicals – a refined material in high demand

The chemical industry has been shaping our lives for a long time – this is very unlikely to change any time soon. In fact, chemicals reach every aspect of our existence. Technological innovation from MAN Energy Solutions makes the industry more sustainable and profitable.

Supplying chemicals to the world

Environmental and economic considerations are shaping the industry

Countless industries work with a long list of chemicals. These are used in the production of resins or paints, of hormones, pharmaceuticals, fertilizers or other products.

Global demand for these products is rising constantly. On top of this rise in demand, these industries face an increasing necessity to control energy costs and to improve their environmental footprint. Squaring this circle is difficult - technological innovation is the only way to go. Cutting waste, reducing production costs, using larger reactors, re-using energy and by-products: there are many options to go for a more efficient future.

Equipment you can rely on

For the production of dozens of different chemical compounds, MAN Energy Solutions tubular reactor technology is a crucial component. Our customers rely on our equipment for their profitable, efficient and safe production of chemicals.

CCUS

Chemical plants produce large amounts of CO2 emissions. The CO2 in flue gases can be captured using methods such as amine treatment or cryogenic capture. After purifying, the CO2 can be compressed and transported to be used as a feedstock for synthetic fuels, beverages, dry ice, or chemicals. CO2 can also be stored permanently in secure underground reservoirs. MAN Energy Solutions supplies the technology for CO2 compression and liquefaction, as well as for heat recovery and integration in your plant.

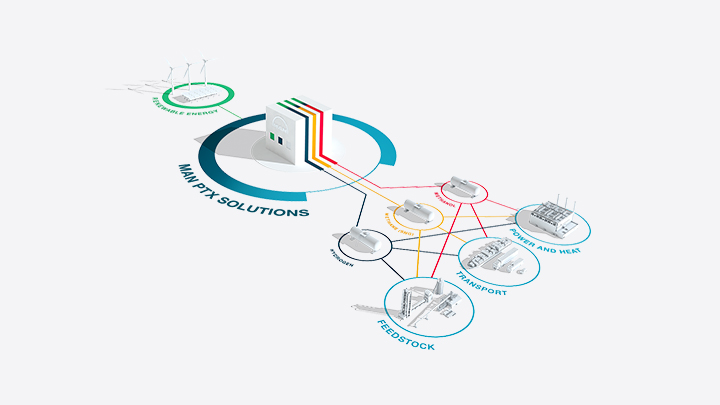

More on carbon capturePower-to-X (PtX)

PtX processes include:

PtX processes include:

- Power-to-Gas (PtG)

- Power-to-Liquid (PtL)

PtX processes are used for the production of:

- E-methanol (CH3OH)

- Synthetic fuels

- Synthetic natural gas (SNG), renewable methane

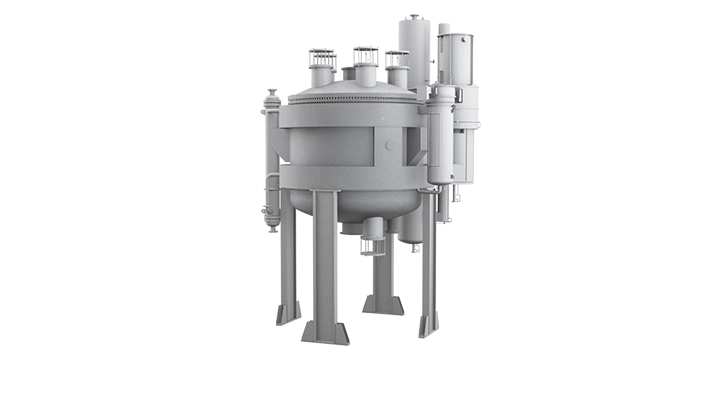

DWE reactors

MAN DWE reactors are used to make many kinds of chemical compounds, e.g. phthalic and maleic anhydride, methyl methacrylate, acrylic acid, and acrolein. We offer salt-operated and water-/oil-/gas- operated reactors incorporating up to 60,000 tubes, up to 10 m in diameter and 1,800 metric tons in weight. We also make customized reactors for rare and unusual processes. Our custom-made reactors are up to 60 m long and have an operating temperature of up to 550 °C.

More on DWE reactorsHeat pumps

Heat pumps offer the chemical industry a simple way to reduce heating costs and CO2 emissions. A heat pump extracts heat from a low temperature source like water or, better still, waste heat from machinery and amplifies it to a useful high temperature. If powered by renewable electricity, the heat pump supplies carbon-neutral heating or cooling. We scale our heat pump solutions to your temperature and power needs.

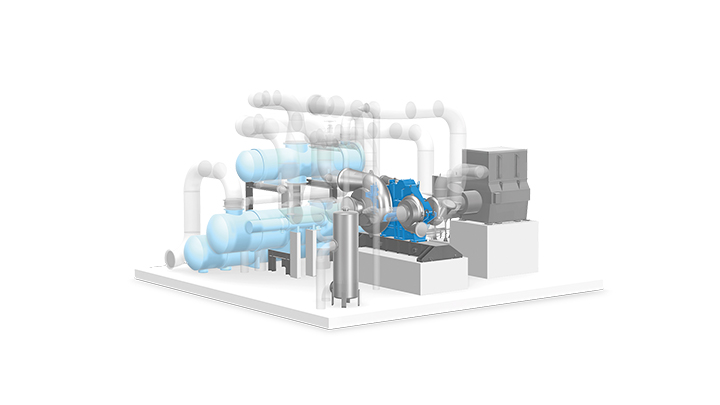

More on heat pumpsCompression equipment

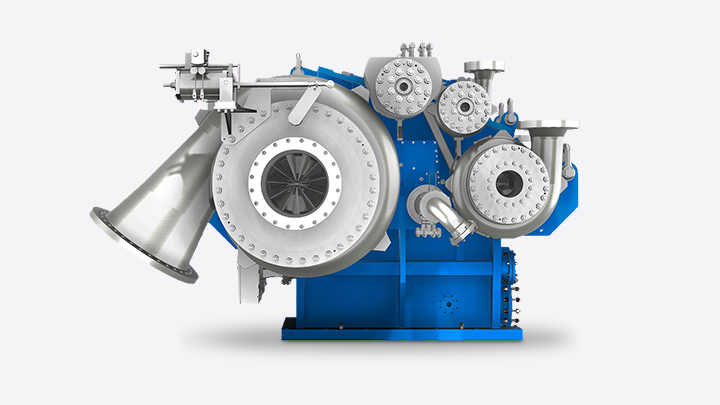

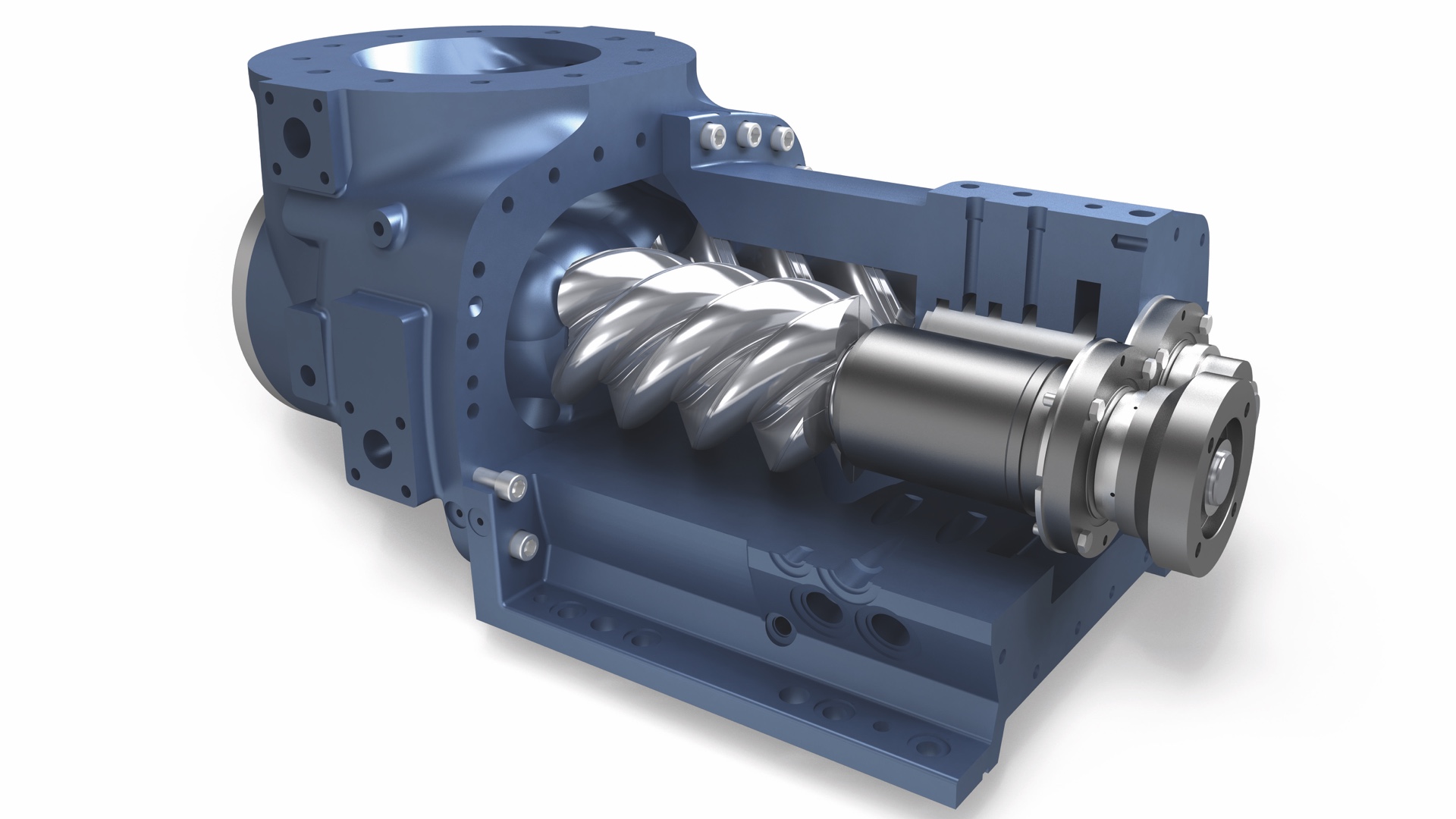

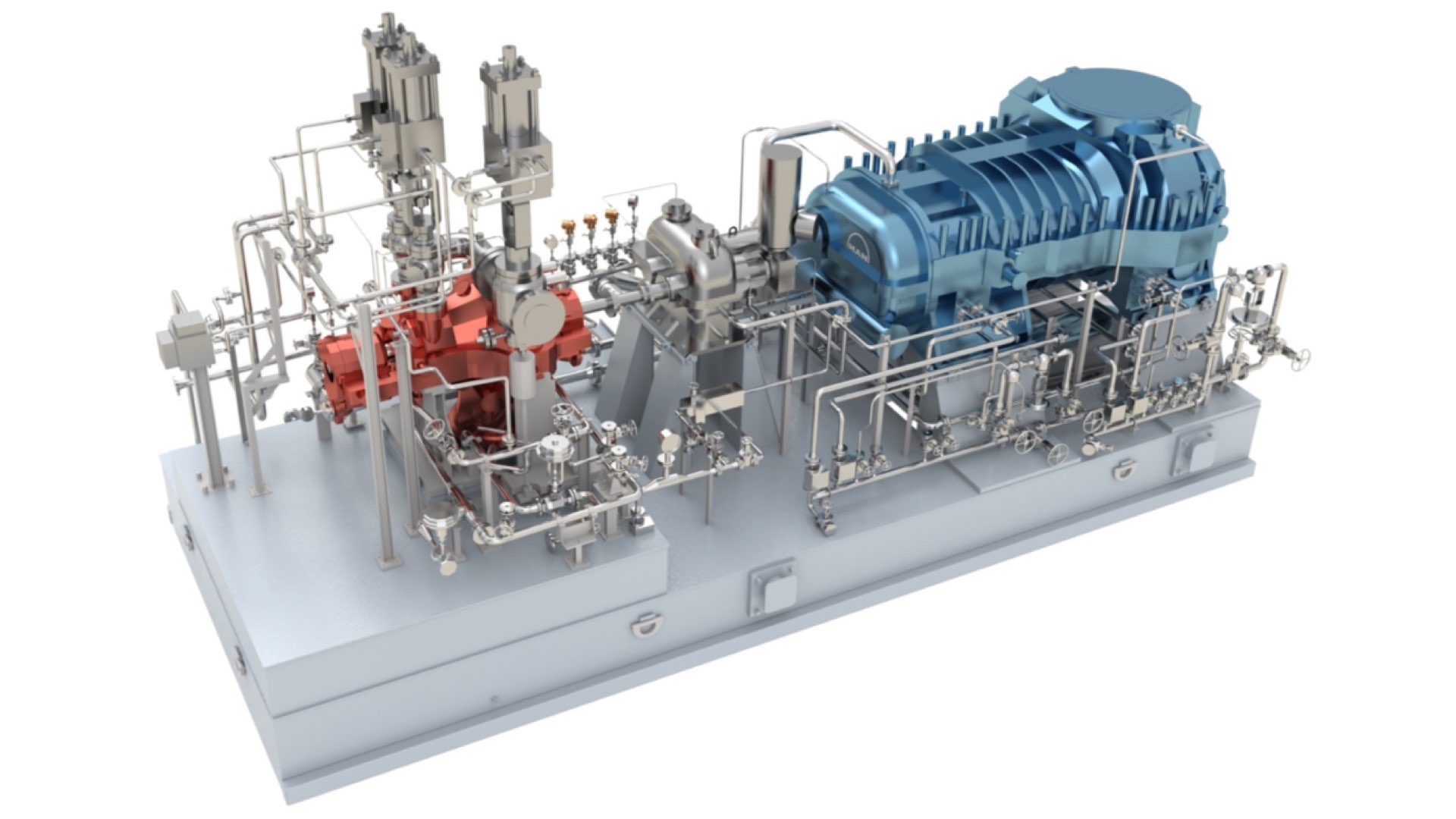

Our oil-free process gas screw compressor runs without oil injection. This eliminates the threat of a contaminated end product. Our compressors are extremely reliable, need minimal maintenance, ensure reduced downtime and have been trusted pieces of machinery all over the globe for many decades.

Our oil-free process gas screw compressor runs without oil injection. This eliminates the threat of a contaminated end product. Our compressors are extremely reliable, need minimal maintenance, ensure reduced downtime and have been trusted pieces of machinery all over the globe for many decades.

Also very popular in the chemical industry are our range of centrifugal compressors. We offer both vertically split “barrel-type” (RB) and horizontally split (RH) designs. Our centrifugal compressors have a pre-designed sealing system for easy assembly. They offer high availability and require very little maintenance.

Go to compressors for the process industryDeveloping your process – Bridging laboratory research to commercial reactors

Your R&D is the starting point for new products or catalyst developments. To minimize your exposure, we run pilot reactor tests in our technical center. These deliver the data required for an eventual scale-up and bridge the path to production in large reactors.

Equally, should the conditions of your process have changed – such as using a new catalyst, different feed or higher throughput – you can use our service of pilot plant tests in order to optimize your evolved process.

Our screw compressors at work in the chemical industry

Styrene monomer production

This vacuum compressor features a high pressure ratio. A water injection technique allows for the production of high pressure using a single-stage compressor. This also prevents polymerization. As molecular weight of the gas is relatively low MAN Energy Solutions screw compressors serving as positive displacement compressors are the optimum choice for this application.

| Country | China |

| Year completed | 2017 |

| Duty | Vacuum compressor |

| Type | 2x screw compressors type SKUEL816 |

| Scope | 1x vacuum compressor |

| Driver | Steam turbine |

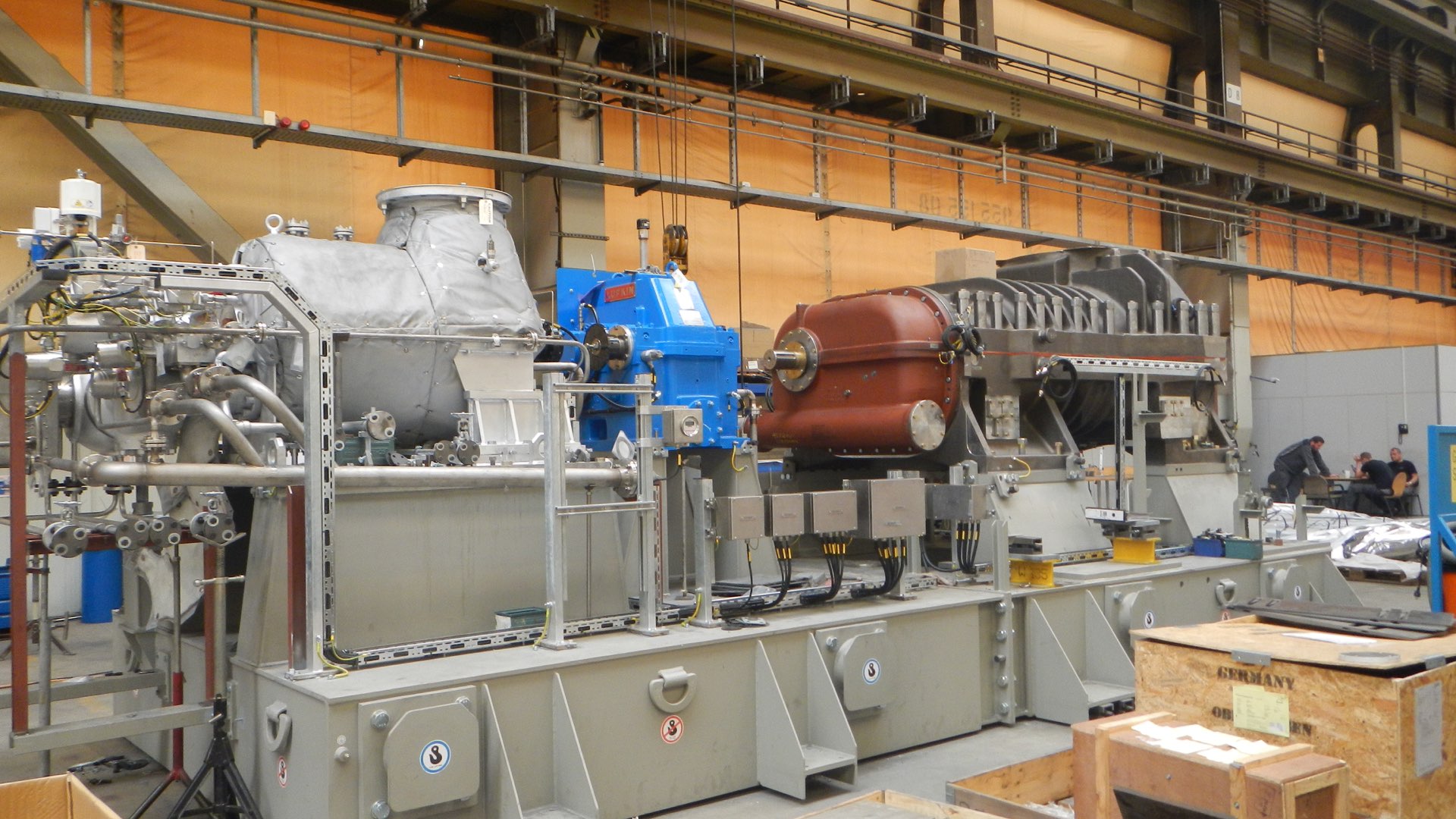

Soda ash plant

By going for size, the customer reduced costs (one compressor instead of two) and increased production volume. In fact, this is the largest screw compressor for a soda ash plant ever delivered. The extreme reliability of the product allows for overall cost reduction.

| Country | India |

| Customer | Nirma, one of India’s leading manufacturers of soaps and detergents |

| Year completed | 2016 |

| Scope | 1x steam turbine driven screw compressor, SKUEL816 |

MAN Heat pumps for industrial processes

Take part in our MAN ExpertTalks and find out how broad our product portfolio of heat pumps for industrial processes is, in which projects MAN heat pumps are already being used and get the latest market insights from our experts. We look forward to your participation!

Downloads

Contact our experts

Are you producing chemicals? Are you looking for cutting-edge equipment?

Whatever chemical you are working with, our tubular reactors and special compressors will not let you down. Find out how we can support your production process.

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.