Leveraging key technologies to achieve sustainability

We have always considered challenges within the larger context. Today, this means acknowledging that no one single solution or technology can get us towards our goal of net zero emissions. This is why we have selected and developed five key technologies which make up the center pillars of our decarbonization strategy, complementing our existing and always evolving core portfolio.

These technologies are able to reduce emissions in hard-to-abate sectors such as shipping, power and heat generation, industrial processes such as cement and chemicals, which are energy-intensive and hard to electrify. Green engines, solutions for carbon capture, utilization and storage (CCUS), as well as innovative industrial-scale heat pumps, cost-effective electrolyzers for green hydrogen production and retrofitting solutions – all of these technologies give us the leverage to decarbonize industries as quickly as possible.

Our five core technologies have immense leverage to reduce so called hard to abate CO2 emissions. This means we have the lever to address 30% of global emissions.

Key transitional technologies

The following figures are examples of the benefits of MAN Energy Solutions’ solutions

5 key future technologies

We offer a portfolio of pioneering future technologies that help fight climate change while presenting significant market potential and business success. With our know-how, expertise and leading edge in each of these technologies, we are well-equipped to provide sustainable solutions to the current climate challenges.

We retrofit ships and plants to reduce fuel consumption and emissions.

Our green engines powered by future fuels such as green hydrogen, ammonia, methanol, and biofuels, are essential for long-term decarbonization.

We are also working with partners on CCUS (carbon capture, utilization, and storage) to capture and store unavoidable carbon dioxide emissions.

Lastly, our heat pumps are an energy-efficient solution for heating and cooling buildings by reducing energy demands.

Related news

-

Monday, December 16, 2024

Europe’s Largest Fluvial Heat-Pump Bound for Cologne District Heating

RheinEnergie to cut ~100,000 tons of CO2 annually with MAN heat-pump technology in Cologne; 150 MW facility to become Europe’s largest heat-pump installation, harnessing thermal energy from Rhine for climate-neutral heating -

Tuesday, December 10, 2024

MAN Energy Solutions and Vicinity Unite to Decarbonize Boston with Landmark Heat Pump Project

Pioneering project to establish a 35 MW industrial-scale steam heat pump to reduce emissions of district energy network – role model for other US cities -

Monday, December 9, 2024

World’s First VLCV Methanol Retrofit Represents Blueprint for Future Projects

Successful engine-retrofit of Very Large Container Vessel ‘Maersk Halifax’ to dual-fuel ME-LGIM unit -

Tuesday, December 3, 2024

Full-Scale Ammonia Engine Opens New Chapter

Two-stroke engine testing in Copenhagen marks important milestone on path to dual-fuel ME-LGIA development

Related articles

-

Retrofitting engines for greener fuels

Retrofitting engines for greener fuels is a “no regret” move in the maritime energy transition.

-

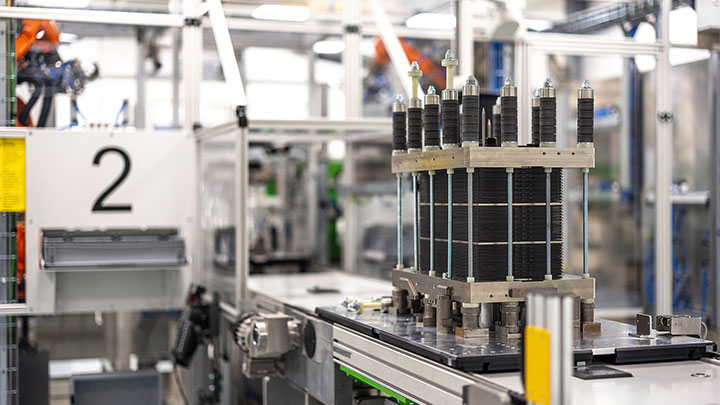

Opening Quest One hydrogen Gigahub

Quest One opens new Gigahub factory in Hamburg, Germany, for the serial and automated production of electrolysis stacks.

-

Lifecycle Upgrade Grand Cayman

MAN PrimeServ is turning 25-year-old engines into highly efficient modern types at a power plant on the Cayman Islands. Learn more about our Lifecycle Upgrades.