Once a time-consuming process, robots and automation at Quest One’s new Gigahub speed up PEM stacks production.

It’s being hailed as the most modern production facility in Europe. Using automotive industry methods to bring automated series production for PEM stacks, Quest One’s new Gigahub factory has kicked off a new phase of the green hydrogen economy.

By Moritz Gathmann

Here on the outskirts of Hamburg, Germany, on this bright early autumn day, the spirit of optimism is practically tangible. The hall of Quest One’s new Gigahub factory is packed with hundreds of guests – including German Federal Chancellor Olaf Scholz – celebrating its opening as a milestone in the EU’s green hydrogen economy.

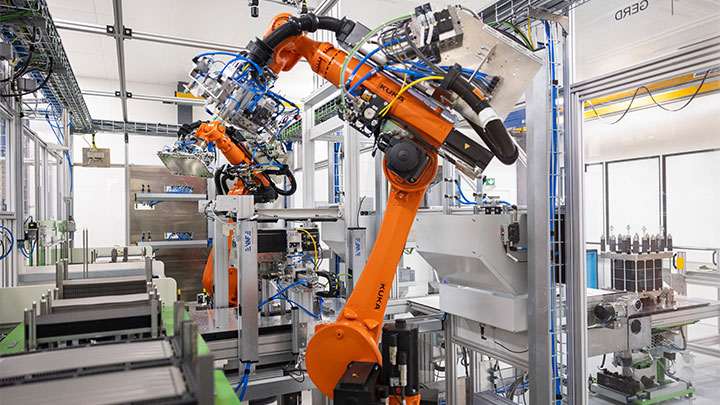

The factory hall is buzzing with talk, while behind a glassed-off assembly line in the middle of the hall the reason for all this optimism is quietly taking place – and it is impressive: Robot arms quickly swivel and handle with precision as they automatically work to build PEM (Proton exchange membrane) stacks.

Building stacks 75 percent faster

These stacks are the technological heart of Quest One’s electrolyzers, splitting water with the help of renewable electricity into oxygen and hydrogen, and allowing large amounts of green hydrogen to be produced in a short time. Previously the stacks had been largely handmade, a time-consuming task, but now with the Gigahub’s new serial production line and its increased automatization, the time for building a 70-cell PEM stack is cut by 75 percent.

We’ve automated cell stacking and produce with an accuracy in the micrometer range.

It takes less than an hour to build these stacks, a new benchmark in production, and speed is what’s needed to ramp up Europe’s green hydrogen capacity. Green hydrogen, which is carbon-free, can decarbonize hard-to-abate industries that require hydrogen as a feedstock, like steel, plastics and fertilizer production, or use climate-neutral hydrogen-based fuels, like aviation and maritime shipping. Moreover, it can store surplus renewable energy and makes it easy to transport around the world, especially when converted to methanol or ammonia.

Ramping-up the EU’s hydrogen economy

The EU has set a goal of producing 10 million tonnes of green hydrogen and importing another 10 million tonnes by 2030. To help reach those goals, the installed electrolysis capacity in Germany is set to be expanded to 10 gigawatts by 2030, and Germany’s government is promoting the construction of large electrolyzer plants along with essential infrastructure. Chancellor Scholz praised Quest One’s efforts at the opening of the factory, calling it a “real milestone for the rapid ramp-up of the hydrogen economy.

We are a worldwide leader in PEM electrolysis.

Quest One MHP: modular, skid-mounted and ready to install

The “One” in the company’s name stands for its ambitious goal to account for the reduction of 1 percent of the world’s greenhouse emissions by 2050. Today, Quest One, formerly known as H-TEC SYSTEMS, has sold over 50 electrolysis units for the production of green hydrogen with a capacity of up to 1 megawatt each.

“We are a worldwide leader in this segment,” says Robin von Plettenberg, Chief Executive Officer of Quest One, “with a high repeat customer rate.” According to von Plettenberg, the next step to reach their goal is to build large-scale electrolyzers. “Our Modular Hydrogen Platform (MHP) is a scalable system. The electrolyzer consists of standardized blocks with a capacity of 10 megawatts each that can be combined to systems with a capacity of 100 megawatts or more.”

For now, the stacks at the Gigahub are produced in two different production lines: “Titan” is a linear transport system, and “Gerd” is operated with swivel-arm robots. Both names derive from Saturn’s two moons, where the atmosphere consists of 95 percent hydrogen. “The next production line will have only one technology,” says Meister, explaining that this first production period will help determine which line fits best.

But one thing is sure: Quest One is convinced of the advantages of using proton exchange membrane-technology for its electrolyzer stacks. The technology is especially well-suited to produce green hydrogen with renewable electricity. It produces high-purity hydrogen that can be used directly for refueling and it does not require aggressive chemicals.

We invest, we move forward. We are ready to support the road to a hydrogen economy.

The road to 5-gigawatt production facilities

Along with production, research, development and testing of the stacks is being done at the Gigahub factory in Hamburg. The final assembly of the electrolyzer units then takes place in Augsburg and – since the start of this year – Houston, Texas. One gigawatt of green hydrogen capacity can be produced per year at the Quest One Gigahub with the current S450 stack. But the Gigahub has future potential to increase stack production to 5 gigawatts per year over the next few years.

For Jürgen Klöpffer, Member of the Executive Board of MAN Energy Solutions, the investment is “not without risk”, explaining: “Nobody knows how the renewables market will actually look like in 10 or 15 years.” But the investment is very much connected to the future strategy of MAN Energy Solutions making green hydrogen one of five core technologies the company will focus on in the future and expects a huge market potential as well as a huge lever to combat climate-change. That’s why Klöpffer calls the investment a clear statement from MAN Energy Solutions: “We invest, we move forward. We are ready to support the road to a hydrogen economy.”

About the author

Berlin-based journalist Moritz Gathmann’s work has appeared in a number of media outlets, including Der Spiegel, the Frankfurter Allgemeine Sonntagszeitung and Zeit online.

Quest One: Leading hydrogen technology

Quest One (former H-TEC SYSTEMS) is a global leader in the field of PEM electrolysis. The company develops and produces innovative electrolyzers and electrolysis stacks for the economical, efficient and reliable production of green hydrogen. Quest One's declared goal is to make a significant contribution to the fight against climate change with its own products. The company's mission is to avoid one percent of global greenhouse gas emissions by 2050 through the use of its electrolyzers. Quest One is a subsidiary of MAN Energy Solutions.

Explore more topics

-

Hoegh - LNG-powered car carrier

With its first LNG-powered car carrier, Höegh Autoliners is taking a big step towards its target of net-zero by 2040. The centerpiece of the vessel is a MAN Energy Solutions MAN B&W ME-GI dual-fuel engine.

-

Maersk Halifax Retrofit

The world’s first methanol retrofit of the Very Large Container Vessel Maersk Halifax opens the doors for green fuels.

-

Methanol dual fuel retrofit

Engineers are now testing a retrofit for four-stroke ship engines that will enable ferry and cruise ship operators to meet the growing requirements on emission reduction with green methanol.

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.