Engine upgrades are increasing efficiency and preparing the power supply on the Cayman Islands for dual fuel operation.

In order to supply more cost-efficient energy for residents, tourists and businesses, the Caribbean Utilities Company, Ltd. (“CUC”) is giving five of its MAN engines a Lifecycle Upgrade (LCU): 25-year-old engines are turned into highly efficient modern types, a first step to prepare them for a later upgrade to dual fuel operation.

By Roman Elsener

As the plane descends on Grand Cayman, the small island in the middle of the Caribbean presents itself from its most idyllic side: The surf is gently lapping the sandy beaches, a breeze is mitigating the heat and clear turquoise waters invite for a swim.

The island, known for its diverse sea life and the powerful financial sector, attracts hundreds of thousands of tourists and businesspeople from around the world. They, as well as the roughly 81,000 inhabitants of Grand Cayman, depend on the Caribbean Utilities Company, Ltd. (“CUC”) to provide electricity to more than 33,000 households and businesses including high-class hotels, banking institutions, and their international airport.

CUC's power system (not including distributed generation resources) is comprised of 20 generating units (17 diesel engines, two combustion turbines, and one steam turbine that works off the excess heat from the generating units) with a combined capacity of 165.55 megawatts (MW) with the majority of electricity generation from the company’s seven MAN engines.

The engines were installed at the turn of the millennium and have served the Company most reliably – despite the fierce storms and hurricanes that can plague the islands. But in a quarter of a century there has been a lot of technological progress, and a general desire for more efficient and cleaner generating solutions.

This is one of the reasons why CUC has decided to give the MAN engines a thorough upgrade. “By performing this lifecycle upgrade on our engines, we can enhance the existing engines without needing additional infrastructure. This approach results in significant cost savings for our customers and enables our company to continue utilizing the engines efficiently,” says Sacha Tibbetts, CUC’s Vice President of Customer Services and Technology.

Upgrading to a modern engine type

With the release of the new National Energy Policy (“NEP”) by the Cayman Islands Government, CUC understands the critical role that it plays in allowing the country to meet the renewable energy penetration and carbon emission goals. The NEP has set ambitious goals for the country to reach a 30% reduction in emissions over the 2019 levels by 2030, 70% renewable energy penetration by 2037, and 100% emissions reduction and renewable penetration by 2045.

The LCU upgrade will assist with meeting the interim targets as the upgrades will begin the transition for the engines to run on natural gas. “This upgrade offers efficiency benefits, along with the potential for dual fuel functionality in the future,” says Sacha Tibbetts. The Company is currently evaluating the viability of liquefied natural gas as a transitional fuel, and this upgrade will lay the foundation for the transition to LNG. “LNG would lead to significantly less CO2 emissions when compared to diesel and will allow for cost savings to our customers,” – Sacha Tibbetts

In this LCU, three MAN 12V48/60A and two MAN 14V48/60B engines will be converted to modern MAN 51/60 types with a total capacity of 64 megawatts. Completion of the retrofit will bring the five engines, which have already been in operation for more than 80,000 hours, up to the technical standard of a newbuild MAN 51/60.

How to upgrade an engine

Keith Whyte, Senior Project Manager at CUC, is overseeing the Lifecycle Upgrade Project. “We are bringing down the five MAN engines in the engine room and will upgrade them, one after the other. In addition to that we are upgrading the auxiliary systems that support each engine, including the digital control systems,” Keith Whyte explains. The whole LCU per engine, from when the engine is stopped until it is commissioned, performance tested and running again, takes about two months.

We are bringing down the five MAN engines in the engine room and will upgrade them, one after the other

It is steaming hot in the cathedral size engine room. Thomas Sinz, Superintendent at MAN Energy Solutions, and an engineer with decades of experience with ship engines and power plants, is leading the 15 people strong crew from MAN PrimeServ on location – with ten service engineers coming from the PrimeServ hub in Fort Lauderdale, Florida, US. They work six days a week in shifts, seemingly unfazed by the heat and the incessant noise of the engines that are not currently being retrofitted and running at full power.

Thomas Sinz and his crew are in the course of putting the finishing touches on the second overhauled engine, fitting in the last vital part of the exhaust pipe. “With this conversion, the customer basically gets a new engine. In other words, this is not about maintenance, this is about a thorough retrofit so that only the frame, the crankshaft and the gears remain from the previous model. Everything else is new,” says Thomas Sinz.

Future-proofing the engines

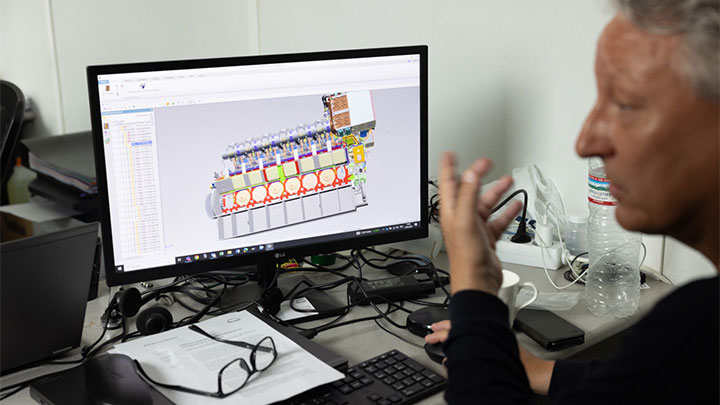

At the outset of such an LCU, more than 200 wooden boxes with hundreds of new engine parts are shipped to the power plant. “In terms of logistics, it's very extensive,” Thomas Sinz says, showing a digital model of the engine on the computer in his makeshift office in a container near the engine room.

“Especially in this day and age, when everything is preparing to become climate-neutral, we have an incredibly successful concept with which an operator can prepare for the future, and we can show them in the digital space how all is done before the first turn of a screw.”

He points out that big shipping companies, cruise ships and other power plants now also rely on such lifecycle upgrades of their engines. Thomas Sinz has recently been on crews on various islands. His experience: “Everyone says: we want that too, because it makes sense in terms of the figures.”

Predicting exactly how much fuel will be saved is difficult, as it depends on many factors: What fuel are you running? What climate are you in, how many pumps are connected? How do you calculate efficiency?

“What we can tell our customers: last year we rebuilt an engine in the Dominican Republic that runs 6,000 hours a year, basically almost all year round. After the conversion, they save 500 tons of fuel a year which reduces the carbon footprint of the engine by roughly 5%,” says Thomas Sinz.

“That's an impressive figure, and on top of that, you save 25 tons of lubricating oil. If you extrapolate that, the investment made will be completely amortized in less than three years, plus you have a new engine that will last for a long time, if you take good care of it,” Thomas Sinz adds.

Preparing for climate-neutral fuels

Besides the large savings on fuel and on lubricating oil, the lower emissions and the higher engine reliability, the main benefit of an LCU is the engine’s readiness for future developments using eco-friendly fuels. “We have made all the preparations to ensure that a conversion to, for example, natural gas can be carried out easily, as soon as CUC is ready," Thomas Sinz says. “We have already drilled the holes that will be needed”.

This kind of thinking ahead by CUC and the consistency of the service that MAN Energy Solutions bring to the project, will allow for energy efficiency, cost savings and cleaner energy to be delivered. “MAN Energy Solutions has been a long term partner with CUC providing engines and related services over the last 25 years. We were happy to embark on this project with a view to creating win-win outcomes for all involved,” says Sacha Tibbetts. “The LCU process has progressed smoothly, with two engines already completed and the third expected to be finished by the end of the year.”

About the author

Roman Elsener is a Foreign Correspondent for the Swiss News Agency Keystone-SDA, specalizing in energy, health and global politics. He shares his time between New York and Switzerland

Lifecycle upgrades

Lifecycle Upgrade is a retrofit solution by MAN PrimeServ that allows ship owners and operators to renew their MAN 48/60 engines and upgrade them to new MAN 51/60 engines. It includes the replacement of many components as well as upgrades to meet the latest regulations.

Explore more topics

-

Hoegh - LNG-powered car carrier

With its first LNG-powered car carrier, Höegh Autoliners is taking a big step towards its target of net-zero by 2040. The centerpiece of the vessel is a MAN Energy Solutions MAN B&W ME-GI dual-fuel engine.

-

Maersk Halifax Retrofit

The world’s first methanol retrofit of the Very Large Container Vessel Maersk Halifax opens the doors for green fuels.

-

Methanol dual fuel retrofit

Engineers are now testing a retrofit for four-stroke ship engines that will enable ferry and cruise ship operators to meet the growing requirements on emission reduction with green methanol.

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.