High performance for rising demand

The global demand for products refined from crude oil is rising. Refinery processes are a critical part of the modern economy. As an industry involving the use of fossil fuels, operators are facing increasing environmental and economic pressures. The right investment decision can steel your business for a challenging market.

Clean high-end fuels and light hydrocarbons production

Refineries process crude oil into clean, high-energy content fuels and light hydrocarbons. In petrochemical plants, these are used as building blocks in the production of a wide range of polymers, paints, glues and materials used in modern products and appliances.

Crude oil composition is variable. Heavy crudes with long hydrocarbon molecules require splitting into lighter fuels in fluid catalytic cracking reactors (FCC). Sour crudes contain corrosive sulfur that is removed in hydrotreaters. The same process can remove nitrogen and aromatics. Hydrocracking units are used by many refineries to adjust the proportion of fuels to petrochemical feedstock. Our machinery is also used for alkylation units or delayed coking plants.

To meet environmental regulations relating to these processes and to increase profitability, refinery operators look towards CO2 capture and compression in order to reduce their CO2 footprint. MAN Energy Solutions machinery trains cover both bases for our customers.

MAN Energy Solutions: Over 100 years of experience in machinery trains for refinery processes

The machinery train sitting at the heart of your refining operations is the one piece of technology your business success revolves around. Make sure you are well equipped.

Customers in the refinery industry find a perfect portfolio of high-quality, proven components in our product offering. You can choose individual components or order an entire, custom-made train. All our trains are equipped with one of our ultra-reliable electric motor or turbine propulsion systems to drive your compressors.

Our short delivery times and low-maintenance machinery allow you to calculate your budget closely. Whichever route you go down, our equipment allows you to optimise revenues by adjusting the output of various clean fuels and petrochemical raw materials.Proven technology for refineries

RFCC/FCC units and turnarounds

MAN Energy Solutions takes global pole position when it comes to apparatus-related solutions for refineries. We are experts for turnarounds, having executed over 100 globally with minimal downtimes. We work as a supplier of individual components but also act as a one-stop-shop for all your requirements, from engineering to site installation.

Go to RFCC / FCC units and turnaroundsHigh-pressure vessels

Our high-pressure vessels weighing up to 1500 mt are shipped directly from our workshop situated on the river Danube. Our highly experienced master craftsmen are in charge of each production step such as welding, rolling or weld overlay. Their dedication and the high-grade materials we exclusively use are reflected in the durability of our products.

Go to high-pressure vesselsRFCC/FCC components

We offer all components for FCC units from main parts (reactors and regenerators) to corresponding internals such as risers and air grids. We also supply other FCC-relevant equipment such as orifice chambers and piping. All components are fully equipped and ready for operation.

In addition to prefabrication, we also offer custom turnaround solutions as a unit contractor: From shutdown engineering to delivery and assembly – all aligned with our customers’ specific on-site requirements.

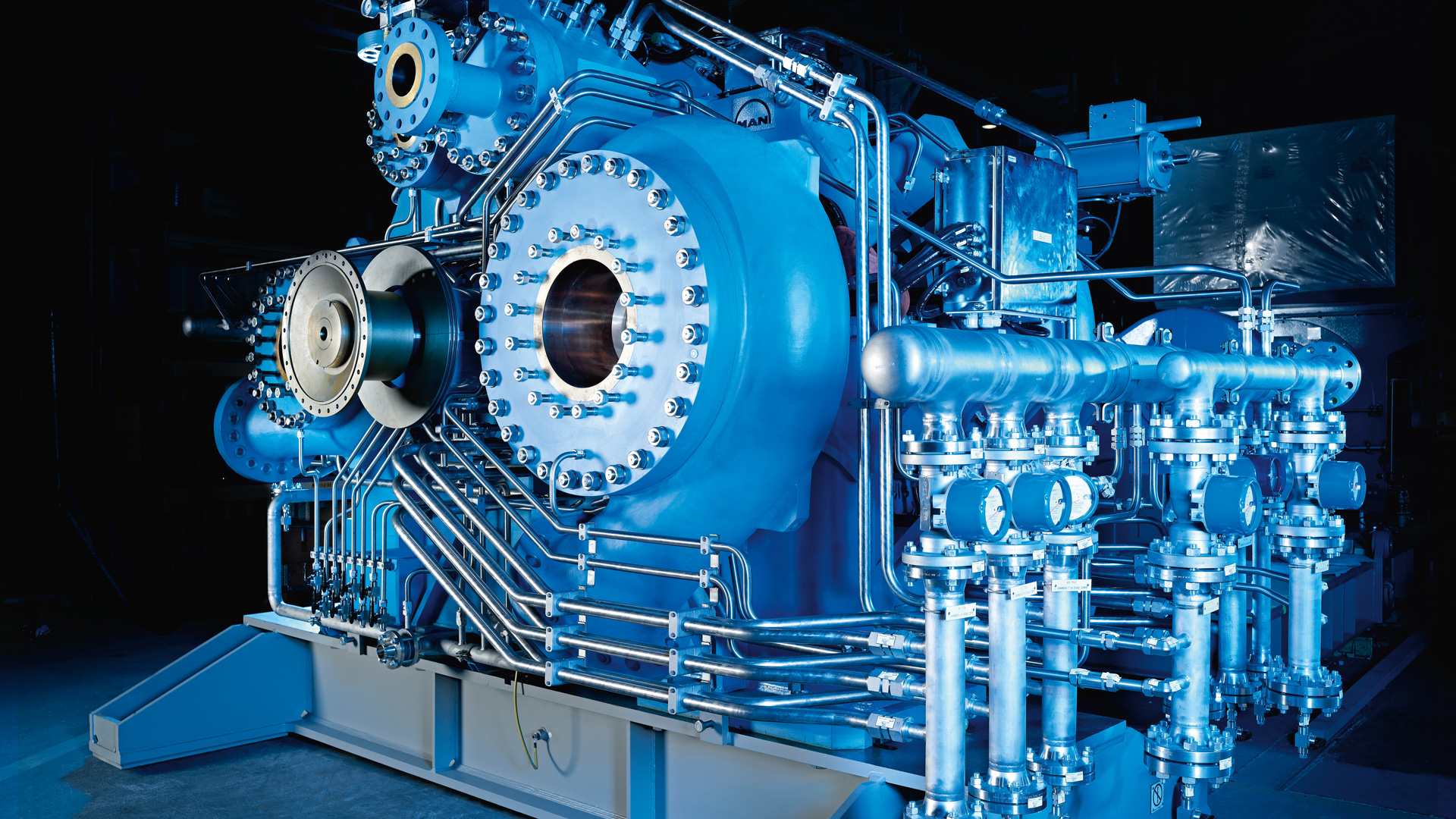

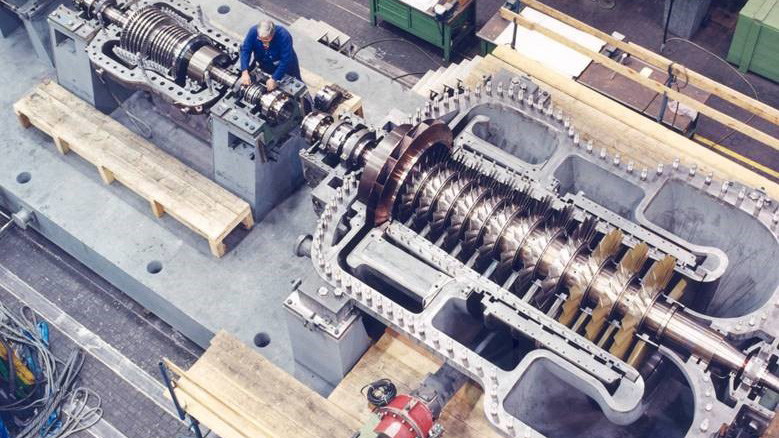

Integrally geared compressors

Our integrally geared centrifugal compressors are used for tailgas or syngas compression, for refrigerants, for high pressure CO2 processes and more. These compressors are exceptionally compact, minimizing the need for space. They are driven by an electric motor or a turbine drive. They are especially popular in the industry thanks to their ultra-high efficiency, flexibility and easy process integration.

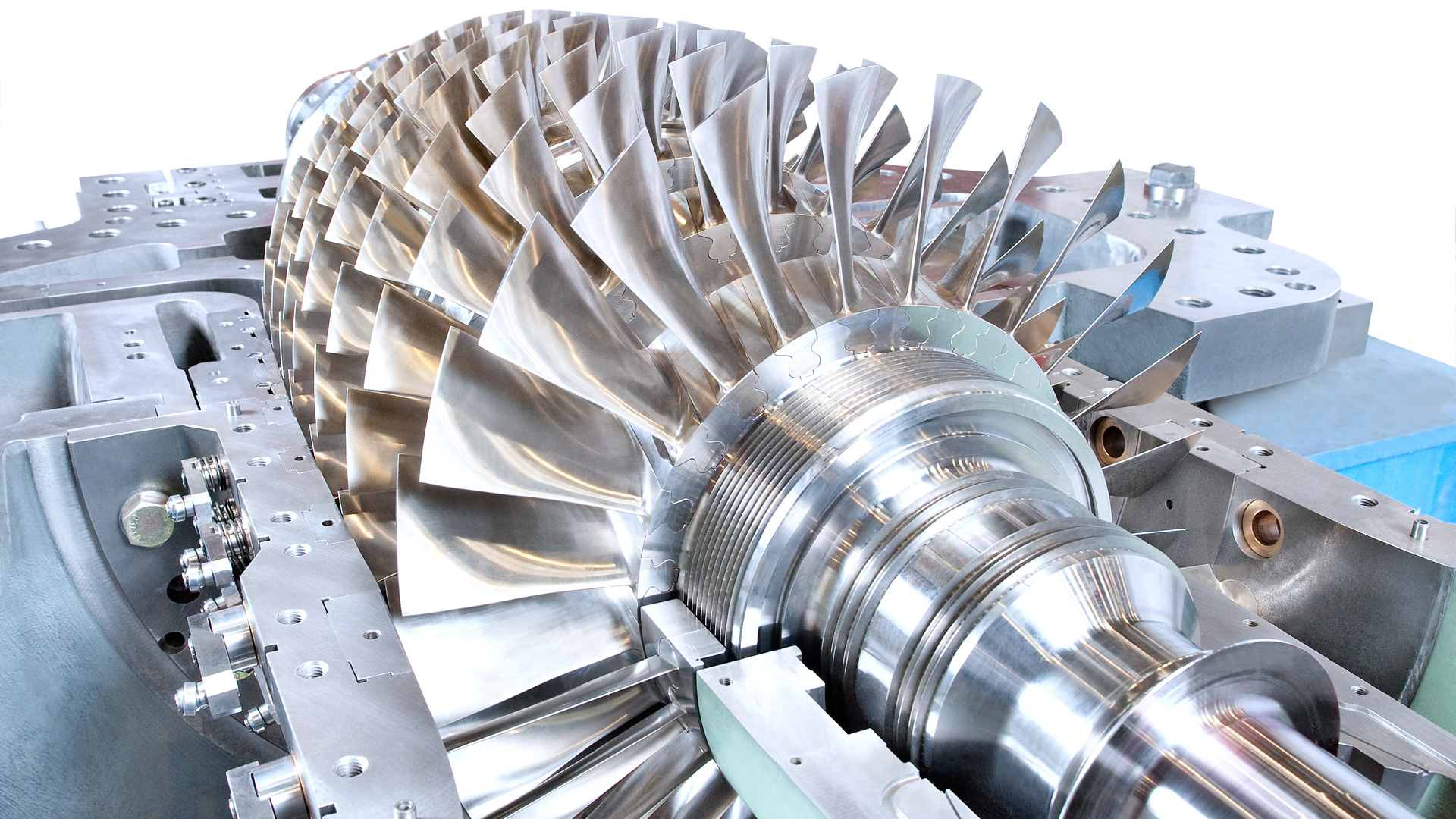

Go to integrally geared compressorsAxial compressors

Our heavy-duty axial compressors are used for fluid catalytic cracking applications. MAN Energy Solutions offers various types of axial flow compressors to meet your specific needs. Our axial compressors are highly robust and well-proven, employed all over the globe in the refinery and various other industries. Our revolutionary MAX1 can deliver flows of up to 1.5M m3./h

Our heavy-duty axial compressors are used for fluid catalytic cracking applications. MAN Energy Solutions offers various types of axial flow compressors to meet your specific needs. Our axial compressors are highly robust and well-proven, employed all over the globe in the refinery and various other industries. Our revolutionary MAX1 can deliver flows of up to 1.5M m3./h

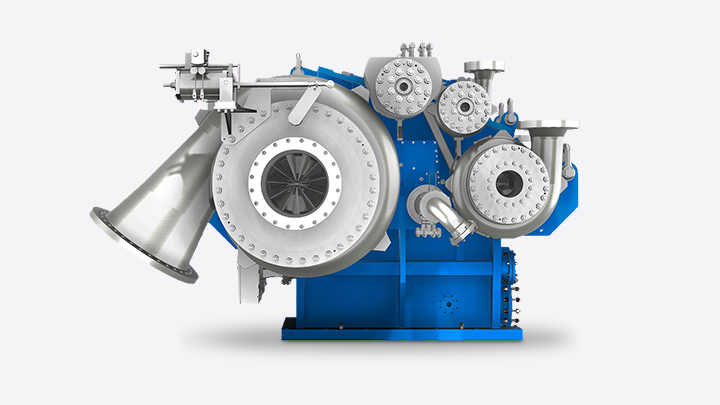

Centrifugal compressors

Increasing the efficiency of your operations will be high on your list of priorities. MAN Energy Solutions centrifugal compressors can deal with vast volume flows and require little downtime, increasing your ROI on a daily basis.

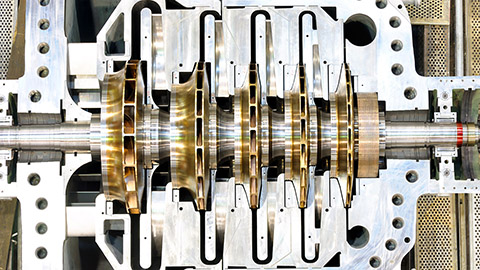

Go to centrifugal compressorsSteam turbines

MAN Energy Solutions steam turbines with a power range between 1 - 180 MW feature proven reliability and modular design and can be scaled for special process and customer requirements. Our customers in the process industries, from refineries to fertilizer, rely on our highly efficient steam turbines in their mechanical drives.

MAN Energy Solutions steam turbines with a power range between 1 - 180 MW feature proven reliability and modular design and can be scaled for special process and customer requirements. Our customers in the process industries, from refineries to fertilizer, rely on our highly efficient steam turbines in their mechanical drives.

Carbon capture, utilization, and storage

Petrochemical plants emit a lot of CO2 in flue gases. Capturing this CO2 allows it to be used and stored. Once purified, CO2 can be compressed and transported to facilities that use it to make synthetic fuels, beverages, dry ice, and chemicals. We also have ways of storing CO2 permanently underground. We provide the technology for compressing and liquefying CO2, and for heat recovery and heat integration to reduce costs at your plant.

More on carbon capture

MAN PrimeServ keeps your turbomachinery running

Our service engineers provide preventive maintenance, assist your troubleshooting, and get your facilities up and running in no time – wherever and whenever you need them.

How you benefit:

- Fast, reliable and expert customer support

- Bespoke service agreements

- Global service – 24 hours a day, 365 days a year

A wide range of different refinery applications

We supplied a range of reference compressors for the first and second expansion stage of the largest refinery in the world. MAN established and conducted an after-sales service workshop.

| Location: | Gujarat, India |

| Application: | Various refinery applications, i.e. FCC |

| Project status: | Completed in 2004 |

| Customer benefits: |

|

| MAN’s scope of work: | 57 casings including ST generator sets |

Download

-

Heat pumps for process industriespdf, 2130 KB

Contact our MAN Oil & Gas support team

Prepare your business for growing demand, increasing environmental regulations and volatile markets.

Choose individual components or entire trains or reactors to suit your needs from our range of pre-engineered, modular packaged design solutions. Find out what is right for your business.

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.