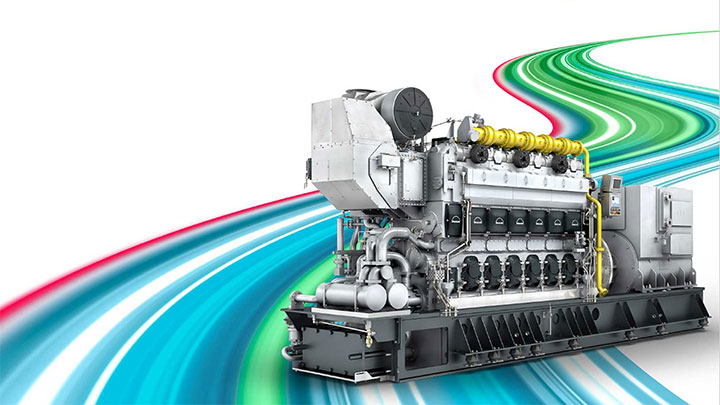

Reliable and efficient four-stroke small-bore engines

Regulatory and fuel-related uncertainty can make it difficult to plan investments in propulsion and GenSets. With our small-bore engines, you are prepared for whatever lies ahead.

MAN Energy Solutions has built its position as the leading designer and developer of small-bore engines for the world’s merchant marine fleet on the basis of high reliability and efficiency.

Thanks to the low maintenance requirements, our engines provides extended lifetime, and additionally offer long time between overhauls (TBO). When needed, our service experts are there for you – every day and everywhere around the world.

MAN small-bore engine portfolio for the world’s merchant fleet

across the globe

Key benefits

Full range of MAN four-stroke small-bore engines

Explore the capabilities and range of our engines.

GenSets and Diesel-electric propulsion

MAN L28/32DF GenSet

Based on the ultra-reliable and robust MAN 28/32H, the dual-fuel version is available as newbuild or retrofit and adds the ability to run on methane, with its economic and environmental advantages. High efficiency in gas and diesel mode makes it a perfect GenSet as part of a complete power package with four-stroke or two-stroke propulsion engines. Easy operation, easy maintenance and proven reliability also make it a trusted propulsion engine with long times between overhauls and low life cycle costs.

- 720 – 750 rpm

- 1,050 – 1,890 kW

- 1,000 – 1,800 kWe

MAN L23/30H Mk3 GenSet

By applying innovative technology to classic design principles, the MAN L23/30H Mk3 is engineered to meet the power needs of most commercial ship types. Straight forward integration requirements make it a perfect choice for low-cost installation, while well-known maintenance procedures and common spare parts reduce operating costs. The new model raises power output per cylinder by 15-20% and reduces fuel oil consumption.

- 720 – 900 rpm

- 500 – 1,800 kW

- 475 – 1,710 kWe

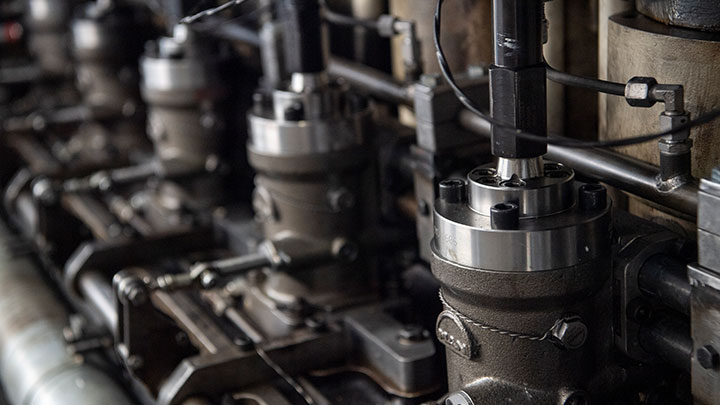

MAN L23/30DF GenSet

The MAN L23/30DF dual-fuel GenSet lets you select the most economic fuel for the operating condition. The cost optimized fuel injection system is designed for high reliability and cost-efficiency. It uses the main injection valve to inject pilot oil. This way, separate injectors, piping and pumps for main oil and pilot oil or a common rail system are not needed, saving on installation costs and maintenance. The monocoque design also eases the installation of the engine series and reduces weight.

- 720 – 900 rpm

- 625 – 1,320 kW

- 590 – 1,255 kWe

This methanol-fuelled engine is a compact and reliable power source designed to run on methanol, heavy fuel oil (HFO), and most bio-fuel oils. When powered by green methanol, it is carbon neutral. The new engine type maintains the reliability and low consumption of the proven MAN 21/31, ensuring security of power supply on large vessels and handling load steps with confidence.

- 900 – 1,000 rpm

- 1,000 – 1,980 kW

- 950 – 1,880 kWe

Propulsion engines

The robust and reliable MAN L27/38 delivers good performance over the entire load range with quick acceleration and immediate load response. Its proven reliability ensures long time between overhauls (TBO) and no unscheduled maintenance or repair work.

This engine is available as methanol-ready version.

- 750 – 900 rpm

- 2,100 – 3,690 kW

MAN L21/31 propulsion

The MAN L21/31 engine combines intelligent use of fuel in marine applications with flexible propulsion systems. It is the ideal power source, for example, for small to medium-sized tankers, cargo ships and ferries.

The proven engine is characterized by its reliability and low consumption.

This engine is available as methanol-ready version.

- 1,000 rpm

- 1,290 – 1,935 kW

Plan your vessel with confidence

Get in touch with our four-stroke small-bore experts for in-depth advice on all your propulsion and GenSet questions. Start your change process now and reach out to us today.

Continue reading

Related content

-

MAN L21/31DF-M and MAN L27/38DF-M

Discover our methanol-fuelled small-bore engines: MAN L21/31DF-M and MAN L27/38DF-M.

-

Methanol GenSet

Engineers in Denmark are making shipboard power low-emission with the developing of a four-stroke methanol engine.

Related news

World’s Most Powerful Methanol Engine Announced

MAN Energy Solutions has announced that it will deliver the world's most powerful two-stroke methanol engine in June 2025. The engine, an MAN B&W 12G95ME-C10.5-LGIM (-Liquid Gas Injection Methanol) type rated at 82,440 kW @ 80rpm, is currently being built by Chinese licensee, CSSC-MES Diesel Co., Ltd. (CMD).

The engine is the first of 12 bound for a series of 12 × 24,000 teu container vessels currently under construction: seven at Nantong COSCO KHI Ship Engineering Co., Ltd. (NACKS) for shipowner, Orient Overseas Container Line Ltd. (OOCL); and five at Dalian COSCO KHI Ship Engineering Co., Ltd. (DACKS) for shipowner, COSCO Shipping Lines Co., Ltd. Each engine will also feature MAN Energy Solutions’ proprietary EGRTC (Exhaust Gas Recirculation Turbocharger Cut-out) emissions system, the largest two-string EGR system on a two-stroke engine to date.

Bjarne Foldager – Head of Two-Stroke Business – MAN Energy Solutions, said: “At MAN Energy Solutions, our vision of 'Moving Big Things to Zero' motivates everything we do in developing the engine technology to operate on those fuels vying for prominence in the future market. This latest, remarkable milestone – the world’s most powerful methanol engine – is just the latest fulfilment of that. By harnessing the potential of methanol, we are bringing the maritime industry closer to zero-emission solutions and we fully expect methanol to figure prominently as a future-fuel across all segments. Our thanks go to CMD, OOCL and COSCO Shipping, valued partners with whom we continue to share so many highlights.”

Christian Ludwig – Head of Two-Stroke Sales and Promotion – MAN Energy Solutions, said: “As we move towards a multi-fuel future, interest in methanol has grown steadily. To date, between newbuild engines and retrofits, we have won over 230 ME-LGIM references that have accumulated over 600,000 hours running on methanol alone. With ME-LGIM technology reaching 10 years in the market, it represents mature, proven technology and reflects MAN Energy Solutions’ ability to develop attractive technology to enable shipping’s carbon transition. Furthermore, while methanol produced from renewable sources is an attractive marine-fuel option due to its low carbon-intensity, an engine using green methanol can even provide carbon-neutral propulsion – adding to the benefits the ME-LGIM brings to the table.”

About the MAN B&W ME-LGIM engine

MAN Energy Solutions developed the ME-LGIM dual-fuel engine for operation on methanol, as well as conventional fuel. The engine is based on the company’s proven ME-series, with its approximately 8,500 engines in service, and works according to the Diesel principle. When operating on green methanol, the engine offers carbon-neutral propulsion for large merchant-marine vessels.

Methanol carriers have already operated at sea for many years using the engine, and, as such, the ME-LGIM has a proven track record offering great reliability and high fuel-efficiency.

Documents

-

PR COSCO ME-LGIM_EN

Contact

Nils Søholt

Trade Press Marine

Group Communications & MarktingEverllenceTeglholmsgade 412450 Copenhagen SVDenmark

nils.soeholt@everllence.com t +45 33 85 26 69Available languages

- DE ·

- EN

Get notified about press releases

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.