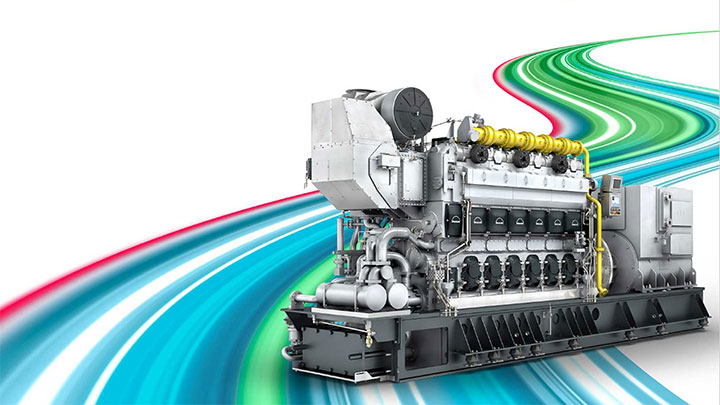

Reliable and efficient four-stroke small-bore engines

Regulatory and fuel-related uncertainty can make it difficult to plan investments in propulsion and GenSets. With our small-bore engines, you are prepared for whatever lies ahead.

MAN Energy Solutions has built its position as the leading designer and developer of small-bore engines for the world’s merchant marine fleet on the basis of high reliability and efficiency.

Thanks to the low maintenance requirements, our engines provides extended lifetime, and additionally offer long time between overhauls (TBO). When needed, our service experts are there for you – every day and everywhere around the world.

MAN small-bore engine portfolio for the world’s merchant fleet

across the globe

Key benefits

Full range of MAN four-stroke small-bore engines

Explore the capabilities and range of our engines.

GenSets and Diesel-electric propulsion

MAN L28/32DF GenSet

Based on the ultra-reliable and robust MAN 28/32H, the dual-fuel version is available as newbuild or retrofit and adds the ability to run on methane, with its economic and environmental advantages. High efficiency in gas and diesel mode makes it a perfect GenSet as part of a complete power package with four-stroke or two-stroke propulsion engines. Easy operation, easy maintenance and proven reliability also make it a trusted propulsion engine with long times between overhauls and low life cycle costs.

- 720 – 750 rpm

- 1,050 – 1,890 kW

- 1,000 – 1,800 kWe

MAN L23/30H Mk3 GenSet

By applying innovative technology to classic design principles, the MAN L23/30H Mk3 is engineered to meet the power needs of most commercial ship types. Straight forward integration requirements make it a perfect choice for low-cost installation, while well-known maintenance procedures and common spare parts reduce operating costs. The new model raises power output per cylinder by 15-20% and reduces fuel oil consumption.

- 720 – 900 rpm

- 500 – 1,800 kW

- 475 – 1,710 kWe

MAN L23/30DF GenSet

The MAN L23/30DF dual-fuel GenSet lets you select the most economic fuel for the operating condition. The cost optimized fuel injection system is designed for high reliability and cost-efficiency. It uses the main injection valve to inject pilot oil. This way, separate injectors, piping and pumps for main oil and pilot oil or a common rail system are not needed, saving on installation costs and maintenance. The monocoque design also eases the installation of the engine series and reduces weight.

- 720 – 900 rpm

- 625 – 1,320 kW

- 590 – 1,255 kWe

This methanol-fuelled engine is a compact and reliable power source designed to run on methanol, heavy fuel oil (HFO), and most bio-fuel oils. When powered by green methanol, it is carbon neutral. The new engine type maintains the reliability and low consumption of the proven MAN 21/31, ensuring security of power supply on large vessels and handling load steps with confidence.

- 900 – 1,000 rpm

- 1,000 – 1,980 kW

- 950 – 1,880 kWe

Propulsion engines

The robust and reliable MAN L27/38 delivers good performance over the entire load range with quick acceleration and immediate load response. Its proven reliability ensures long time between overhauls (TBO) and no unscheduled maintenance or repair work.

This engine is available as methanol-ready version.

- 750 – 900 rpm

- 2,100 – 3,690 kW

MAN L21/31 propulsion

The MAN L21/31 engine combines intelligent use of fuel in marine applications with flexible propulsion systems. It is the ideal power source, for example, for small to medium-sized tankers, cargo ships and ferries.

The proven engine is characterized by its reliability and low consumption.

This engine is available as methanol-ready version.

- 1,000 rpm

- 1,290 – 1,935 kW

Plan your vessel with confidence

Get in touch with our four-stroke small-bore experts for in-depth advice on all your propulsion and GenSet questions. Start your change process now and reach out to us today.

Continue reading

Related content

-

MAN L21/31DF-M and MAN L27/38DF-M

Discover our methanol-fuelled small-bore engines: MAN L21/31DF-M and MAN L27/38DF-M.

-

Methanol GenSet

Engineers in Denmark are making shipboard power low-emission with the developing of a four-stroke methanol engine.

Related news

World’s First VLCV Methanol Retrofit Represents Blueprint for Future Projects

MAN Energy Solutions has announced the successful retrofit of the main engine of the ‘Maersk Halifax’ to a dual-fuel MAN B&W ME-LGIM unit. MAN PrimeServ, MAN Energy Solutions’ after-sales division, carried out the work, the first such project globally involving a VLCV (Very Large Container Vessel).

The 15,000 teu vessel entered service in 2017 and was originally powered by an MAN B&W 8G95ME-C9.5 prime mover. The retrofit to an 8G95ME-LGIM Mk10.5 engine enables the Maersk Halifax to operate on green methanol, making it possible to reduce its CO2 emissions by 90%.

The retrofit also included an upgrade to the vessel’s engine-control system to MAN Energy Solutions’ latest Triton system. Following the completion of sea-trials, Maersk Halifax has returned to operation and is now servicing A.P. Moller - Maersk’s (Maersk) Trans-Pacific trade.

Leonardo Sonzio, Head of Fleet Management and Technology at Maersk, said: “Since we set the ambitious climate goal of reaching net zero emissions by 2040, we have explored the potential in retrofitting existing vessels with dual-fuel engines. In the coming year, we will take learnings from this first conversion of a large vessel. Retrofits of existing vessels can be an important alternative to newbuilds in our transition from fossil fuels to low-emission fuels.”

The Halifax retrofit is expected to serve as a blueprint for future retrofit projects. Indeed, Maersk has already placed a preorder for MAN PrimeServ to convert an additional 10 vessels from its fleet to methanol operation.

Michael Petersen, Senior Vice President and Head of PrimeServ Denmark, praised the project collaboration with Maersk and Asia Pacific and said: “Retrofits are one of the five growth areas identified in MAN Energy Solutions’ ‘Moving Big Things To Zero’ strategy, enabling shipowners to drastically reduce CO2 emissions without having to commission newbuilds. Retrofitted engines are able to switch between fuels with minimal disruption, flexibility that is crucial for maintaining operational efficiency and reliability. At PrimeServ, we estimate that more than 4,000 existing marine engines have the potential to be converted to operation on green fuels like e-methanol and e-methane.”

Speaking at a recent event at Asia Pacific Dockyard in Zhoushan to mark the project’s conclusion, Sarath Prasannan, Senior Vice President and Head of Region Asia Pacific, said: “This groundbreaking project marks a pivotal moment in the shipping industry's journey towards decarbonisation. We hope that China's policies and infrastructure will continue to foster an environment where shipyards can carry forward this commendable work.”

About Maersk

A.P. Moller - Maersk is an integrated logistics company working to connect and simplify its customers’ supply chains. As a global leader in logistics services, the company operates in more than 130 countries and employs around 100,000 people. Maersk is aiming to reach net zero emissions by 2040 across the entire business with new technologies, new vessels, and alternative fuels.

Documents

-

PR PrimeServ Halifax_EN

Contact

Nils Søholt

Trade Press Marine

Group Communications & MarktingMAN Energy SolutionsTeglholmsgade 412450 Copenhagen SVDenmark

nils.soeholt@man-es.com t +45 33 85 26 69Available languages

- DE ·

- EN