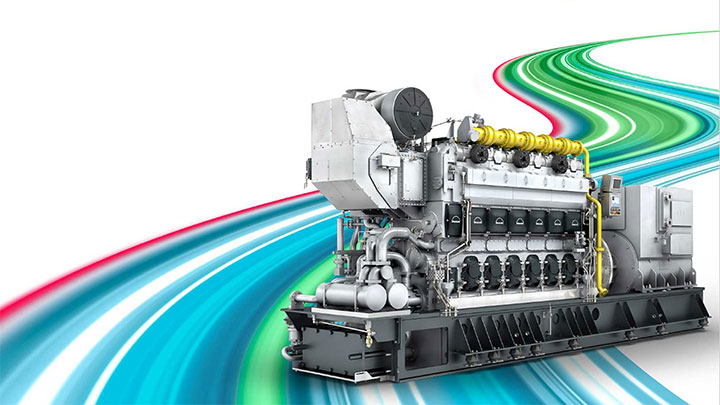

Reliable and efficient four-stroke small-bore engines

Regulatory and fuel-related uncertainty can make it difficult to plan investments in propulsion and GenSets. With our small-bore engines, you are prepared for whatever lies ahead.

MAN Energy Solutions has built its position as the leading designer and developer of small-bore engines for the world’s merchant marine fleet on the basis of high reliability and efficiency.

Thanks to the low maintenance requirements, our engines provides extended lifetime, and additionally offer long time between overhauls (TBO). When needed, our service experts are there for you – every day and everywhere around the world.

MAN small-bore engine portfolio for the world’s merchant fleet

Key benefits

Full range of MAN four-stroke small-bore engines

Explore the capabilities and range of our engines.

GenSets and Diesel-electric propulsion

MAN L28/32DF GenSet

Based on the ultra-reliable and robust MAN 28/32H, the dual-fuel version is available as newbuild or retrofit and adds the ability to run on methane, with its economic and environmental advantages. High efficiency in gas and diesel mode makes it a perfect GenSet as part of a complete power package with four-stroke or two-stroke propulsion engines. Easy operation, easy maintenance and proven reliability also make it a trusted propulsion engine with long times between overhauls and low life cycle costs.

- 720 – 750 rpm

- 1,050 – 1,890 kW

- 1,000 – 1,800 kWe

MAN L23/30H Mk3 GenSet

By applying innovative technology to classic design principles, the MAN L23/30H Mk3 is engineered to meet the power needs of most commercial ship types. Straight forward integration requirements make it a perfect choice for low-cost installation, while well-known maintenance procedures and common spare parts reduce operating costs. The new model raises power output per cylinder by 15-20% and reduces fuel oil consumption.

- 720 – 900 rpm

- 500 – 1,800 kW

- 475 – 1,710 kWe

MAN L23/30DF GenSet

The MAN L23/30DF dual-fuel GenSet lets you select the most economic fuel for the operating condition. The cost optimized fuel injection system is designed for high reliability and cost-efficiency. It uses the main injection valve to inject pilot oil. This way, separate injectors, piping and pumps for main oil and pilot oil or a common rail system are not needed, saving on installation costs and maintenance. The monocoque design also eases the installation of the engine series and reduces weight.

- 720 – 900 rpm

- 625 – 1,320 kW

- 590 – 1,255 kWe

This methanol-fuelled engine is a compact and reliable power source designed to run on methanol, heavy fuel oil (HFO), and most bio-fuel oils. When powered by green methanol, it is carbon neutral. The new engine type maintains the reliability and low consumption of the proven MAN 21/31, ensuring security of power supply on large vessels and handling load steps with confidence.

- 900 – 1,000 rpm

- 1,000 – 1,980 kW

- 950 – 1,880 kWe

Propulsion engines

The robust and reliable MAN L27/38 delivers good performance over the entire load range with quick acceleration and immediate load response. Its proven reliability ensures long time between overhauls (TBO) and no unscheduled maintenance or repair work.

This engine is available as methanol-ready version.

- 750 – 900 rpm

- 2,100 – 3,690 kW

MAN L21/31 propulsion

The MAN L21/31 engine combines intelligent use of fuel in marine applications with flexible propulsion systems. It is the ideal power source, for example, for small to medium-sized tankers, cargo ships and ferries.

The proven engine is characterized by its reliability and low consumption.

This engine is available as methanol-ready version.

- 1,000 rpm

- 1,290 – 1,935 kW

Plan your vessel with confidence

Get in touch with our four-stroke small-bore experts for in-depth advice on all your propulsion and GenSet questions. Start your change process now and reach out to us today.

Continue reading

Related content

-

MAN L21/31DF-M

The MAN L21/31DF-M methanol GenSet is the first small-bore dual-fuel methanol GenSet in our portfolio.

-

Methanol GenSet

Engineers in Denmark are making shipboard power low-emission with the developing of a four-stroke methanol engine.

Related news

MAN Cryo Supplies Fuel System for World’s First Hydrogen-Powered Superyacht

MAN Cryo has supplied a liquid-hydrogen gas-fuel supply system to a 118.8 m superyacht constructed by Feadship, the Dutch designer and builder. Known as ‘Project 821’, the newbuilding is the world's first hydrogen fuel-cell superyacht.

MAN Cryo’s fuel-gas system will store the hydrogen in liquid form, evaporate and heat it, and supply gaseous hydrogen to the fuel cell enabling the zero-emission propulsion of the vessel. The company is a division of MAN Energy Solutions and a leading expert within engineering solutions for cryogenic equipment for the storage, distribution, and handling of gasses.

Henrik Malm, Managing Director – MAN Energy Solutions Sweden, said: “This notable project showcases MAN Energy Solutions' leadership within the development of future-fuel systems for the maritime sector. In particular, MAN Cryo is setting new standards in sustainability and engineering with its system design and the innovative positioning of the vessel’s fuel-tanks below deck. Congratulations to Feadship on its dedication to decarbonisation and pushing the green envelope within the superyacht segment.”

Although hydrogen fuel-cells have existed commercially for over six decades, no solution had previously been available within the maritime sector. Project 821’s fuel-cell technology can provide an entire week's worth of silent operation at anchor, or emission-free navigation at 10 knots when departing harbours or cruising in protected marine zones with pure water being the only emission.

Challenges

MAN Cryo faced a number of challenges during the project, in great part owing to the lack of existing design codes and standards to follow in order to get approval for its tank design. Normally, type C LNG tanks are designed according to IGF code, but this is not fully applicable to hydrogen.

Instead, MAN Cryo approached Lloyds Register with a risk-assessment-based design that is considered safe and approved for placement below deck, a first of its kind in the world and just the second ever for a marine liquid-hydrogen project.

MAN Cryo’s scope of supply for the project includes:

- a 92 m3 vacuum-insulated type C tank, storing liquid hydrogen at -253 degrees Celsius;

- a tank connection space (TCS) including necessary process equipment such as vaporizers, control valves, safety valves, etc;

- a bunker station, enabling shore-to-ship bunkering of liquid hydrogen;

- control and automation systems, including the groundbreaking ‘tank prediction tool’, a feature that simulates tank pressure and tank-filling levels and helps crew to predict and plan bunkering operations;

- a vent mast;

- interconnecting hydrogen piping.

Sofia Liedholm, Project Manager – MAN Cryo, said: “The alternative design-approval process proved challenging from time to time but – thanks to good cooperation between MAN Cryo, Lloyd´s Register and Feadship – we managed to successfully resolve all issues. MAN Cryo is a frontrunner when it comes to marine fuel systems and, from this project, we now have further knowledge to bring with us into whatever the next opportunity will be to develop a more sustainable marine sector.”

About MAN Cryo

Based in Gothenburg, Sweden, MAN Cryo offers system design and engineering solutions for the storage, distribution and handling of liquefied gases and has a pioneering reputation within the marine sector. It supplied the world’s first LNG fuel-gas system for the ‘Glutra’ ferry in Norway in 1999, while in 2013 it supplied the world’s first LNG bunker vessel – the ‘SeaGas’ – with operations in Stockholm, Sweden. More recently, MAN Cryo has signed its first design contracts for methanol-supply systems, and obtained an approval in principle from several classing societies for its ammonia fuel-supply system.

Contact: Reinert Magnusson – Head of Cryo

Documents

-

PR Feadship_H2_EN

Contact

Nils Søholt

Trade Press Marine

Group Communications & MarktingMAN Energy SolutionsTeglholmsgade 412450 Copenhagen SVDenmark

nils.soeholt@man-es.com t +45 33 85 26 69Available languages

- DE ·

- EN