Innovating and evolving to meet your needs

The costs of turbine recovery and downtime are a constant drag on the efforts of wind operators to minimize the levelized cost of energy (LCOE). By expanding the range of in-situ recovery we help shorten standstills and enable substantial savings.

In the transformation toward a decarbonized future energy mix, wind power is successfully established as a cost-competitive player driven by constant innovation. At MAN PrimeServ we know you need us to be equally innovative in finding new and better ways to make up-tower recovery. Our engineers and in-house design team interface with you to come up with the fastest and most effective recovery possible. As an OEM in energy and storage technology and a seasoned service solutions provider, we understand the importance of tailoring our services to your unique needs.

How you benefit:

- Get your turbine back in operation fast

- Trust the outcome of recoveries: We recover equipment to the manufacturer’s specifications

- Our services are certified to the standards ISO 9001, 14001 and 18001

- Leverage our cross-manufacturer expertise: We service equipment from every manufacturer

Up-tower, onshore and offshore

We have developed the following on-site services which we now perform frequently on wind turbines of different makes and sizes, generally from 2MW and up.

- Generator shaft recovery (DE and NDE)

- Tooth recovery

- Yaw ring recovery

- Hollow shaft recovery

- Stud & thread recovery

- Flange recovery

- Metal stitching

- Laser recovery

- Customized recovery

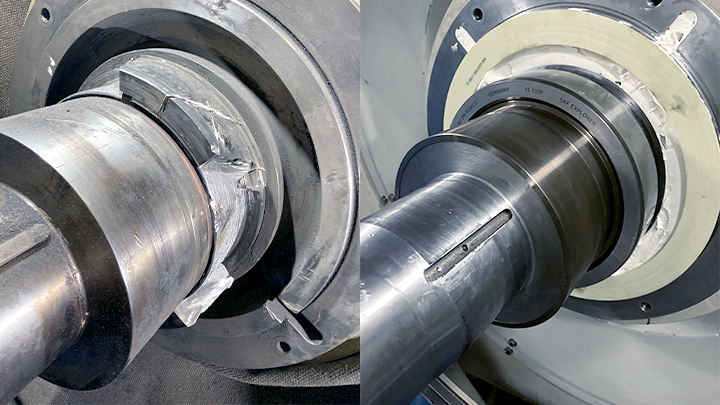

Generator shaft recovery

Damage to the generator shaft is most frequently caused by different degrees of ball bearing seizure. We have the tools and the experience to perform up-tower recovery of the shaft for different wind turbine models of 2 MW and larger. After machining the damaged shaft, the basis material is tested for micro cracks, hardness, and roughness. Finally, a pre-made bushing is shrink-fitted to restore the original dimensions of the generator shaft. Complete recovery of the shaft to manufacturer’s specifications is performed in three days.

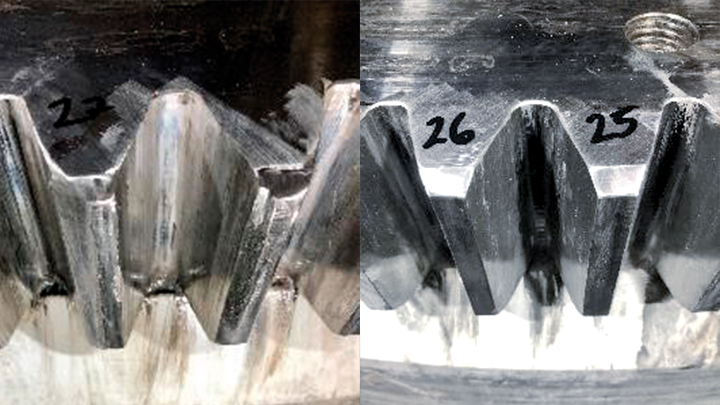

Tooth recovery

When a yaw ring tooth or series of teeth has been worn or damaged, the fastest and most cost-effective way of bringing the yaw ring back to original specifications is on-site recovery. Onshore or offshore, our team of specialists will use a combination of machining, welding, and polishing to recover the damaged area tooth by tooth. Depending on the damage, the area or tooth will be machined to achieve a clean surface, new material will be added by welding and the final shape and surface of the tooth achieved by polishing. Finally, thorough measurements of each tooth ensure that all specifications are met, making the wind turbine fully operational again.

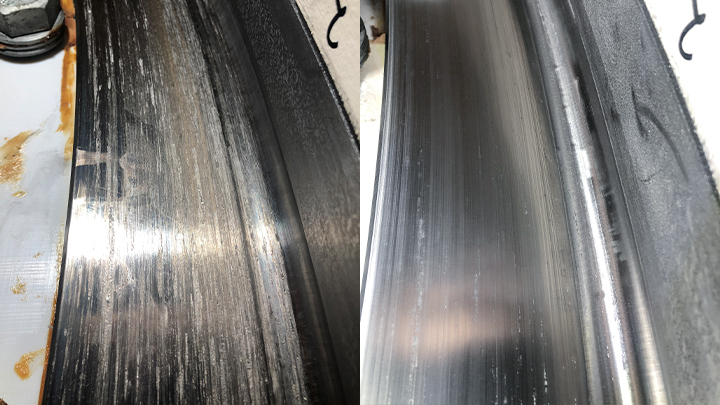

Yaw ring recovery

In cases where the surface of the yaw ring has been scratched, typically by a spring or a claw, rectification is necessary to assure continued optimal operation of the wind turbine. A specialized tool is mounted to hone the surface back to acceptable roughness while rotating the nacelle. Final measurements ensure that the achieved surface roughness is within the specified tolerances. The entire procedure takes a couple of days on average, depending on the severity of the damage.

Recovery of the brake surface

on a yaw ring

A spring pad failure brought the spring into direct contact with the yaw ring’s brake surface, causing severe scratches along the surface.

MAN PrimeServ’s repair team brought their workshop and tools to the 2-MW turbine tower. Utilizing the turbine’s capability to rotate the nacelle for their purpose, they honed the brake surface using a specialized tool, avoiding the more costly and time-consuming replacement of the yaw ring.

Customer type | Utility |

| Windpark | Onshore |

| Turbine size | 2MW |

How can we help you?

Up-tower recovery decisions come down to two questions: What will they cost? How long will they take. Talk to us and get reliable answers for your particular case. On top of our portfolio of recovery services, we offer recoveries tailored to your needs. We thrive on challenges. Try us!