Decarbonize with proven gas and dual fuel engines

As a major contributor to CO2 emissions, the energy sector is facing tightening regulations and is looking for ways to become independent from fossil fuels. The paths to net zero exist, but so do numerous practical obstacles. Decarbonization is not only about net zero but also the steps towards net zero.

On the path to net zero, MAN gas engines and dual fuel engines are bridging technology. They allow you to lower carbon emissions now with technology that can be upgraded or retrofitted at a later date. As individual products or as part of CHP, base load or peaking plants, MAN engines are a future-proof investment in power and heat generation.

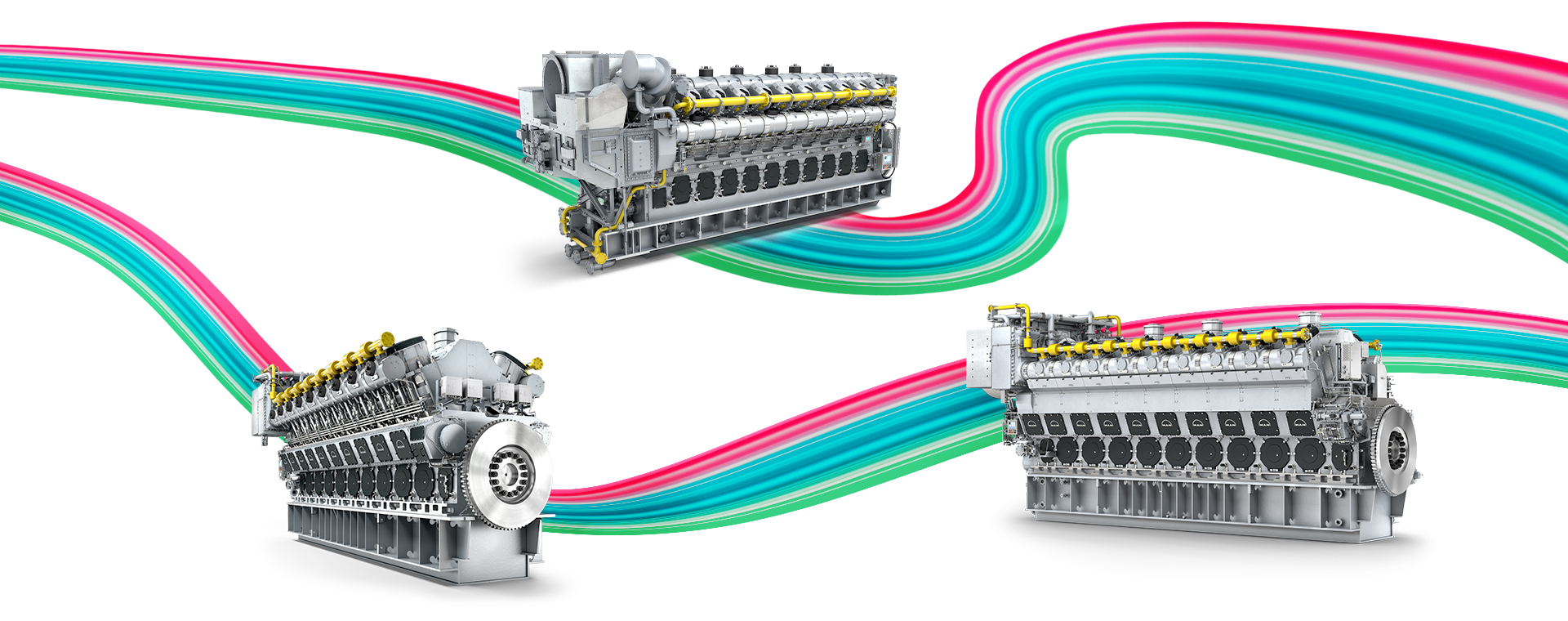

MAN gas and dual fuel engines

Reciprocating engines have the highest electrical efficiency, are very dynamic (fast ramp up, ramp down, part load), and allow modular plant design with multiple units to optimize operation and thermal management. Our gas and dual fuel engines are a future-proof

investment in a low-carbon future.

MAN 51/60G

With best-in-class power output and low emissions, the MAN 51/60G is setting new standards for gas engines. It is also available with two-stage turbocharging for superior performance.

MAN 35/44G

This compact engine delivers ultimate performance and top efficiency with low emissions. It is also available with two-stage turbocharging.

MAN 51/60DF

This dual fuel engine converts diesel or natural gas efficiently and can switch from one fuel to another without any fluctuations in speed or output. It's also possible to easily upgrade our MAN 51/60 engine to dual fuel capability if necessary. Also available with two-stage turbocharging.

Flexible, scalable, future-proof gas and dual fuel engine solutions

The challenge is to provide the highest possible grid stability while maintaining adaptability to future regulations and market conditions. The answer is in MAN’s gas engine technology. Its ability to run on 100% biogas ensures independence from natural gas supplies. The following selection of projects show how gas and dual fuel engines can lower the CO2 emissions of utilities and industrial plants using smart thermal management. To create additional revenue streams, gas power plants can be operated as thermal balancing units in RES grids.

CHP

MAN 12V35/44G TS for Schwäbisch Hall

MAN fully commissioned the new combined heat and power plant for the town of Schwäbisch Hall in southern Germany, supplying two MAN 12V35/44G TS gas engines to replace the plant’s two 3MW engines. As a result, the Schwäbisch Hall CHP plant now achieves a fuel efficiency of up to 90% and an electrical efficiency of 47%. It also uses biomethane as fuel, thereby reducing its dependence on natural gas supplies.

Learn more about CHP in utilityPeaking

24 x MAN 20V35/44G TS for Statera Energy, UK

Statera Energy will use 24 MAN 20V35/44G TS gas engines in six new power plants to deliver a total of 300 MW of highly efficient back-up power to the UK national grid. Our gas engines provide market-leading fuel efficiency and low emissions. The engines can also be operated on 100% climate-neutral synthetic natural gas as soon as it is available. This means that Statera’s new plants are future-proofed and have the potential to contribute to a fully decarbonized economy.

Read the full article on gas engine power plantsLNG

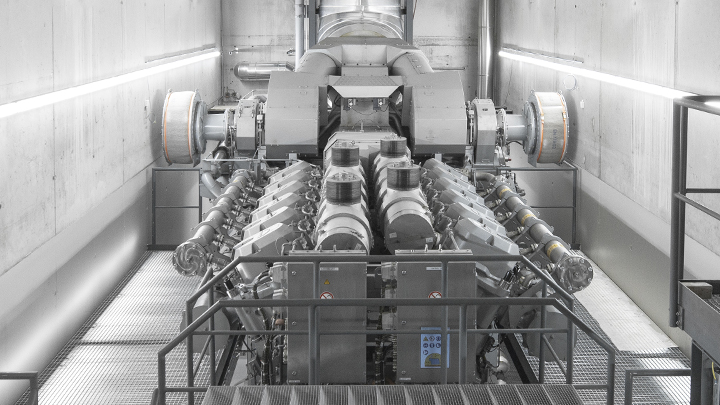

MAN 14V51/60G and DF for Gibraltar Harbour

The power plant on the North Mole in Gibraltar Harbour provides the basis for the territory’s power supply – with an output far exceeding Gibraltar's current peak demand. MAN Energy Solutions delivered three gas and three dual fuel engines for the plant, which uses combined heat and power for increased efficiency.

Discover how Gibraltar builds a modern LNG power plantBase load

MAN 18V51/60DF for Kodda, Bangladesh

Although Bangladesh is the seventh-largest natural gas producer in Asia, a reliable, steady supply was not always assured. Therefore, the nine MAN engines at the Kodda power plant initially ran on diesel. After the supply infrastructure for operation on natural gas was finished, the engines were retrofitted to dual fuel and now offer the fuel flexibility the plant operators wanted and the security of supply Bangladesh needs.

Learn more on fueling KoddaAlternative fuels for net zero

Our future-proof gas and dual fuel engines offer a clear path toward net zero. Even today, CO2 emissions can be further reduced by using 100% SNG or 100% biofuels or by blending up to 25% hydrogen. Carbon-neutral fuels such as methanol and carbon-free fuels like ammonia and 100% green hydrogen will also be usable in the future.

The use of alternative fuels such as SNG and biogas is now made even more relevant by rising prices and the falling availability of natural gas threatening security of supply. To ensure the growing availability of alternative fuels, MAN Energy Solutions is driving forward the power-to-X technologies for their production.

Retrofits for cleaner, more efficient, and more profitable operation

MAN Energy Solutions takes a life-cycle approach to engine design, with the intention of future-proofing your investment. This means our gas engines are easy to retrofit for alternative fuels. For example, MAN gas engines already in operation can be retrofitted for hydrogen admixture by upgrading the automation and adding adaptive combustion control sensors.

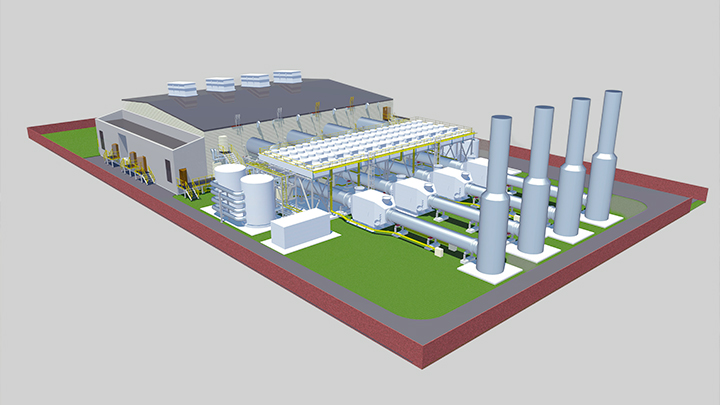

Explore our interactive

gas engine power plant

Take a 3D flight around a gas engine power plant with our interactive product experience. The model includes choices of basic equipment supply (ES), extended equipment supply with electrical and control (EC), and basic or extended engineering, procurement and construction (EPC).

Downloads

Continue reading

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.