A new study from MAN Energy Solutions’ experts looks at the most cost-effective paths towards green shipping

What’s the most effective and cost-efficient way to achieve the maritime energy transition by 2050? A new research paper from MAN Energy Solutions highlights the pathways to rapid sustainable shipping, finding that while energy efficiency measures need to be scaled, it’s dual-fuel engines and green fuels that will lead the way.

By Niels Anner

In 2023, the International Maritime Organization (IMO) reinforced its commitment to decarbonize shipping with the adoption of a revised Strategy on Reduction of GHG Emissions from Ships. While the strategy includes ambitious targets for net zero emissions around 2050, the IMO will not be releasing concrete measures to reach that target until 2027 – too late in an industry where the average lifespan of a ship is 25-30 years.

“There’s been widespread demand for stronger shipping regulation,” says Anders Kryger, Principal Strategist at MAN Energy Solutions. “But we need measures to determine the most economical and efficient ways for the industry to decarbonize.” To fill that gap, Kryger along with a team of experts at MAN Energy Solutions have written a new white paper outlining key steps to meet the IMO's revised reduction targets. The paper evaluates which technologies are available today and which ones will become the most promising in the future, highlighting the choices available to ship owerns in the coming decades.

A two-stroke dual-fuel engine running on synthetic fuels offers the most cost-effective and straightforward path to decarbonization.

The case for alternative propulsion technologies

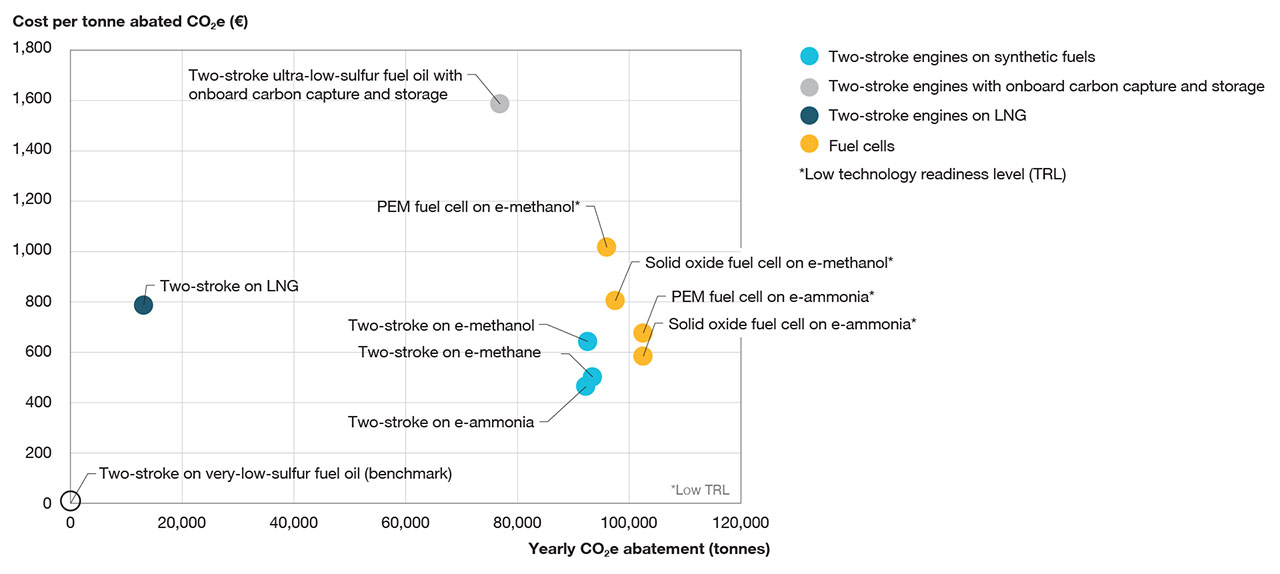

In the paper, Kryger and colleagues have evaluated CO2 abatement compared to fuel oil for various propulsion technologies and assessed associated costs, including those for onboard supply and storage systems, lost cargo space and fuel.

In an analysis of the well-to-wake GHG emissions of different fuels, the paper makes it clear that fossil-based fuels, even when combined with energy-saving devices (ESDs), are not sufficient to achieve net-zero. “This makes the development of other alternative propulsion technologies the first priority,” stresses Kryger.

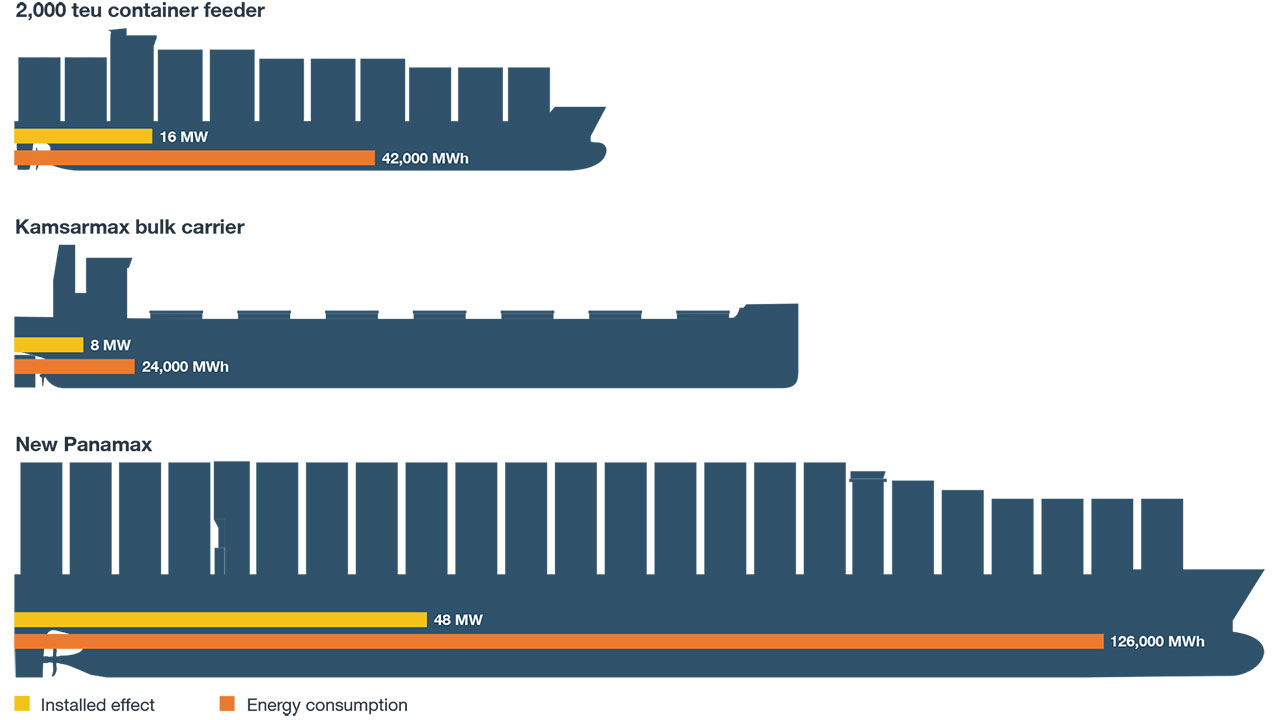

The propulsion options in the paper consist of two-stroke dual-fuel engines running on e-Methanol, e-Ammonia, LNG or e-methane, both with and without additional power take off (PTO), waste heat recovery and synthetic pilot oil injection. The effects of these technologies have been calculated for three high-volume merchant marine vessel types: a New Panamax container vessel, a 2,000 TEU feeder vessel, and a Kamsarmax bulk carrier.

The white paper examines the impact of decarbonization technologies on three vessel types with different installed effects (i.e. how many megawatts the engine generates) and different energy consumption. ©MAN Energy Solutions

The advantages of synthetic fuels

For all three vessel types, the picture is consistent, according to Kryger: “For large ships with high energy demand, a two-stroke dual-fuel engine running on synthetic fuels offers the most cost-effective and straightforward path to decarbonization.” E-ammonia and e-methanol, along with e-methane, are carbon-neutral or even carbon-free when produced with green hydrogen and renewable electricity.

On ships with high energy demand, e-ammonia has a slightly higher potential for emissions reduction and at a lower cost than e-methanol. For smaller merchant ships, e-methanol is advantageous because the increase in capital expenditure is limited compared to fuel oil. Fuel cells, says Kryger, once they are commercially available for larger ships, could reduce even more GHG emissions, “but at a much higher cost per tonne than a two-stroke engine.”

For the industry to embrace more complex and costly solutions, additional regulations and incentives will be needed.

“As a leading engine manufacturer, we’re ready to provide dual-fuel two-stroke engines operating on synthetic fuels,” says Dorte Kubel, Regulatory Affairs Manager at MAN Energy Solutions, "but to ensure that these fuels are sufficiently available for shipping around the world, the whole energy value chain has to decarbonize.”

Dual-fuel engines provide flexibility for the future

The availability of green fuels, particularly green hydrogen as their foundation, will be critical to the successful decarbonization of the maritime sector with dual-fuel engines. It's not a chicken-and-egg dilemma, the experts at MAN Energy Solutions say: Both technology and sufficient fuel quantities are necessary.

Dual-fuel methanol engines have already reached a Technology Readiness Level (TRL) 9, meaning the system has been proven in an operational environment. Dual-fuel ammonia engines are currently at TRL4, with the technology validated in a test engine setting, but are expected to reach TRL9 around 2025.

On Panamax vessel, two-stroke dual-fuel engines yield the most cost-effective abatement of CO2e compared to other propulsion technologies. ©MAN Energy Solutions

With more and more countries releasing national green hydrogen strategies and major shipping companies like A.P. Moeller-Maersk already ordering dual-fuel methanol engines, the momentum behind green hydrogen production continues to grow. However, production needs to be scaled up to an industrial level. In the meantime, says Kubel, dual-fuel engines capable of running on both diesel and synthetic fuels give ship owners the flexibility to make a gradual energy transition.

The impact of ESDs

Since green fuels are not yet available in sufficient quantities, ESDs are considered promising to rapidly advancing the reduction of emissions. The paper examines the impact of various ESDs, such as high-efficiency propellers, wind-assisted propulsion, air lubrication systems, exhaust gas recirculation and speed optimization.

Applying these measures can potentially cut CO2 emissions by 30 percent for container vessels, 45 percent for bulk carriers, 50 percent for tankers, and 60 percent for LNG carriers – under the assumption that all relevant technologies are integrated and speed is optimized. However, unlocking the full potential of ESDs seems out of reach.

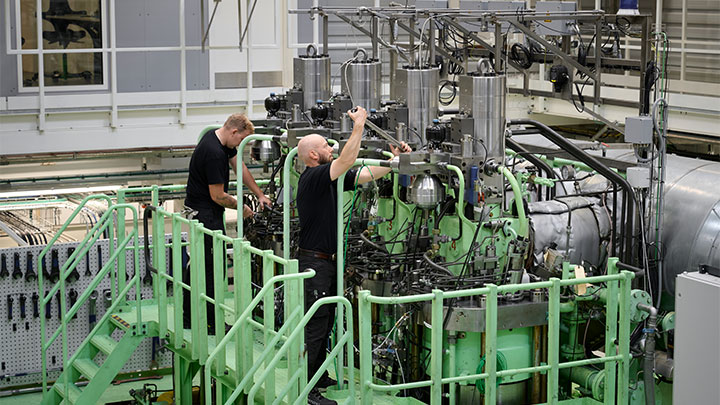

MAN Energy Solutions is developing future-proof two-stroke engines that can run on climate-neutral fuels such as green ammonia and methanol. ©Niels Busch

From the perspective of ship owners, certain solutions may be technologically feasible but not economically viable for retrofitting, according Kubel: “For the industry to embrace more complex and costly solutions, additional regulations and incentives will be needed, such as more detailed midterm measures from the IMO.”

If ESDs are not fully utilized, adds Kubel, the urgency to switch to low-carbon fuels is even higher. For example, a ship with a lifespan of 25 years contracted today must be able to operate at net zero by 2050. Therefore, newbuilds should be equipped with some alternative fuel capability with dual-fuel engines – in combination with ESDs – while existing ships need to consider retrofit options for ESDs and engines. This approach, the new white paper concludes, “will solidify and amplify as we move closer to the year 2050.”About the author

Niels Anner is an independent journalist based in Copenhagen, who writes on business, science, technology and society in Northern Europe.

Decarbonization technologies in merchant shipping

In the research paper, our MAN Energy Solutions’ two-stroke experts assess the GHG effect of energy saving technologies on merchant marine ships and how far the technologies can take the ship types toward compliance. The paper explores the pathways to fast implementation and scaling of decarbonization technologies in merchant marine shipping.

Explore more topics

-

Retrofitting engines for greener fuels

Retrofitting engines for greener fuels is a “no regret” move in the maritime energy transition.

-

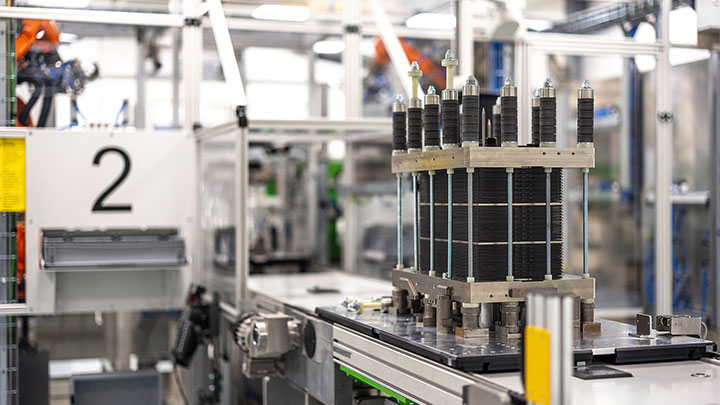

Opening Quest One hydrogen Gigahub

Quest One opens new Gigahub factory in Hamburg, Germany, for the serial and automated production of electrolysis stacks.

-

Lifecycle Upgrade Grand Cayman

MAN PrimeServ is turning 25-year-old engines into highly efficient modern types at a power plant on the Cayman Islands. Learn more about our Lifecycle Upgrades.