Why use off-line oil filtration systems from C.C.JENSEN?

Off-line filtration or kidney loop filtration delivers similar- or better-quality oil compared to a conventional separator. C.C.JENSEN offers new technology in filtration systems that revolutionizes the way lube oil is maintained on two- and four-stroke engines across all fuel types. As a global authorized partner of C.C.JENSEN, we are offering the CJC engine lube oil filtration systems, tested by MAN PrimeServ, to prolong the service life of your engine, reduce maintenance costs, and improve environmental performance.

Benefits of installing a C.C.JENSEN lube oil filter:

Main benefits compared to a conventional separator

- Up to 60% less oil consumption on four-stroke engines

- Up to 20% less oil consumption on two-stroke engines

- 99% lube oil sludge reduction

- 97% fuel savings compared to a conventional separator, contributing to the CII*

- Extended oil and component lifetime by 2-10 times

- No preheating of oil is required

Additional benefits:

- ROI under 1 year

- Cost-efficient and easy maintenance

- Off-line system does not require the main system to shut down for maintenance or filter changes

- Continuous cleaning 24/7/365

- Controlled oil replacement on schedule

*Carbon Intensity Indicator

Explore the benefits Stolt-Nielsen achieved with Engine Lube Oil Filters

After installing 10 Engine Lube Oil Filters, Stolt-Nielsen, a global leader in chemical tanker transportation, conducted extensive efficiency research to evaluate financial and operational benefits. This research is based on measurable factors, such as lube oil quality, filter consumption, and purifier running hours, along with feedback from the crew working directly with the filter units.

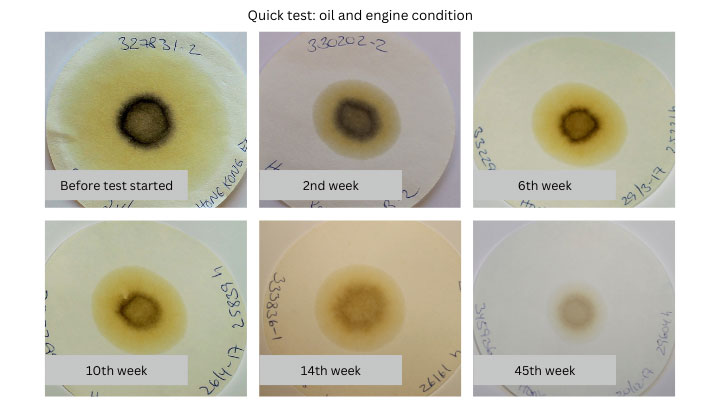

Quick test: efficient oil care

The quick test shows that the lubricating oil was heavily contaminated with dust, metal abrasion, and other particles before and at the beginning of the test period. Oil aging signs and high water content were detected. Thermal load on so-called hot spots (e.g. bearings) and particles from component wear (copper, iron, aluminum) accelerate the degradation of the base oil as well as of the additives and thus the oil aging process.

With the efficient oil care from the C.C.JENSEN filtration system, particles, water, oil aging products, as well as acid compounds were permanently removed. The oil cleanliness throughout the test period has been significantly improved.

Our services:

- Support and advice on choosing the right filtration system

- Retrofit installations, new installations, spare parts, and replacement filter insertions with short delivery times.

- Return on investment (ROI) calculation to evaluate your savings.

Calculate savings and return on investment (ROI) for your vessel

We offer a complementary report that analyses your vessels and demonstrates what can be expected after installing the C.C.JENSEN oil filtration system. The report will accurately show savings to be made with respect to fuel, oil sludge production, and CO2 emissions. Together with ROI calculator, the report will summarize the full business case. Please don’t hesitate to contact our experts for more information, or directly fill out the form below.

Download nowCatch up on the latest MAN ExpertTalk session!

We explored the future of lube oil maintenance for two- and four-stroke engines, regardless of fuel type. Hosted by Andre Douwenga (Product Manager, MAN PrimeServ) and Steffen Dalsgaard Nyman (Corporate Trainer, C.C.JENSEN), the informative session gives insights into CII improvement, savings, and ease of operation that the C.C.JENSEN lube oil filtration systems achieve.

Cost comparison between the centrifuge and CJC Lube Oil Filter

Main engine information

Main engine:

Stroke: two-stroke

Power rating: 9,000.00 kW

Quantity: 1

Centrifuge information:

Flow: 4,468 l/h

Quantity: 1

By using CJC Lube Oil Filter instead of a conventional centrifuge:

- Operational expenses are reduced by 52%

- Carbon footprint is reduced by 94%.

AUX engine information

AUX engine:

Stroke: four-stroke

Power rating: 1,150.00 kW

Quantity: 4

Centrifuge information:

Flow: 959 l/h

Quantity: 2

By using 4 CJC Lube Oil Filters instead of a conventional centrifuge :

- Operational expenses are reduced by 53%

- Carbon footprint is reduced by 98%

Why MAN PrimeServ?

- Global authorized partner of C.C.JENSEN

- A single global point of contact for the service of engines, turbochargers, and other auxiliary equipment

- Original equipment manufacturer (OEM) supply chain

- MAN PrimeServ warranty. Terms and conditions apply

- Minimal flight and hotel costs for field engineers since our service centers offer total geographic coverage

Find your nearest service center

In addition to C.C.JENSEN filtration technology, MAN PrimeServ provides service for your critical equipment and components in the engine room, regardless of OEM.

Are you in need of urgent service on your fleet or plant? Contact your nearest service center.

Resource Hub

Contact our MAN PrimeServ experts

For non-urgent requests, don’t hesitate to reach out. Our experts will happily provide advice and support.

Explore more topics

-

Omnicare - 3rd party services

PrimeServ Omnicare is a a one-stop service solution that provides complete support for all your equipment – engines and turbomachinery – regardless of manufacturer.

-

Marine & Power

PrimeServ Omnicare provides third party maintenance of complete fleets and plants using a single supplier for all services.

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.