Reducing cat fine-related damages in engines

Combating Abrasive Particles

Abrasive particles, such as cat fines, cause wear when they enter the combustion chamber of two-stroke & four-stroke engines. Here, they may get trapped between sliding surfaces such as the piston ring and cylinder liner, or the piston ring and ring groove. An example of particle trapping can be seen in Figure 1, where cat fines are embedded in the soft graphite lamellas in the cylinder liner surface. Cat fines enter the fuel during the refining process. They are found both in heavy fuel oil (HFO) and in some of the new types of fuel with less than 0.1% S (ULSFO).

MAN's Recommendations on Cat Fine Limits

The latest marine fuel standard specifies a maximum of up to 60 ppm Al + Si in the fuel (ISO 8217). This high level would cause extremely high wear in the combustion chamber. MAN’s recommendation is to keep this under 15ppm. Read more in the Service Letter.

Product variants

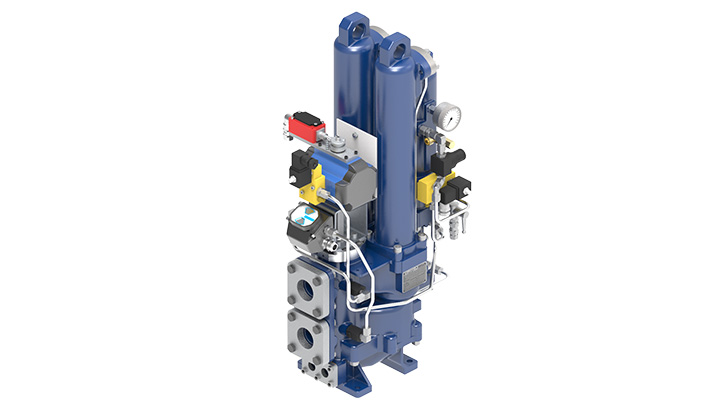

BOLLFILTER Automatic Type 6.7

| Range of application | Heavy fuel oil, diesel oil, lubricating oil |

| Max. operating pressure | 16 bar |

| Max. operating temperature | 160 °C |

| Housing material | EN – GJS – 400 -15 |

| Nominal width of connection flanges | DN 40, DN 65 or DN 80 |

| Filter candle type / mesh type | Cylindrical screw-in candles or star candles with woven mesh |

| Grade of filtration | 3 µm to 150 µm |

| Cleaning | Sequential reverse-flow backflushing, assisted by compressed air |

| Backflushing control | Differential pressure-dependent or time-dependent |

BOLLFILTER Automatic Type 6.64

| Range of application | Lubricating oil, diesel oil, heavy fuel oil, coolants, emulsions, industrial wash liquids |

| Differential pressure resistance | Up to operating pressure |

| Operating temperature | Up to 150 °C |

| Housing material | Nodular cast iron / Nickel lining on request |

| Grade of filtration | Up to 10 µm abs. |

| Filter candle type/ mesh type | Cylindrical screw-in candles or star pleated candles with woven mesh or fiber felt |

| Cleaning method | Sequential reverse-flow backflushing, assisted by compressed air |

| Backflushing control | Differential pressure-dependent or time-dependent |

3 reasons to choose Boll & Kirch

backflush filter

Fuel Cost Savings

By reducing the backflush volume, our solution significantly lowers fuel consumption, leading to substantial cost savings.

Extended Service Hours

Extend the service life of fuel injection nozzles from as low as 400 to at least 8000 hours, ensuring long-lasting performance and reliability.

Improved Engine Reliability

Enhance engine reliability and increase component service life, ensuring your equipment runs smoothly with minimal interruptions.

Locate the nearest service location for 360° support

PrimeServ offers comprehensive support for all engine room components, no matter the manufacturer. Find your nearest service location and learn more about our Omnicare portfolio today!

Contact our MAN PrimeServ experts

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.