Turnaround Solutions

We take care of your entire turnaround

Turnarounds on rotating equipment trains are always challenging projects. Short time schedules, complex products and high number of different suppliers require a professional project management. MAN Energy Solutions supports you as a strategic business partner during this important phase. Our excellent global field service network and qualified pool of suppliers, as well as our extensive technical know-how and our certified project managers help you to successfully plan and execute large-scale turnarounds for your machinery trains.

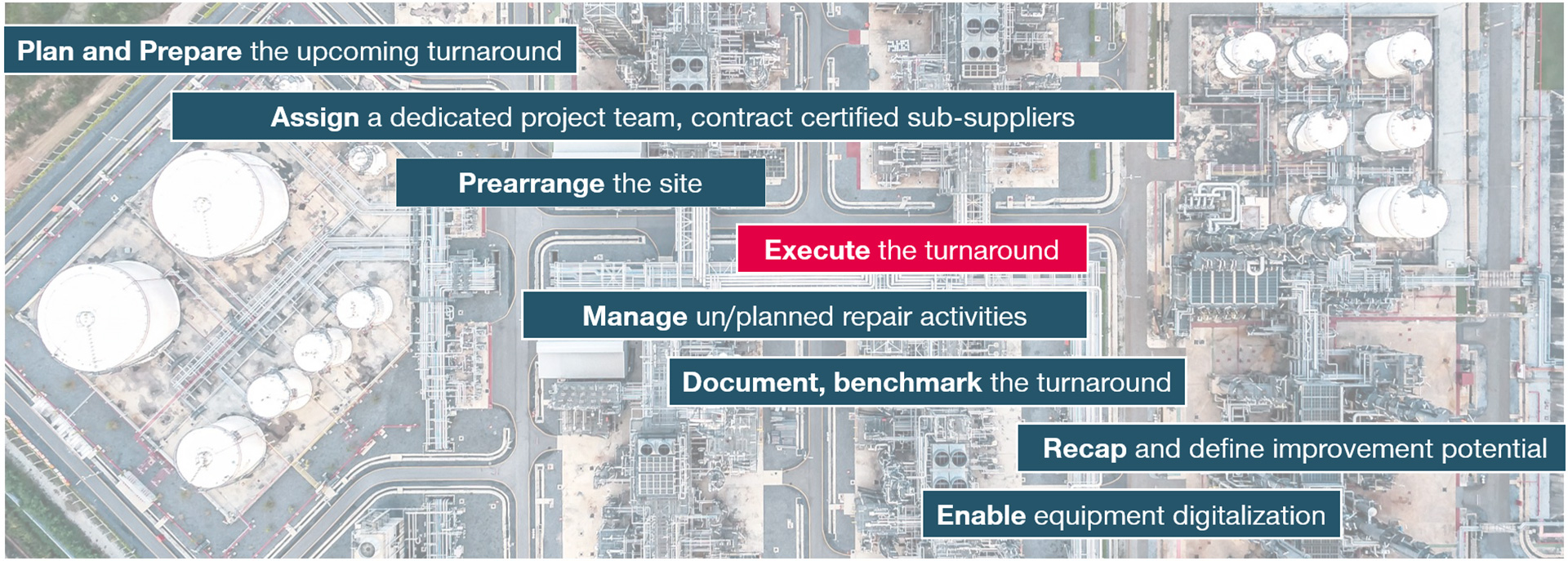

How the Turnaround is being managed by MAN Energy Solutions

MAN PrimeServ takes care of your entire turnaround scope in one contract. Benefit from the planning, accountability and implementation of your entire turnaround. MAN as your main contract partner handles all different equipment in the scope and contracts and coordinates all sub-suppliers.

How to benefit

- One-stop service

- Single point of contact

- One responsible and accountable partner

- One single interface, one contract

- Integrated optimized Turnaround schedules and Increase uptime

- High safety and OEM quality standards

The MAN PrimeServ One-Stop shop

Core Machines & Periphery

- Maintenance on MAN and non-MAN turbomachines and their drivers

- Inspection and repair of auxiliary components, e.g. condenser, oil unit or gearbox

Project Management

- Optimized planning to minimize downtime, professional project management by seamless cooperation of all parties involved

- Supplier management incl. proven and certified supplier network

- HSE, Quality and Logistics Management

Engineering

- All engineering disciplines, turbomachinery repair & upgrade competences and reverse engineering resources in house

Download product information

Increase availability, improve safety, strengthen sustainability, and boost capacity and efficiency of your turbomachinery: identify the upgrade solutions matching to your operational priorities, download product information, and make more informed decisions driving your overall business strategy. Explore where our upgrade solutions can take you!

References

Steel Mill

Steel Mill Turnaround Solution

OEM: Siemens, DEMAG

Equipment types: steam turbines, axial compressors

Scope of supply:- Repair of two trains composed of steam turbine and axial compressor, including control panel and electric system upgrade, filter house modernization and other peripherals

Challenge:

- Re-engineering

- Size and weight of equipement

- Covid-19 scenario

Oil refinery

Oil refinery

OEM: General Electric, Mitsubishi, Elliott/Ebara, Turbimaq, NG, Cameron

Equipment types: steam turbines, axial and centrifugal compressors

Scope of supply:

- Overhaul of MAN steam turbine (99MW)

- Inspection of non MAN generator and auxiliaries

- Project management

Challenge:

-

Very time critical job

-

More than 50 FSE– no subcontracting was permitted for entire scope

-

100% local content

-

Covid-19 scenario

Fertilizer Plant

Fertilizer Plant

OEM: MAN Energy Solutions, Siemens, AEG Kanis, Nuovo Pigone

Equipment types: steam turbines, barrel and horizontal split-line centrifugal compressors

- Major overhaul of 13 casings across 3 trains including refrigeration units, air and synth trains

Challenge:

-

Very time critical job

-

Different OEM equipment

-

Covid-19 scenario

Power Generation

Power Generation

Scope of supply:

- Overhaul of MAN steam turbine (99MW)

- Inspection of non MAN generator and auxiliaries

- Project management

Challenge:

-

Overhaul of entire steam turbine driven

generator train (99MW)

Aiming to optimize your spare parts management?

Wondering how to mitigate availability risks and ensure the reliability and performance of your machine trains? Whatever your challenge, talk to us. MAN PrimeServ has a long track record of meeting spare part needs. Our global network of service centers is available to work out the best solutions to support your business.

Explore more topics

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.