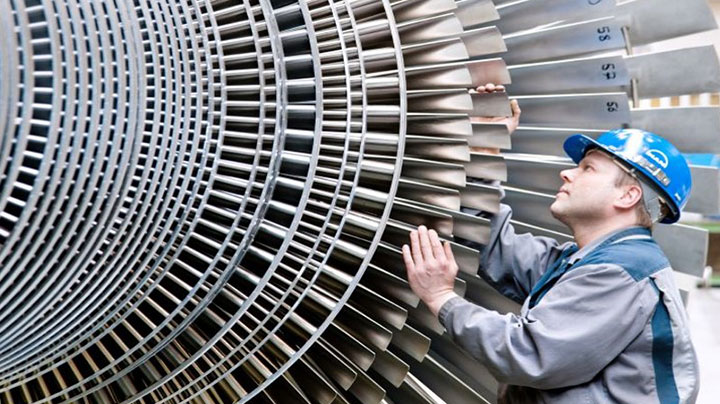

Field service for turbines and compressors

Boost operational availability

MAN PrimeServ field service offers end-to-end coverage for operations industrial. Its global network of service centers provides 24/7 OEM-quality field services.

Benefit from greater flexibility, faster turnarounds, and services available anytime, anywhere

Field servicing is crucial to maintaining the reliability and efficiency of turbines, compressors, and expanders. And, we know, every single hour counts.

MAN PrimeServ’s global field services give you short response times and access to the resources

and in-depth knowledge of a leading OEM wherever you are. Localized service engineers and specialists ensure you enjoy maximum flexibility, whether you need qualified assembly personnel on-site or veteran technicians to supervise your staff or subcontractors.

MAN PrimeServ offerings for field services leverage augmented reality and digital technology such as PrimeServ EyeTech and virtual commissioning for control system upgrades.

How you benefit:

- Certified Competence Management System (CMS)

- OEM expertise with continuous multi-stage professional training and qualification concept based on German standards

- Increase the availability of your equipment

- Leverage next-generation tools, diagnostics, and advanced technology

- Benefit from fast response times and a global service network

- Rent – or purchase – field service containers customized to your needs

The MAN PrimeServ field service portfolio

MAN PrimeServ is the service solution provider for the entire

MAN Energy Solutions portfolio as well as third-party rotating equipment.

We offer you a full spectrum of services, solutions, and technologies, guaranteeing higher availability, efficiency and capacity.

- On-site technical and operational support

- Preventive maintenance

- Supervision of work

- Performance of inspections, revisions, and repairs

- Implementation of modernizations on compressors, ancillaries, and control systems

- Thorough planning of workforce, spare parts, and tools

- Planning leverages data-driven insights

- Completion of turnkey installations, including large turnarounds

PrimeServ SolutionAdvisor - your goals, our service

Overhaul of turbomachinery trains at one of the largest and most complex inland refineries in Europe

Collaborating on a major refinery turnaround project involving 50 contractors, 29,000 planning hours and 820,000 work hours, MAN PrimeServ handled the overhaul of seven turbomachinery trains and related services.

| Customer: | OMV Austria |

| Customer type: | Refinery |

| Application: | Petrochemical production |

| Location: | Schwechat, Austria |

| Processing capacity: | Approx. 10 million tons of crude oil per year |

Work scope of MAN PrimeServ: | Overhaul of seven turbomachinery trains and both their auxialiary and secondary systems; reworking the surface of two turbine casings exhibiting gaps along their split line |

References

Overhaul

Lump Sum Overhaul of various Turbomachines during Refinery Turnaround in 2017

Scope of services

-

Necessary replacement of rotating blades Stage 201

-

Customer has no spare rotor

Others

-

Refurbishment of 2 turbine casings / welding / re-machining in MAN PrimeServ workshop in Oberhausen.

-

Re-engineering of the turbine split line bolts from heating system to hydraulic system

-

New delivery and installation of turbine insulations

-

Control-system upgrade

General:

-

In order to reach the tight schedule MAN rendered in total 24.000 Field Service man-hours with 100 MAN personnel in Day- and Nightshift.

-

Overhaul was succesfully completed within the anticipated time frame, quality and specifications with no site incidents.

General Overhaul

General overhaul in 2019

Location: Singapare

Scope of services

-

General overhaul of condensing steam turbine and booster compressor within Supervision services

General:

-

Detailed project planning along with customer prior to the shutdown

-

On-Site machining, local welding on stator parts and casings, necessary repairs works have been coordinated and managed by MAN PrimeServ

-

Work have been succesfully completed in less than the given 24 calendar days by customer

Turn-Key Turnaround

Large Turn-Key Turnaround in 2019

Scope of services

-

Performance of a large turnaround within 50 calendar days

-

Turnaround of 8 machine trains

- 2 Crack gas compressors driven by steam turbines

- 2 Ethylene compressors driven by steam turbines

- 2 Propylene compressors driven by steam turbines

- 1 Booster (multishaft) compressor driven by an electrical motor

- 1 Charged gas compressor driven by steam turbine

Others:

-

Engineering services

-

Complete supply of spare parts

-

Modifications of components

-

Site- & project management

- MAN PrimeServ acted as a solution provider

- During the turnaround MAN rendered in total 21.000 manhours

- 53 Field service engineers worked in day- & nightshift

Lump Sum Overhaul

Lump Sum Overhaul of Ethylene cracker in 2015

Scope of services

-

Performance of a general overhaul within 28 calendar days

-

General overhaul of 4 steam turbines total drive power 50 MW

-

General overhaul of 5 radial compressors

General:

-

Overhaul of the machine upper casings in the MAN PrimeServ workshop in Oberhausen.

-

Planning / Execution / Transport have been coordinated and managed by MAN PrimeServ

-

The overhaul was succesfully performed with over 40 Field service engineers and 10.950 rendered manhours in two shifts.

Operational improvement

Operational Improvement

The performance of the steam turbine shows an increase of 2 MW in the coupling performance at about 2kg/s lower steam consumption.

Location: Domenican Republic

Scope of services

-

Turnkey overhaul of steam turbine

-

On-Site machining of rotor and stator labyrinth seals

Benefits:

-

Increase of steam turbine performance of 6%

-

Improvement of lower steam consumption

-

Coordination of all site activities byMAN PrimeServ Field Service Coordination

-

Control of overall shutdown planning by MAN field service site management

Continue reading

Do you want fast access to on-site expertise and a quick emergency response to ensure the availability of your rotating equipment?

The on-site expert teams of MAN PrimeServ provide field services, from preventive maintenance to shutdown resolution – whenever and wherever you need it. Our field service teams help you keep your equipment operational, shutdowns short, and maintenance costs low.

Explore more topics

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.