Modularity reduces the CAPEX of carbon capture

From cement to chemicals, from power generators to refineries: Large carbon footprints are a challenge for heavy industries. Carbon capture, utilization, and storage (CCUS) lowers emissions, reduces spending on CO2 certificates, and helps companies demonstrate social responsibility. You can even benefit from CO2 by turning waste into a resource or using steam from carbon capture as process heat.

Our modular approach reduces project complexity and lead times, mitigates risks, and keeps down CAPEX. MAN CCUS features modular compression solutions for all available capture technologies.

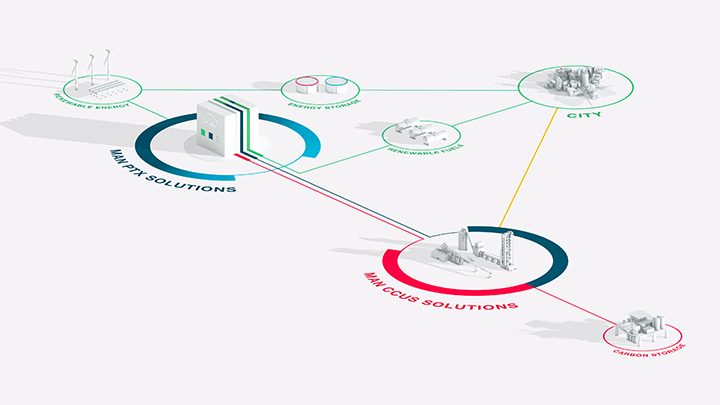

The rationale of carbon capture

CO2 is typically captured at industrial plants and compressed for easier transport instead of being released into the atmosphere. It can then be stored underground or used as feedstock for other industrial processes. In this way, CCUS reduces your carbon emissions and the CO2 you produce can become a commodity.

Modular components for the carbon capture value chain

Every MAN CCUS solution is different but, thanks to modularization, we can answer the individual needs of different types of industrial plants. We offer best-in-class modules in every area of the CO2 value chain. For capture, we have RG compressors with heat recovery for amine gas treatment. The same RG compressors are used for transportation via CO2 pipelines, for CO2 liquefaction, or in sequestration. We also provide further process components and turbo solutions such as closed water-cooling loops and process solutions with heat and power recovery.

Having a set of pre-designed compressor modules allows us to adapt our engineering more flexibly and rapidly to your needs. This improves project lead times, reducing acquisition costs.

High quality

High quality makes us the world market leaders in CCUS compression business for high flow and high pressure. You can count on more than 30 years’ experience, with more than one million hours’ operation and over 200 million tons of compressed CO2.

Increased efficiency

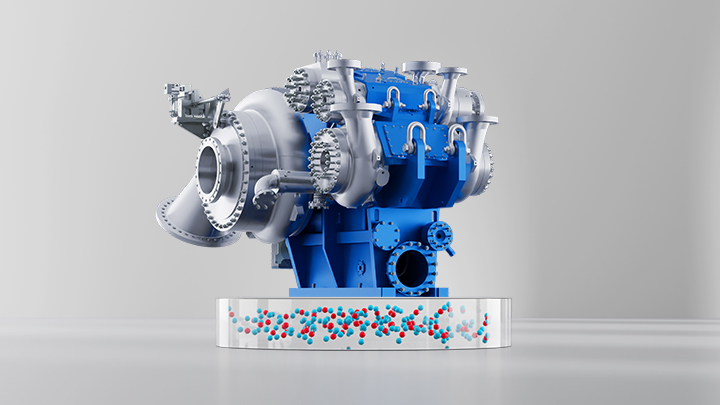

Our multi-shaft integrally geared compressors feature selectable impeller speed, optimized pinion speeds and different compressor sections in one casing. This ensures the highest efficiency and adaptability to your specific needs.

Reduced costs

Modularization reduces CAPEX and OPEX without compromising on efficiency. It reduces complexity at your plant, meaning you need less manpower and infrastructure. Modular CCUS reduces lead times, reduces production and testing times, and simplifies installation. Furthermore, heat recovery from the compressor can save up to 50% heat energy, and power recovery from expansion saves another 30%.

Easy maintenance

Standardized components mean easier maintenance. Our MAN PrimeServ service engineers can provide preventive maintenance, assist in troubleshooting, and get your facilities up and running in no time.

Better availability

Reducing specifications can lead to increased reliability and easier maintenance of compressor systems. Standardized components are easier to replace and maintain, as they are more readily available and require less specialized knowledge to service.

Compressor expertise

MAN Energy Solutions provides the leading compression technology and expertise necessary for CCUS, such as displacement and turbo compressors. MAN oil-free screw-type compressors combine the advantages of turbo and reciprocating compressors, with volume flows of 200-20,000 m3/h and discharge pressure up to 52 bar. The MAN RG integrally geared compressor has suction flow rates of up to 500,000 m3/h and maximum discharge pressure up to 250 bar.

MAN RG Compressor: Key for decarbonization of hard-to-abate industries

Decarbonizing cement

Cutting cement emissions is not just ecologically responsible but makes economic sense. Our modularized packages with standardized components are readily available and simple to integrate, shortening lead times by up to 30%, mitigating risks, and keeping down CAPEX.

Decarbonizing chemicals

Using pre-designed compressor modules allows us to integrate carbon capture into your chemical plant more flexibly and rapidly. Our modular components meet the flow and pressure requirements of different CO2 emitter sizes and transportation modes (gaseous, liquid, or supercritical).

Decarbonizing power

Carbon capture provides a solution to rapidly reduce emissions from fossil-fueled power plants. Our flexible compressor modules quickly adapt to your conditions and our pre-assembled units reduce on-site installation times. Modularization reduces CAPEX without compromising on efficiency.

Decarbonizing refineries

CCUS can help to rapidly reduce the carbon footprint of a refinery. We use standardized components for modularized compressor technology within the purification process to improve energy consumption and life-cycle costs.

Upcoming MAN Events and Expert Talks

-

CCUS

Champion of CCUS: MAN integrally geared compressor solutions

MAN ExpertTalkWatch our online webinar about a key element in our approach to carbon capture, utilization, and storage: the integrally geared MAN RG compressor – the champion of CCUS!

Why do we call the RG compressor our champion of CCUS? Learn more about it in with our experts Mauricio Ramirez and Cristina Cantarino.

Go to recording -

CCUS

MAN modularized carbon compression solutions

MAN ExpertTalkFrom cement to chemicals, from power generators to refineries: large carbon footprints are a challenge for heavy industries. Tightening emission caps and growing decarbonization incentives are pushing large CO2 emitters to adopt carbon capture solutions quickly.

MAN has the answer with its efficient, reliable, modularized, and well proven CO2 compression technology. Our modular approach reduces project complexity and lead times, mitigates risks, and keeps down CAPEX. Watch our webinar focusing on the latest innovations in modular carbon capture.

Go to recording

Read more

Contact our experts

Unlock your sustainable future with MAN CCUS

At MAN Energy Solutions, we're dedicated to helping you embrace a sustainable future. Our modular CCUS solutions can reduce your carbon footprint and achieve your environmental goals without the need for emission certificates. Our experts will be happy to help you put together the perfect system solution for your requirements.

Explore more topics

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.