Powering the maritime energy transition

Minimizing the impact of shipping on the climate and the environment is a crucial contribution to reaching the global climate targets. One of the ultimate goals is carbon neutral or carbon free transportation.

Currently, worldwide maritime transport emits around 3% of the global greenhouse gas (GHG) emissions. The International Maritime Organization (IMO) has set a target of net-zero CO2 emissions from shipping by or around 2050. An ambitious goal that requires technological changes in the industry.

MAN Energy Solutions is leading the way in sustainable two-stroke engine innovation. We have a large portfolio and proven track record of dual-fuel engines that run on methanol, methane (LNG), LPG, or ethane. Following the successful start of single-cylinder tests of our MAN B&W two-stroke ammonia engine in 2023, we began full-scale engine tests in 2024. Ultimately, we are aiming to enable the delivery of the first ammonia engine, the MAN B&W ME-LGIA to a shipyard in 2025. As newbuild or retrofit, it will be a valuable addition to the existing MAN B&W two-stroke dual-fuel engine portfolio and will meet future market demands for green ship propulsion.

Ammonia – a new chapter in two-stroke engine history.

Proven two-stroke engine design

The ammonia two-stroke engine is based on the proven and trusted MAN B&W ME-LGI engine concept. It will be available as a newbuild engine or as a retrofit option for existing electronically controlled ME-C engines. The engine is currently under development at our Research Centre Copenhagen.

The development also includes safety measures such as ammonia containment systems, sensors, system ventilation and double-walled piping. In July 2023, we achieved the first combustion with ammonia on the two-stroke research engine, with highly promising data on the stability of the combustion process. During November 2024, the full-scale engine testing commenced, and will focus on, among other parameters, combustion and emissions, engine-tuning, atomizer testing and control-system verification. This is provisionally set to continue until mid-2025.

Watch the work.

Ammonia engine: key benefits

Energy density and efficiency

Ammonia can be used as an energy carrier of sustainable hydrogen and is carbon free. The two-stroke ammonia engine technology development aims for a small percentage of just 5% pilot oil at 100% load based on L1 rating*. The remaining 95% of the energy will be provided by ammonia while supplying you with high power, energy density, efficiency and extremely low emissions.

Ammonia can be used as an energy carrier of sustainable hydrogen and is carbon free. The two-stroke ammonia engine technology development aims for a small percentage of just 5% pilot oil at 100% load based on L1 rating*. The remaining 95% of the energy will be provided by ammonia while supplying you with high power, energy density, efficiency and extremely low emissions.

*Performance values indicated refer to energy fraction for L1 rated engines operating at 100% load point in Tier II mode. Actual values may vary depending on engine rating and load conditions.

Carbon- and sulphur-free

Ammonia is carbon- and sulphur-free and gives a clean combustion. Green ammonia as a fuel for shipping has the potential to become the sustainable future fuel choice, especially due to the expected lower production cost compared to other e-fuels such as e-methanol and synthetic natural gas.

Ammonia is carbon- and sulphur-free and gives a clean combustion. Green ammonia as a fuel for shipping has the potential to become the sustainable future fuel choice, especially due to the expected lower production cost compared to other e-fuels such as e-methanol and synthetic natural gas.

Retrofits

The future installation of an ammonia combusting engine can be adapted to the customer. For example, as a dual-fuel, modular retrofit solution for existing electronically controlled engines. Talk to our experts about the best solution for your company.

The future installation of an ammonia combusting engine can be adapted to the customer. For example, as a dual-fuel, modular retrofit solution for existing electronically controlled engines. Talk to our experts about the best solution for your company.

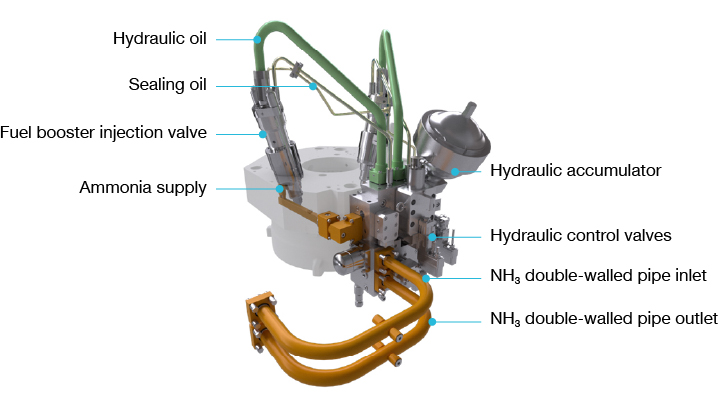

Injection system for ammonia

The MAN B&W ammonia engine design philosophy

Ammonia mode

A small pilot flame is needed to start ammonia combustion. Initial tests were conducted with 10-15% pilot as a first step. The R&D target is around 5% pilot oil at 100% load for L1-rated engines.*

We target for the same heat rate as “fuel

oil mode”. The ammonia engine concept will be based on the Liquid Gas Injection engine concept, which is well known from the existing methanol and LPG-fueled MAN B&W two-stroke dual-fuel engines.

*Performance values indicated refer to energy fraction for L1 rated engines operating at 100% load point in Tier II mode. Actual values may vary depending on engine rating and load conditions.

Fuel oil mode

We target identical performance as a conventionally fueled diesel engine.

Ammonia auxiliary systems

The auxiliary systems provide additional support to the MAN B&W ammonia engine and together ensure safe and efficient combustion. The ammonia catch system and the addition of absorbers make sure that no ammonia will be vented to the atmosphere above 5 ppm at our Research Centre Copenhagen.

Selective catalytic reduction technology

To reduce emissions of nitrogen oxides and to fulfil IMO Tier III emission regulations, engines from MAN Energy Solutions have been equipped with selective catalytic reduction (SCR) technology for many years.

The SCR system using ammonia was introduced in the 1990s in four bulk carriers.

It is an after-treatment process, where NOX formed during combustion is removed from the exhaust gas in a catalytic reduction. Additionally, the SCR unit will be utilized to remove any ammonia slip from the exhaust.

Pending the outcome of the first engine test results, an increase in SCR volume and ammonia consumption may be necessary to achieve compliance in Tier III mode.

Contact us

Talk to our experts for ammonia engines

You want to know more about our two-stroke ammonia engine and how it can suit your goals? Our global network of dedicated engineers will help you find the perfect solution for your business. Start your change process now and reach out to us today.

Download the paper and learn more about the ammonia engine

Related content

-

Ammonia engine testing

Engineers are developing a two-stroke, dual-fuel ammonia engine that can reduce a ship’s emissions to zero.

-

The case for two-stroke ammonia engines

Why newbuild and retrofit ammonia engines are key for the maritime energy transition.

-

Related news

-

Monday, February 17, 2025

MITSUI E&S Commences Full-Scale Ammonia Testing

First commercial ammonia two-stroke engine takes next step towards market entry -

Thursday, January 30, 2025

Full-Scale Ammonia Engine Runs at 100% Load

Two-stroke ME-LGIA engine testing in Copenhagen passes further milestone on path to commercial market entry -

Tuesday, December 3, 2024

Full-Scale Ammonia Engine Opens New Chapter

Two-stroke engine testing in Copenhagen marks important milestone on path to dual-fuel ME-LGIA development -

Tuesday, October 22, 2024

Ammonia-Powered Engine to be Developed for Medium-Speed Marine Applications

MAN Energy Solutions launches ‘AmmoniaMot 2’ research project with industry partners and research institutes

MAN ExpertTalk: Update on MAN B&W ammonia engine development

Having completed more than 12 months of testing on a single cylinder running on ammonia, the full-scale engine testing started at Research Centre Copenhagen in November 2024.

Tune in for the recording of out MAN ExpertTalk to learn more about this major milestone in the development of new two-stroke technology.

You can look forward to hearing more about our progress and learnings, the design of the safety systems for fuel handling as well as ammonia auxiliary systems.

This MAN ExpertTalk is hosted by Christian Ludwig with presentations by subject matter experts Nikolaos Kourtidis and Ian Kumaraswamy.