Enabling a scalable energy transition

The MAN B&W ME-LGIM two-stroke dual-fuel engine can run on methanol as well as conventional fuels. Specifically designed to meet the needs of the maritime industry, it is a versatile and scalable solution that is suited to a wide range of vessel types. Simple handling, storage, and bunkering of methanol, combined with relatively simple auxiliary systems and the potential to be carbon-neutral, makes it an attractive option for meeting decarbonization targets.

Proven two-stroke methanol engine design

Available either for newbuilds or for upgrading existing conventional fuel vessels, this engine represents a proven, refined engine design based on over 600,000 running hours on methanol alone. Methanol produced from renewable sources is an attractive marine fuel option due to its low carbon intensity. An engine using green methanol can even provide carbon-neutral propulsion.

Key benefits

A new design for efficient methanol combustion

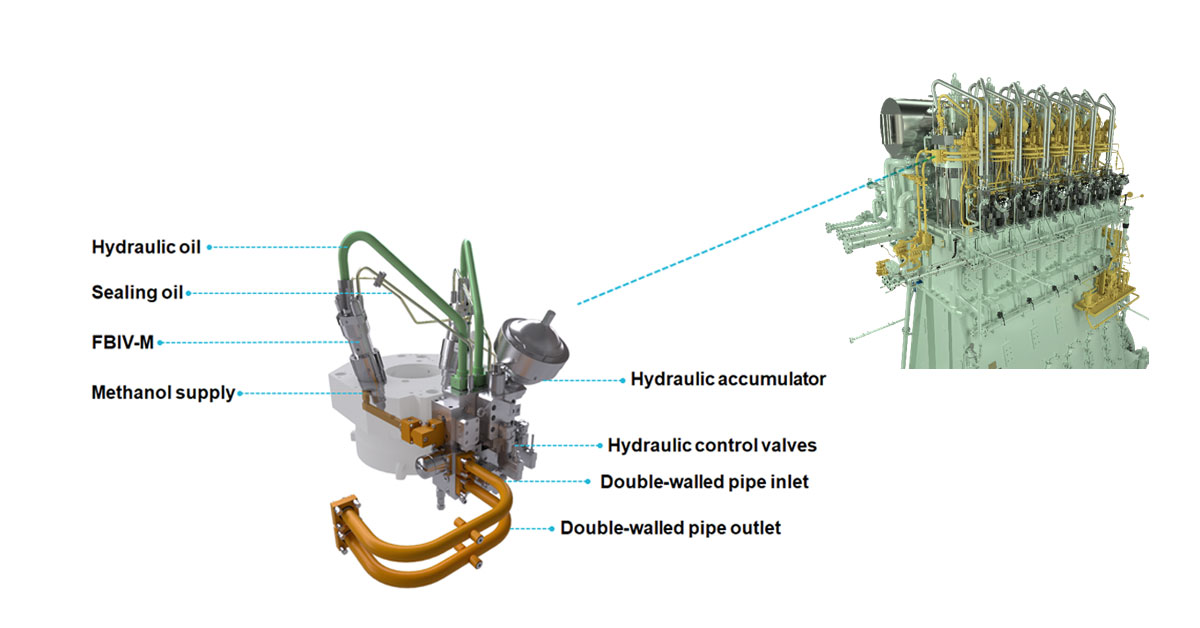

The ME-LGIM engine has inherited well-known components of our standard two-stroke diesel engine, like the ME-GI dual-fuel engine. Beneficial features of the standard MAN B&W two-stroke diesel engine have been retained. This illustration highlights methanol components and pipes that have been added to the cylinder top for methanol combustion.

The use of methanol as fuel type supports cost-effective vessel designs.

Moving together into a sustainable future

Learn more about the MAN B&W ME-LGIM engine

Continue reading

-

MAN B&W ME-LGIMpdf, 404 KB

Related products

-

-

MAN L21/31DF-M and MAN L27/38DF-M

Discover our methanol-fuelled small-bore engines: MAN L21/31DF-M and MAN L27/38DF-M.

-

Methanol Dual-Fuel Two-Stroke Engine

Mærsk's bold move to focus on large methanol-powered container ships is an important step in the decarbonization of the shipping industry.

Related News

PrimeServ SCR Retrofit Makes Cruise Ship Tier III-Compatible

MAN Energy Solutions’ after-sales division, MAN PrimeServ, has completed a retrofit aboard the ‘Ambience’, a vessel belonging to Ambassador Cruise lines, managed by Bernhard Schulte Cruise Services. The scope of the project covered the installation of SCR (Selective Catalytic Reduction) systems, while two of the ship’s four MAN 8L58/64 engines replaced their NA57/T turbochargers with modern MAN TCA 66 units.

The order came about when Ambassador overtook the Ambience with the intention of offering cruises in the key Norwegian Heritage Fjord market with its exacting Tier III emission standards.

Olaf Gunia, Head of PrimeServ Hamburg, said: “This retrofit really establishes Ambassador’s green credentials within the cruise segment and the SCR solution is performing well with a NOx removal rate of 93%. Increasingly, we are receiving similar requests from cruise and ferry operations that wish to become sustainable without the need for mandated industry legislation.”

Bernd Siebert, Head of Retrofits & Upgrades, MAN PrimeServ, said: “This entire project proved challenging owing to – among other factors – the long cold lay-up of the ship due to the covid-19 pandemic, and the tight timeframe for completion. Happily, our work on the Ambience has optimised the interaction between the newly installed SCR system, turbochargers and engines and the vessel is now Tier III-compatible and fit for service in one of the globe’s most pristine, natural environments.”

SCR technical considerations

MAN’s SCR system is the greenest solution available on the market with the highest operational readiness and safety. The SCR will be available from just 15% engine load, enabling clean operation, also during slow-sailing in the fjords as well as close to port and populated areas.

The fully modular SCR solution has also been fully integrated into the Ambience’s engine-control set-up. With its closed-loop system and a weather station that uses environmental data, the NOx-reduction rate is maximised and ammonia-slip minimised to just 10 ppm, comparable to that of a car. Low ammonia slip is not just good because ammonia is a greenhouse gas and affects the climate, but also because it reduces urea consumption enabling the urea-tank size to be minimised.

Documents

-

PR Ambience_EN

Contact

Nils Søholt

Trade Press Marine

Group Communications & MarktingMAN Energy SolutionsTeglholmsgade 412450 Copenhagen SVDenmark

nils.soeholt@man-es.com t +45 33 85 26 69Available languages

- DE ·

- EN

Get notified about press releases

Alternative fuels for your two-stroke powered vessel: Ammonia, methanol and methane in focus

Watch the recording of our latest MAN ExpertTalk on alternative fuels for large merchant marine vessels. Get insights into the most promising marine fuels of the expected future fuel mix for two-stroke vessels, namely ammonia, methanol and methane.

You can also look forward to hearing about the latest product developments and applications as well as reasons why these fuels have the potential to offer a straightforward path for the future maritime energy transition.