Future proof engines for offshore wind vessels

More wind farms, bigger turbines, rougher locations: demand for renewable energy is stimulating growth in construction of wind parks at sea. Environmental responsibility demands that we minimize the carbon footprint associated with both installation and operation. The answer is a new class of wind farm installation vessels with clean, efficient engines that can cope with complex tasks in harsh conditions. We have drawn on our extensive experience in the offshore sector and we have future-proofed our engines for green fuels. Here you will find engines you can build on.

Wind, waves, and clean energy

The vessels that transport, install, and maintain wind turbines must live up to high environmental standards. To meet the goal of carbon neutrality, vessels need reliable engines that are clean and highly efficient: operators’ reputations depend on them. As the wind farms migrate further offshore in search of strong winds, the sea conditions become tougher.

Offshore wind engine portfolio

The methanol-ready MAN 32/44CR and MAN 175D engines are reliable, efficient, low-emission designs. These engines are perfectly suited for specialist wind farm applications such as wind turbine installation vessels (WTIVs) and wind foundation installation vessels (WFIVs) or for general offshore support vessel applications such as service operations vessels (SOV) and commissioning service operation vessels (CSOVs).

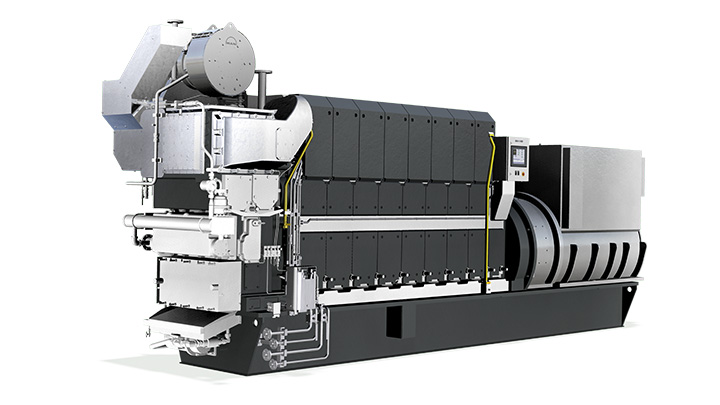

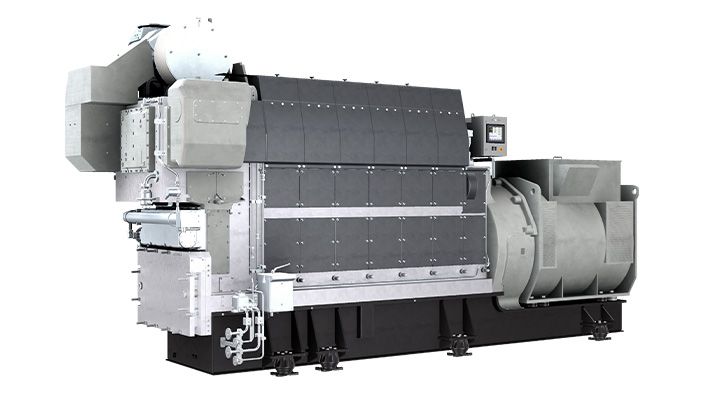

Methanol-ready MAN 32/44CR

The MAN 32/44CR brings together the most advanced large-engine technologies, including the MAN common rail system, high-efficiency turbochargers, variable valve timing and state-of-the-art control systems. These advantages are future-proofed by the availability of the methanol retrofit.

Available as propulsion engine or GenSet.

Methanol-ready MAN 175D

The most powerful high-speed engine on the market meets emissions standards without compromising on efficiency or performance. Thanks to its compact size and clear-cut design, it is easy to integrate and easy to operate and maintain. Long TBOs and low fuel consumption ensures the lowest OPEX and reduces emissions. A methanol dual fuel retrofit will be available from 2026.

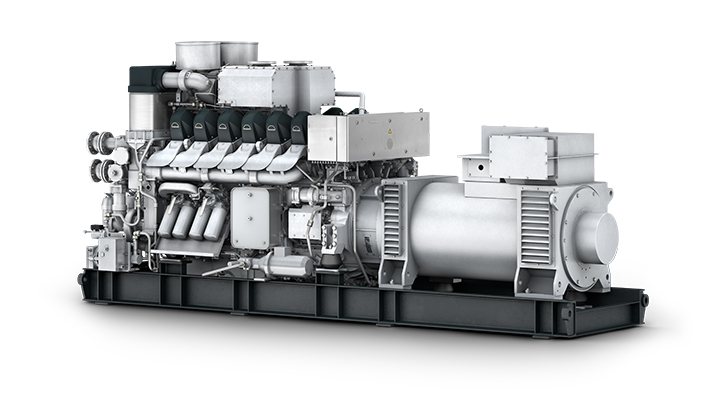

MAN 175D GenSet

Packing the latest technology into minimal space, the MAN 175D GenSet is characterized by a clear-cut design, flexible ship integration, simple operation, and straightforward maintenance. Its modular design allows it to meet all the challenges of today’s offshore applications.

MAN L21/31 Mk2

MAN L21/31 Mk2 offers reliable power,

stable operation and the possibility to operate this engine on conventional

fuels as well as biofuel oils. Optimized engine design with improved fuel

efficiency delivers cost efficiency during its entire life cycle. This engine

represents a safe investment for your offshore wind vessel.

Methanol-fuelled MAN L21/31DF-M

Methanol-fuelled MAN L21/31DF-M is a compact and reliable engine which offers fuel flexibility and possibility to lower greenhouse gas emissions. It can be operated on methanol, conventional fuels as well as most biofuel oils. With its outstanding load-step capabilities and extremely long time between overhauls (TBOs), it is a perfect future-proof solution suitable for powering your offshore wind vessel.

MAN L27/38 Mk2

Powerful MAN L27/38 Mk2 delivers improved competitiveness and reliable operation which make it a solution suitable for most offshore applications. This engine can run on conventional fuel types as well as biofuel oils and offers cost efficiency during its entire life span. The methanol version of this engine (MAN L27/38DF-M) is already in development.

MAN ExpertTalks

-

Energy & Storage

From source to solution: Methanol’s missing link in energy transition

MAN ExpertTalkE-methanol is produced using renewable energy. This often comes from offshore wind turbines, which are installed by specialized vessels, which are powered by MAN methanol engines. These are just some of the links in the methanol value chain, but they show how MAN Energy Solutions can bring together suppliers and consumers of methanol. We also provide links through CCS, hydrogen electrolysis, and methanol synthesis.

References

Hybrid Propulsion Package for Cable-Laying Vessel Features 4 × MAN 175D GenSets

VARD, one of the major global designers and shipbuilders of specialised vessels,, has ordered 4 × MAN 12V175D-MEM GenSets in connection with the building of a new purpose-built, cable-laying vessel (CLV) for NCT Offshore, the Danish subsea specialist. The GenSets will form part of the vessel’s diesel-electric DP2 propulsion system, which also includes a hybrid battery package.

Florian Keiler, Head of High Speed, MAN Energy Solutions SE, said: “This exciting project is just the latest in the rapidly-growing offshore-windfarm market. Happily for us, the 175D is strongly represented within this segment where it is commonly the engine of choice for owner and yard alike. In such a green environment-driven sector, the 175D’s inherent fuel efficiency and low emissions make it an ideal propulsion solution, either as a standalone or – as in this case – as part of a hybrid package. It is also the engine with the lowest total cost of ownership in the market with a small environmental footprint.”

The high-speed 175D GenSets will each come accompanied by compact MAN SCR (Selective Catalytic Reduction) systems. Furthermore, MAN Energy Solutions states that the engines have the lowest lube-oil consumption on the market.

Featuring state-of-the-art DP2 positioning and seakeeping systems, the CLV will be equipped with an intelligent power system solution for improved sustainability – encompassing batteries, switchboards, and shore connection – that will reduce fuel consumption and increase operability. The vessel will feature a bollard pull in excess of 60 tons, while maximum transit speed will exceed 14 knots.

About the MAN 175D engine

MAN Energy Solutions has developed the MAN 175D engine range to supplement and complete its product portfolio in the maritime sector. Available in three variants of 12-, 16- and 20-cylinders, the engine is available with an output ranging from 1,500 to 4,400 Kilowatts and is optimised for propelling ferries, offshore support ships, tugs and other working vessels. Other market areas, such as superyachts, planing yachts and naval marine applications are also served by additional engine variants.

The 175D is also an extremely eco-friendly engine, having been designed from the outset for low fuel consumption, coupled with compliance to the latest exhaust-gas-emission standards and considering as well future-fuel requirements where it is already approved for operation on biofuels, such as FAME and HVO.

*Graphical rendering of the newbuilding cable-laying vessel (picture courtesy VARD). The 95-metre CLV has single-cabin accommodation for 60 persons and will be capable of providing turn-key array cable T&I scopes of work for large-scale, offshore renewable projects*

Documents

-

PR NCT-Vard 175D_EN

Contact

Nils Søholt

Trade Press Marine

Group Communications & MarktingEverllenceTeglholmsgade 412450 Copenhagen SVDenmark

nils.soeholt@everllence.com t +45 33 85 26 69Available languages

- DE ·

- EN

Get notified about press releases

Find out how we can help you

Get in touch with our offshore vessel experts and discover how we can create an efficient and future-proof solution for your wind farm installation vessels.

Continue reading

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.