The transition to renewables is reshaping the role of traditional power plants. Our experts weigh in on the trends

In a market committed to renewable energy, what does the future look like for conventional power plants? From hydrogen-ready engines to dispatchable services, MAN Energy Solutions experts Michael Fiedler and Martin Wiedemann look at the major trends in the industry.

By Florian Bayer

“As more and more renewables are added to the grid, there’s an amount of uncertainty for power plant operators,” says Michael Fiedler, Senior Business Development Manager, Power Segment at MAN Energy Solutions.

“Where for decades baseload applications have been the bread and butter of power plants,” adds his MAN colleague Martin Wiedemann, Senior Business Development Manager, Power Segment, “we now see a demand for fast, dispatchable applications that support decarbonization and stabilize the grid.”

With decades of experience in industry, Wiedemann and Fiedler have been engaged in the massive energy transition the power sector is undergoing, with Fiedler specializing in future fuels like hydrogen and ammonia for power generation, and Wiedemann in emission reductions using new technologies. Both agree that conventional power plants still have a significant role to play in enabling the success of the transition. But which systems provide the best support? And what will power plants require in the future?

The need for balancing services requires advanced power plants with rapid startup times and high operational flexibility

1. A new role for power plants: balancing services

“Balancing energy production will be the essential ability in the future,” says Martin Wiedemann. As inherently variable renewable energy sources like wind and solar become more prevalent, balancing becomes crucial to maintaining grid stability. This involves real-time adjustments of power output to level out frequency deviations in the grid and ensure that electricity supplies meet demand at all times. Without these services, a mismatch of high power demand and low energy availability leads to outages.

In Europe alone, policies are aiming to reduce greenhouse gas emissions by as much as 55 percent by 2030 (compared to 1990 levels), and for complete carbon neutrality by 2050 – with similar targets around the globe. “You may have started out with a baseload plant running natural gas,” says Fiedler, “but as renewables increase in the grid, you’ll see your running hours decrease. But even gas-fired plants contribute to decarbonization by balancing the grid – this is ultimately what allows us to expand renewables at all.”

2. Fast reactions: putting flexibility into power systems

“The need for balancing services requires advanced power plants with rapid start-up times and high operational flexibility,” says Wiedemann. Operational flexibility is a power systems’ ability to respond to changes in demand. This includes the use of smart technologies that measure and react to fluctuations in real-time, minimizing bottlenecks and optimizing usage, but for power plants it means operating at low-minimum loads and having short start-up and shut-down times as well as high ramp-up rates.

As early as 2030, our engines will be able to run entirely on hydrogen.

‘There’s also a lot of interest in co-generation plants, but in summer you don’t need the heat,” says Fiedler, “you just need the energy. So, it’ s no longer the case that a power plant has just one operating mode.” Moreover, a wide range of operating modes means increased fuel efficiency and an overall reduction in costs.

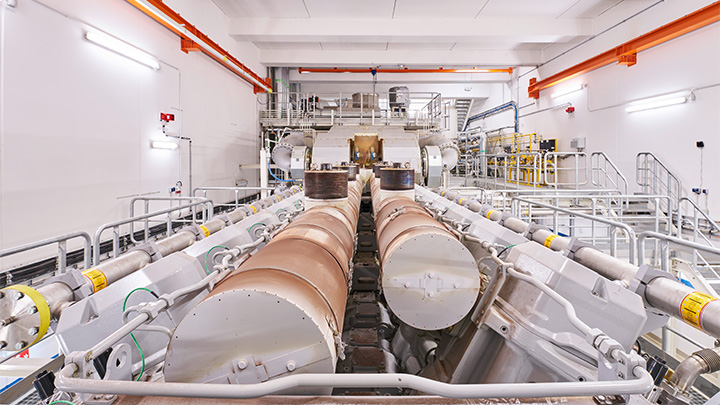

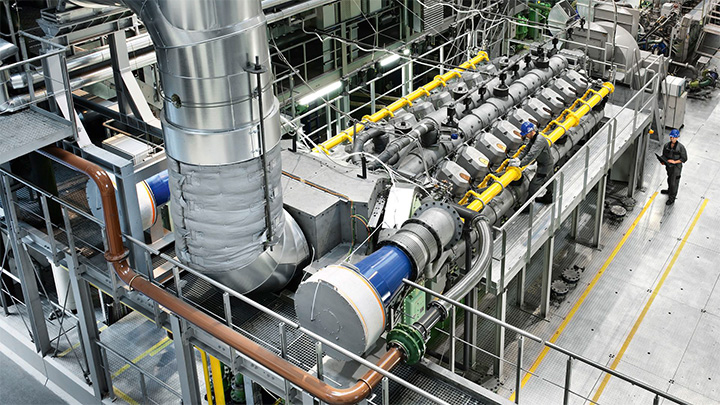

3. Versatility: modern engines for power generation

In support of balancing services and operational flexibility, Wiedemann and Fiedler are seeing a trend toward having decentralized engine-driven power plants leading the transformation as opposed to large turbines. “Modern engines are designed for better emission control and can use low-carbon fuels such as hydrogen,” says Fiedler, “making the most out of whatever fuel sources are available without a change in output.”

Also, unlike turbines, power plants running on engines excel better in applications that require rapid response times. The MAN 35/44G, for example, can go from start-up to full load in less than three minutes, supplying the first MW to the grid within 30 sec. And engines offer better scalabity and perform at high ambient temperatures, ensuring operation in hot climates without additional capacity. Wiedemann is already seeing large, engine-driven power plant projects, upwards of 200 megawatts, for balancing services in Australia, the US and Germany.

4. It bears repeating: efficiency, efficiency, efficiency

Efficiency should be a continual process: optimizing plant operations with equipment upgrades, software and tools and implementing the most current best practices. Efficiency minimizes losses, saving on fuel costs and reducing emissions. And as Fiedler points out, efficiency should be included in the design of any new power plant, optimizing the use of energy, for example, with combined heat and power.

Engines already operate at high efficiency levels and have a significant cost advantage over turbines: Adding a smaller unit (like a 10-megawatt engine) is less costly and more flexible as you have the option to add additional units that run in accordance with the power demand compared to scaling up with one large turbine of 50 megawatts and more which is less efficient and limited in meeting changing load demands. Changes in demand can be addressed more accurately with various modular engine units and without producing excess energy.

5. Future proofing: building hydrogen-ready plants

In recent years, the transition towards hydrogen is gaining momentum. Power plants are now being designed to be “hydrogen-ready”, meaning they can switch to hydrogen fuel as it becomes more available. This involves not only the capability to burn hydrogen but also the infrastructure to handle, store, and transport hydrogen.

“Our focus at MAN is on cleaner future fuels such as hydrogen for power generation, ensuring our engines are ready for these transitions.” The company’s newest engines have been designed to handle up to 25 percent hydrogen blending with natural gas – equal to the planned levels of hydrogen incorporation into Europe’s natural gas grid. “As early as 2030,” adds Fiedler, “our engines will be able to run entirely on hydrogen.”

Not only hydrogen, also other fuel types have potential as they become available and commercially viable. Fiedler specifically mentions ammonia, which might play a role for certain applications in the future. He also emphasizes the development of dual-fuel engines that can operate on e-methane or biofuels and diesel, offering more transitional flexibility.

The future of resilient energy landscapes

Power generation is undergoing significant transformation towards renewables. This change is driven by the need for efficiency, flexibility, and sustainability. Balancing services, operational flexibility, and hydrogen-ready technologies are the decisive requirements for the future. Modern engine power plants are ensuring to meet current and future energy demands while minimizing their environmental impact. As these technologies continue to rapidly develop, a fact about which Fiedler and Wiedemann have no doubts, they will play an increasingly significant role in shaping a resilient and sustainable energy landscape.

About the author

Florian Bayer is a freelance journalist based in Vienna, Austria, where he has written for Die Zeit Online, Der Standard, and the Wiener Zeitung.

Fueling decarbonization

At MAN Energy Solutions, we make engines that run on future fuels, such as green hydrogen and its derivatives including synthetic natural gas (SNG), green ammonia, and green methanol. We also provide the means of producing the net-zero fuels themselves. We are ready to help you decarbonize – now.

Explore more topics

-

The latest-generation wind turbine installation vessel

A new wind turbine installation vessel with a customized-engine configuration lets offshore wind contractor Cadeler transport and lift more powerful turbines in even rougher locations – and they’re saving emissions while they are at it.

-

Hapag Lloyd LNG container vessel

Hapag-Lloyd’s new LNG-powered containership cuts emissions by a quarter immediately and by 95 percent with green methane

-

Heidelberg Materials: First CCS plant for cement industry

The first CCS facility for cement production in Brevik, Norway, is paving the way for carbon-neutral industrial processes.