To plug in safety gaps, you have to identify them first

Ensuring robust levels of safety is both social responsibility and vital to your business strategy. But safety challenges are becoming increasingly complex. They evolve and multiply as your assets age. How do you reliably detect safety gaps? And, how do you identify safety investments that are not only efficient and cost-effective but will drive the sustainable success of your organization?

Operational safety needs a proactive approach

From eliminating hazards in the workplace to promoting safe behavior, safety is a mindset vital to your business success. Strong operational safety contributes to higher and more robust availability. A zero-incident reputation and effective safety programs can improve workplace satisfaction and boost retention. Low operational risk is instrumental in preventing reputational losses – a growing strategic concern in a connected world where a few keystrokes can shatter a brand’s global reputation.

The key is to be proactive. To put solid safety processes in place, start with a fact-finding mission at the heart of your application – where people interact with machine trains, engines, and equipment. Tap into the safety expertise of OEM partners intimately familiar with your assets, application, and market. Build on their insights to craft a strategy that fits your operational safety goals.

Ensuring machine protection optimizes availability

Machine safety is a critically important issue across all sectors – oil & gas, chemicals, power generation, and marine. Safety gaps are risk drivers for organizations as a whole. But protecting machines and safety-relevant processes in increasingly complex environments is a multidimensional challenge.

From remote monitoring to upgrades, choosing the right investments requires you to stay on top of the latest in R&D, monitor evolving certifications and standards, and track the safety options at your disposal. It’s an on-going effort.

There are ways to outsource the worrying. Your concerns overlap with those of your OEM. Benefit from the fact that your safety concerns are their safety concerns. The bonus? They know your engines, machine trains, and auxiliary equipment inside out.

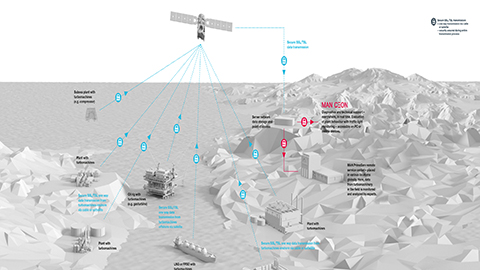

Cybersecurity encompasses all layers of an organization

As industries make great strides in bringing smart and connected applications to life, leveraging digitalization and automation comes with a host of new challenges and requirements. Whether it is a hack attack from outside or a simple unprotected USB port on-site, vulnerabilities are everywhere. The problem all cybersecurity strategies face: To be effective, they must consider all levels, from component to plant, from network to organization. The dilemma is an abundance of choices. Cybersecurity solutions come in every size and shape. Some harness data, accelerate connectivity, and come with built-in layers of security. Others take the form of component upgrades with newer, more safety-aware, design iterations. Some solutions sterilize specific vulnerabilities. The challenges: to identify the solutions that best meet your criteria – and reliably assess their ROI.

At MAN PrimeServ, we give you more than just the latest service solutions

As market conditions and regulations change around you, MAN PrimeServ helps you minimize your risk and maximize your potential – for today and tomorrow

An intimate understanding of challenges to operational availability has made us a leading service solutions provider for organizations across different key sectors. As a trusted partner, MAN PrimeServ monitors the market and legislative trends in the industries it serves, from maritime transport to the oil and gas industry, from power generation to the process industry. This allows us to not only design the services you need today but to anticipate the solutions you need to meet the availability challenges of tomorrow.

Our solutions build on our OEM expertise

Benefit from our holistic understanding of your application and the sector your organization competes in, from maritime transport to the oil and gas industry, from power generation to the process industry.

How you benefit

- Ensure safety awareness and the best possible protection of your employees with OEM-level training

- Rely on our global expertise as a contributor to international standards bodies. We evaluate your compliance with the latest safety laws, standards, and regulations and offer actionable recommendations

- Benefit from a holistic approach to assessments, which includes reviewing threshold values for maximum safety and optimized availability

- Leverage comprehensive data security layers in solutions for connected assets

A holistic approach to protecting your data

We offer effective cybersecurity solutions and concepts tailored to your individual needs and performance goals. Ensuring data protection and safety against tampering and unwanted access, our solutions are easy to integrate and apply the highest industrial cybersecurity standards. Our in-depth defense concept addresses all security layers: component security, network security, plant security, and organizational security. Our consultants quantify the performance gains of recommended solutions and the return on investment.

Explore PrimeServ Assist, remote monitoring with built-in cybersecurity

Detect gaps early

Robust safety management systems and procedures are crucial in preventing incidents from affecting availability and performance. Remote monitoring is instrumental in detecting vulnerabilities early: Smart algorithms enable condition-based – even predictive – maintenance to prevent those incidents before they occur. Inspections are another tool in your safety toolbox. They complement monitoring solutions identifying safety issues remote monitoring solutions can’t see. Combined, they ensure high long-term safety levels.

Robust safety management systems and procedures are crucial in preventing incidents from affecting availability and performance. Remote monitoring is instrumental in detecting vulnerabilities early: Smart algorithms enable condition-based – even predictive – maintenance to prevent those incidents before they occur. Inspections are another tool in your safety toolbox. They complement monitoring solutions identifying safety issues remote monitoring solutions can’t see. Combined, they ensure high long-term safety levels.

In risk assessments, we assess risks and safety levels and issue recommendations to help you protect your assets and fulfill your operator obligations. Our experts collaborate closely with you to take the safety needs and business goals of your organization into account when we make recommendations.

Explore how periodic inspections help to detect maintenance requirements

Discover how PrimeServ Assist Online Monitoring protects your assets

Leverage OEM safety expertise

All safety aspects of their products are of vital concern to original equipment manufacturers (OEM). As a party that shares your interest in the optimal operational and functional safety of your assets, MAN PrimeServ is uniquely positioned to serve as a trusted strategic partner. Our focus is on futureproof safety solutions: Our customers benefit from exclusive access to the latest design iterations of MAN ES products that implement the latest safety standards.

As an OEM, we have the capabilities and the holistic understanding of applications needed to ensure robust machine operation. We optimize parameters for maximum safety while minimizing unscheduled downtimes and improving overall availability.

Find out how valve diagnostics help to ensure availability, efficiency and safety

Discover TUR safe – the next generation of SIL certified turbomachinery protection systems

Build a culture of safety

As the OEM manufacturer and designer of turbines and compressors, engines, and rotating equipment, we share our knowledge and insight with technicians and operators. We help you build a holistic safety culture that protects your people and your investment.

Get the full picture of your safety options

MAN PrimeServ supports you in tackling individual safety challenges and discovering how to identify – and minimize – potential hazards. A substantial portion of our safety solutions is also available for engines and equipment from third-party manufacturers. Contact us to learn more.

Explore more topics

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.