Cultivating a greener future

Against the background of the world’s growing demand for food, the energy transition adds important challenges for the fertilizer industry, setting environmental sustainability goals which raise the need for efficient, cost-effective production methods. By embracing these obstacles as opportunities, you can pave the way for a prosperous tomorrow, where responsible stewardship of our planet goes hand in hand with nourishing a flourishing world.

We’ll help you transform your business

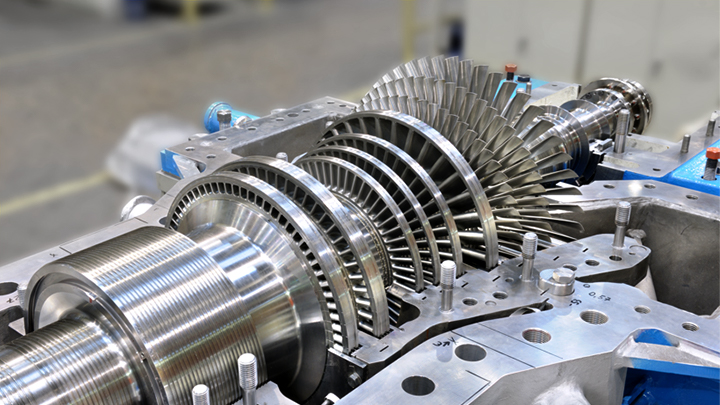

With MAN PrimeServ, you can address the fertilizer sector's two main goals: decarbonization and increased production. We are experts in transforming existing equipment and giving new life to your processes for unparalleled efficiency and sustainability. We can help you switch to green and blue ammonia production, implement waste heat and energy recovery, raise efficiency, and lower emissions. Our revamps increase production in new and existing plants. We push innovation and use digital solutions to avoid unplanned shutdowns.

.jpg?sfvrsn=fc4c8c70_4)

A world of solutions

If you want to boost your overall process, increase your fertilizer production, decarbonize your plant or ensure that your production keeps running, we have specific solutions. For example, we can run dynamic simulations to identify efficiency gaps, add a hot gas expander to your HNO3 production line, or use your waste heat for heat pumps. We can replace CO2 inline compressors with integrally geared compressors (~ 20% capacity increase with the same power consumption). We can also add carbon capture to your fertilizer plant. And, natural, we revamp and retrofit turbomachinery.

A partner around the world

Our global network of specialists and repair shops can help you master the challenges of the energy transition with customized service solutions that increase efficiency and capacity, lower emissions and improve availability. PrimeServ Omnicare is a one-stop service solution providing support for all your equipment regardless of manufacturer: whenever and wherever you need it you have access to the expertise of the industry’s most trusted specialist. You can rely on our long-term service agreements, digital services, consulting, and remote field services.

References

MAN PrimeServ has long-standing experience in serving the fertilizer industry. Here is a selection of recent projects.

New rotor for nitric acid plant

|

Scope of supply |

New rotor with 5 new impellers and corresponding stationary parts |

| Challenge | Original VWR715 design is unique |

| Solution | State-of-the-art, high-efficiency, high-performance impellers were used to meet today’s power rating expectations. |

| Key data |

|

Onsite repair of compressor train

|

Scope of supply |

Onsite repair of the compressors train. |

| Challenge | Deteriorated mechanical condition of LP and HP compressors, which required shipment of the compressors and equipment to the factory for intensive repair (long downtime). |

| Solution | Onsite planning and execution of the major overhaul and repair with all required tools and personnel (21) enabled the shortest downtime. 8.5% efficiency enhancement has been recognized after the TA. |

| Key data |

|

Digital LTSA for tailor-made operation

|

Scope of supply |

LTSA + PrimeServ assist contract for a complete machine train. |

| Challenge | Customize the machine train maintenance plan to optimize and increase production. |

| Solution | Remote monitoring and support plus inspections for a comprehensive understanding of the machine train’s condition. |

| Key data |

|

Control system upgrade

|

Scope of supply |

Control system upgrade. |

| Challenge | Obsolete control system, anti-surge protection not up to date, surges caused blades failure in 2019. |

| Solution | Upgrade with logic/software optimization (state-of-the-art ASC, optimization of trip concept, performance maps as per current site conditions) and upgrade of OVS system. |

| Key data |

|