Efficiency on the path to net zero

Like every other industrial sector, the pulp and paper industry is striving to decarbonize, driven mainly by regulatory pressure and customer expectations. In Europe, the official goal is carbon neutrality by 2050. In pulp and paper production, energy usage is primarily driven by the need to produce heat: drying pulp, paper, and tissues accounts for about 70% of the energy used in the industry. When industrial heat pumps are used to produce the steam necessary for a drying process, they apply electricity from renewable sources to waste heat streams from these drying processes. Steam-generating heat pumps are a simple and proven technology. They can decarbonize the energy supply, improve energy efficiency, and reduce plant energy costs.

The best steam heat pumps for pulp and paper

Large pulp and paper producers usually require a range of heat and steam systems for different types of pulp, tissue, and paper products. MAN Energy Solutions has built up decades of experience in implementing energy-efficient solutions such as the vacuum blowers and steam turbines required in the pulp and paper production processes. We can take on large, complex projects with a minimum of disruption and promise long-term reliability backed by comprehensive service.

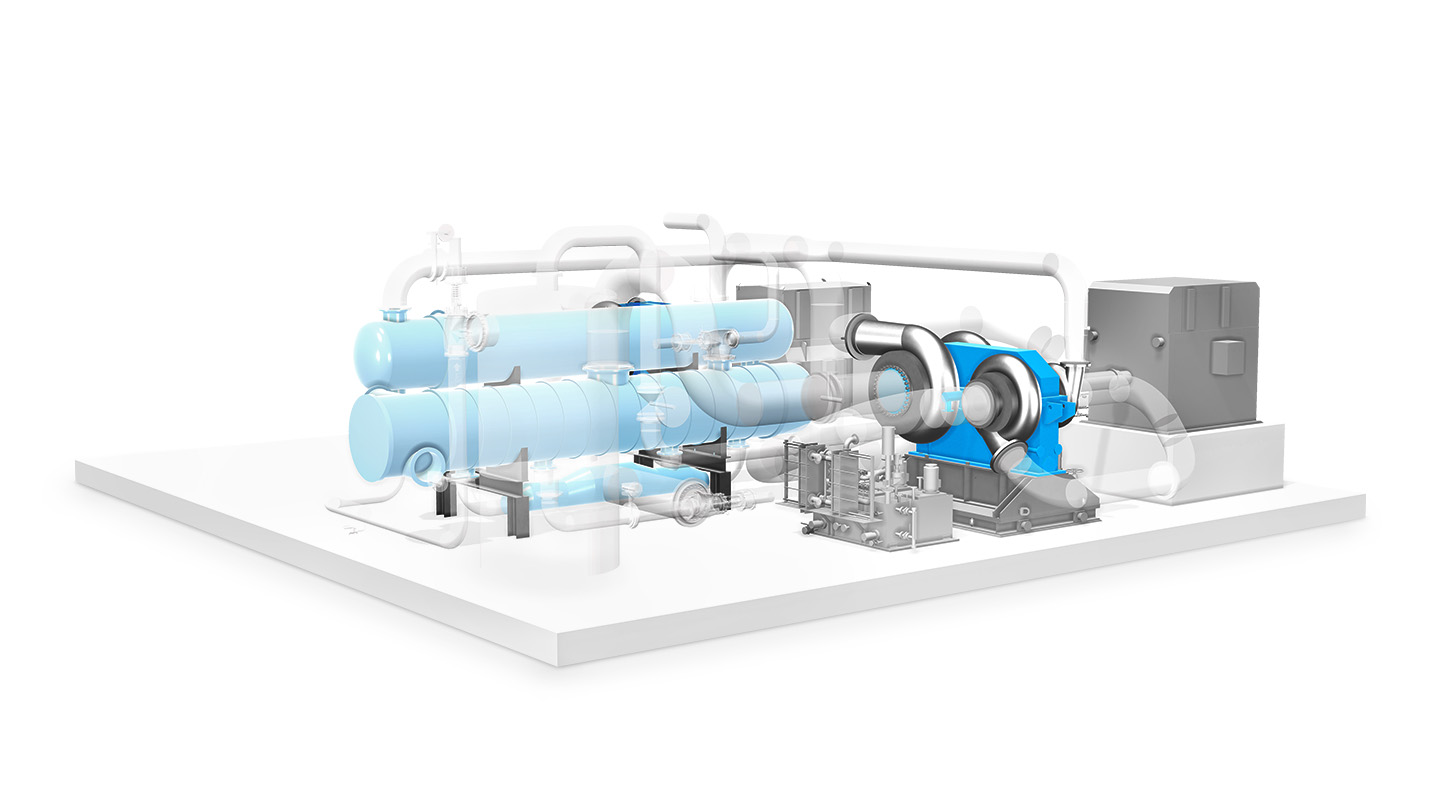

To answer your specific needs, we can offer different types of heat pump cycle based on our well-proven compressor portfolio and with careful selection of the optimal refrigerant to realize the most cost-effective and energy-efficient solution. For steam, we use the vapor compression cycle (VCC) with an additional steam compression section to achieve the precise steam condition required to produce the highest quality of paper or tissue.

Heating with vapor compression cycle (VCC) heat pumps

MAN vapor compression cycle (VCC) heat pumps are very efficient for heating and cooling processes, providing reliable steam production and hot water production up to 140 °C. The VCC heat pump system is equipped with a motor-driven radial gear type compressor. Different types of refrigerant can be used to optimize the overall efficiency.

-

Energy & Storage

Boosting energy efficiency and cutting costs in the pulp and paper industry

MAN ExpertTalk, 09:30 – 10:30(W. Europe Standard Time)We are pleased to invite you to our MAN ExpertTalk, which will focus on MAN Heat pump solutions for pulp and paper industry.

Our MAN ExpertTalk will focus on the possibilities for decarbonization as well as energy efficiency and cost savings. We will take a look at the current challenges and solutions in the market. Furthermore, our listeners will be shown how broad our solutions for the pulp and paper sector are and in which projects our energy systems and products are already being used.

-

Heat pumps

MAN Heat pumps for industrial processes

MAN ExpertTalkWe are pleased to invite you to our MAN ExpertTalk, which will focus on MAN Heat pump solutions for industrial processes.

First, we will dive into the decarbonization of industrial heat production and power-to-heat solutions for the process industry. We will look at heat and steam production and give you an overview of our vapor compression cycle heat pump technologies with insights into the latest use cases.

Your hosts will be Lothar Wallscheid and Jörg Freckmann.

-

Energy & Storage

MAN Heat pumps for industrial processes (MEA)

MAN ExpertTalkIn our MAN ExpertTalk we are examining the decarbonization of industrial heat and cold production and power-to-heat solutions for the process industry. We look at heat and steam production and give you an overview of our vapor compression cycle heat pump technologies with insights into the latest use cases. Your hosts are Ali Mushtaq and Thomas Staude.

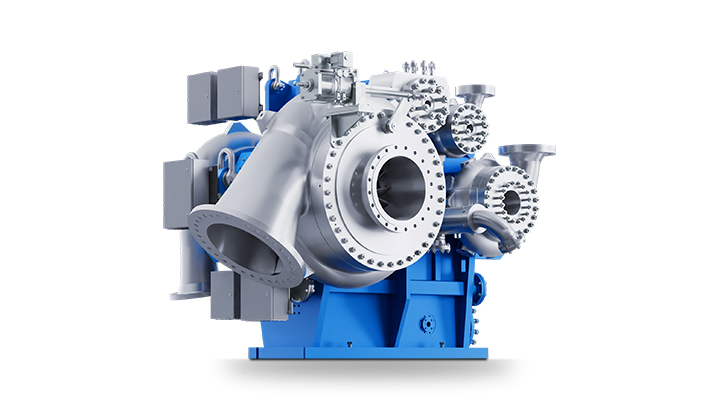

Leading compressor technology

Powerful and efficient, MAN Energy Solutions compressors are at work in industrial facilities around the world, from refineries and ammonia production plants to district heating and chemical plants. They are the core element of the heat pump drying system. Different models are available for different applications. For pulp and paper, we build and install integrally geared centrifugal compressors.

MAN RG integrally geared compressors

Lower your carbon footprint with our expert advice

Downloads

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.