The efficient way to decarbonize heating and cooling

Environmental sustainability is no longer an exclusive attribute claimed by niche food producers: the world’s largest food & beverage companies are quickly moving towards CO2-neutral production. This is made possible by the application of proven heat pump technology at industrial scale. Food & beverage companies need to produce hot and cold water, and steam, using processes that are sustainable, profitable, and competitive. Our heat pumps are a simple way to reduce your carbon footprint and your fuel costs. Their efficiency brings down the total cost of ownership and sets you free from the price and supply volatility of the fossil fuel markets – and your products will be labelled ‘carbon neutral’.

MAN heat pumps that meet your needs

In large-scale food and beverage processing, heat is commonly used for pasteurization, homogenization, fermentation, boiling, distillation, cleaning, and drying, usually at temperatures below 200 °C. We have a broad portfolio of compressor and refrigerant solutions and can customize our designs to cover your most complex needs. Our heat pump systems can be used for production of hot water and steam, and for chilling.

We can plan our large-scale industrial heat pump solutions as part of a greenfield project or to substitute for fossil fuel heat generators in an existing plant, upgrading waste heat sources and using existing infrastructure such as pipelines. Our long-standing experience ensures minimal interruption of production and long-term reliability, backed by comprehensive service.

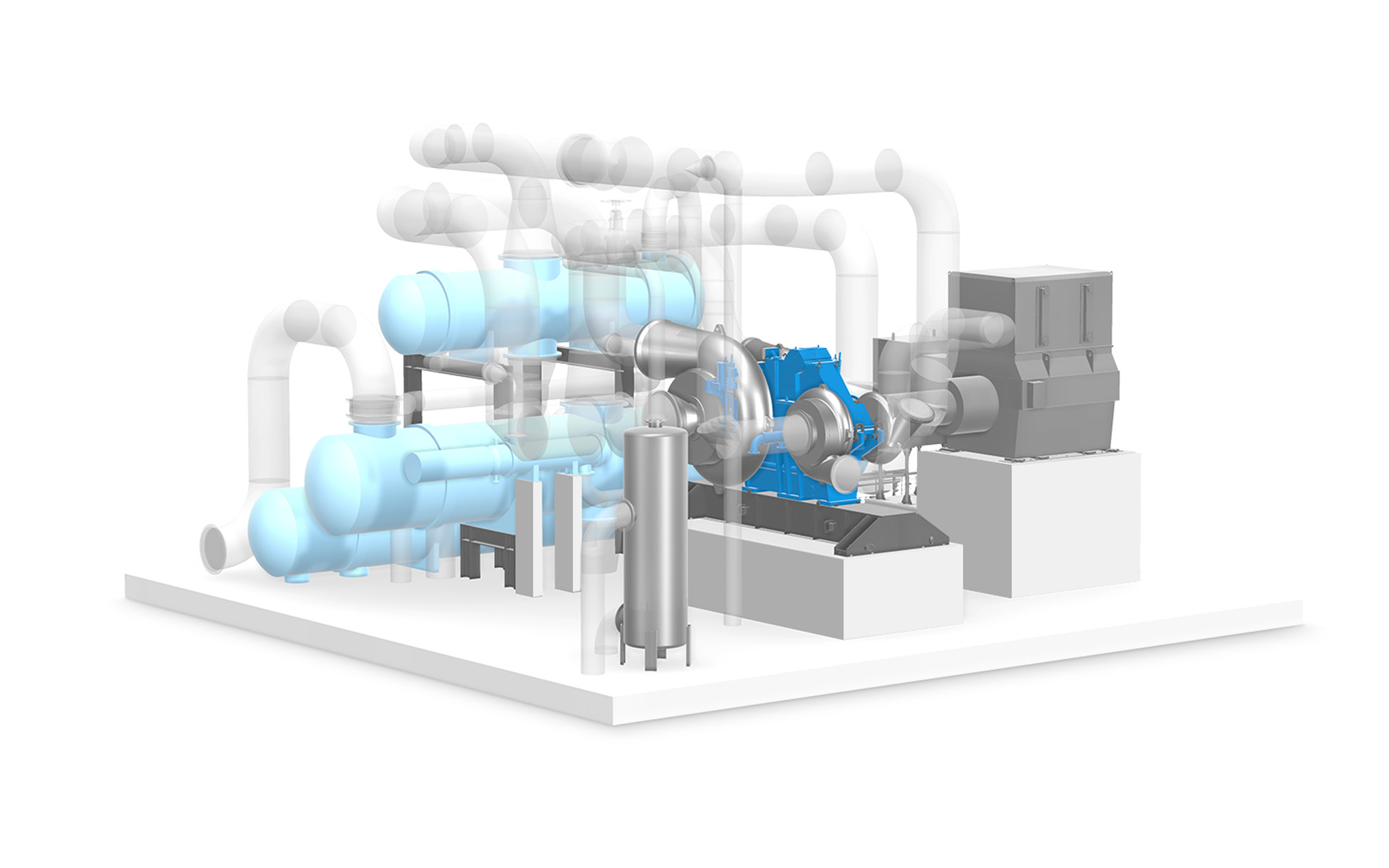

Vapor compression cycle (VCC) heat pumps

MAN vapor compression cycle (VCC) heat pumps are very efficient for heating and cooling processes, providing reliable steam production and hot water production up to 140 °C. The VCC heat pump system is equipped with a motor-driven radial gear type or inline compressor. Different types of refrigerants can be used to optimize the overall efficiency.

Expertise in complex, large-scale projects

MAN Energy Solutions has decades of experience in manufacturing and installing compressors for industrial heat pumps and refrigeration purposes. We have built thousands of integrally geared compressors, centrifugal compressors, and highspeed oil-free integrated motor compressors. They are in use in industrial facilities worldwide including ammonia production plants, the petrochemical industry, chemical plants, and district heating. Here are some examples of our industry-leading heat pump solutions for the food and beverages industry.

Steam for a vodka distillery, Sweden

MAN Energy Solutions supplied a three-stage geared compressor train for an open heat pump circuit with steam as the medium and a thermal output of over 26 MW. Steam at over 130 °C is provided on the hot side. The scope of delivery included the compressor, the process piping, the water injections, the electrical components and the control and instrumentation technology.

MAN Energy Solutions supplied a three-stage geared compressor train for an open heat pump circuit with steam as the medium and a thermal output of over 26 MW. Steam at over 130 °C is provided on the hot side. The scope of delivery included the compressor, the process piping, the water injections, the electrical components and the control and instrumentation technology.

| Compressor | RG100-3 |

| Flow | 140,400 m3/h |

| Pressure (p1/p2) | 0.40 / 2.75 bar |

| Temperature (T1) | 76 °C (max. 130 °C) |

| Power (motor) | 5,300 kWel |

Steam for a maize starch factory, Germany

Delivery of a single-stage compressor train for an open heat pump circuit with steam as the medium. Steam at over 134 °C is provided on the hot side. The scope of supply included the compressor, the process piping, the electrical components, and the control and instrumentation technology. The compressor is maintained by MAN Energy Solutions and is still running reliably after 40 years.

Delivery of a single-stage compressor train for an open heat pump circuit with steam as the medium. Steam at over 134 °C is provided on the hot side. The scope of supply included the compressor, the process piping, the electrical components, and the control and instrumentation technology. The compressor is maintained by MAN Energy Solutions and is still running reliably after 40 years.

| Compressor | GKS 530 |

| Flow | 26,820 m3/h |

| Pressure (p1/p2) | 0.40 / 2.75 bar |

| Temperature (T1) | 134 °C |

| Power (motor) | 287 kWel |

Start your decarbonization project with expert advice

Whether you're planning a large greenfield development or looking to integrate heat pumps into a complex manufacturing facility, heat pumps are an excellent way to reduce CO2 emissions, improve energy efficiency, and lower plant energy costs.

Our heat pump experts will be happy to help you put together the perfect solution for your requirements.