Reducing CO2 emissions through lower energy consumption in the paper industry

The growing global demand for packaging and tissue papers for hygiene products is fuelling a new growth in the forest-fibre and paper industry.

New opportunities in a changing market

Despite the “paperless” digital age, demand for board, tissue and pulp is on the rise. From recyclable packaging to hygiene products or pulp for clothing, many businesses rely on innovation from the paper industry. Not only must you create new products for new markets, as a business in the paper industry you will also need to find ways to reduce your environmental footprint and increase resource efficiency in a highly energy-intensive production process.

Whilst you are searching for novel wood-fibre materials and applications as well as new uses for wood and its components, you will need to update your technology to keep your business competitive. Innovative technologies from MAN Energy Solutions cut energy and water consumption in paper production lines and help you realise the next level of cost optimisation.Energy-efficient vacuum technology for perfect paper

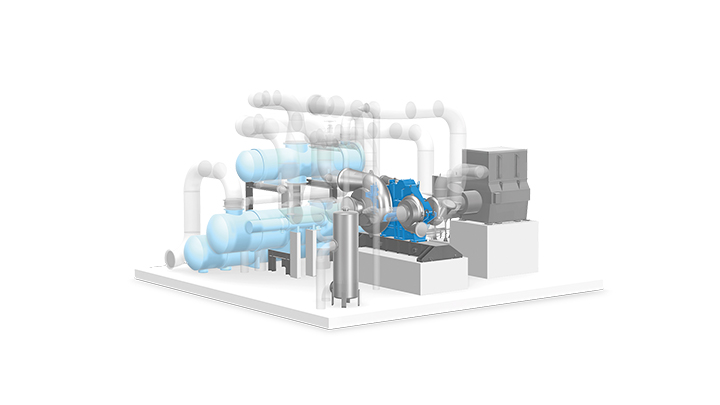

With TURBAIR®, MAN Energy Solutions offers vacuum systems developed specifically for the paper industry. Our systems dewater the paper sheet and press felts. The vacuum blowers also shift paper between sections of the paper machine and help recover water for reuse. Our TURBAIR® vacuum technology completes these tasks in a sustainable, energy-efficient, and flexible manner. TURBAIR® systems require up to 60% less energy. Additionally, it is possible to reuse the hot exhaust-air in the energy cycle using a heat exchanger, leading to a further reduction in overall energy consumption of up to 80%. Connected to a heat pump, even more savings are possible for the whole plant.

TURBAIR® vacuum blowers

TURBAIR® vacuum blowers are especially developed for paper sheet dewatering.

- Suction flow rates up to 200,000 m³/h

- Adjustable vacuum levels at various flow rates

- No water consumption

Heat pumps

Heat pumps offer the paper and pulp industry a simple way to reduce heating costs and CO2 emissions. Drying pulp, paper or tissues accounts for some 70% of the energy. With a heat range from 80 to 200 °C, MAN heat pumps can produce the steam necessary for the drying processes using waste heat streams from the drying process. Heat pumps can decarbonize the energy supply as well as reduce plant energy costs.

More on heat pumps

Decarbonizing with industrial-scale heat pumps

What is the simple alternative to producing heat with fossil fuels? Heat pumps. Find out how our heat pump solutions can make your energy more flexible and efficient, reduce carbon emissions, integrate renewables, lower costs, and much more.

MAN PrimeServ keeps your turbomachinery running

Our service engineers provide preventive maintenance, assist your troubleshooting, and get your facilities up and running in no time – wherever and whenever you need them.

How you benefit:

- Fast, reliable and expert customer support

- Bespoke service agreements

- Global service – 24 hours a day, 365 days a year

Big energy savings and optimised efficiency with two new TURBAIR® vacuum blowers

Our customer was able to achieve considerable improvements in their paper plant by replacing the existing system with two of our vacuum blowers in the production process. The successful outcome was achieved with minimal downtime.

| Customer: | Process industry |

| Year completed: | 2015 |

| Location: | Dörpen, Germany |

| Savings in electrical energy: | 44% |

| Savings in thermal energy: | 70% |

| Reduction in water use: | 10 m3/h |

| Customer benefits: |

|

| MAN’s scope of work: | 2x TURBAIR® Vacuum Blower (1x RC80-4, 1x RT56-1) |

-

Heat pumps for process industriespdf, 2130 KB

-

TURBAIR® Vacuum Systemspdf, 708 KB

-

TURBAIR® Extraction pumppdf, 720 KB

-

TURBAIR® Blower Type RCpdf, 548 KB

-

TURBAIR® Blower Type RTpdf, 539 KB

-

Steam Turbinespdf, 398 KB

-

Steam Turbines 1-180 MWpdf, 1049 KB

-

Turbomachinerypdf, 6376 KB

Contact our experts

Update your technology to give your business the edge

Could our TURBAIR® vacuum system sit at the heart of your production process, cutting costs and improving your environmental performance? Talk to us to find out more.

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.