Future proof engines for offshore wind vessels

More wind farms, bigger turbines, rougher locations: demand for renewable energy is stimulating growth in construction of wind parks at sea. Environmental logic requires we minimize the carbon footprint of installation and operation. The answer is a new class of wind farm installation vessels with clean, efficient engines that can cope with complex tasks in harsh conditions. We have drawn on our extensive experience in the offshore sector and we have future-proofed our engines for green fuels. Here you will find engines you can build on.

Wind, waves, and clean energy

The vessels that transport, install, and maintain wind turbines must live up to high environmental standards. To meet the goal of carbon neutrality, vessels need reliable engines that are clean and highly efficient: operators’ reputations depend on them. As the wind farms migrate further offshore in search of strong winds, the sea conditions become tougher.

Offshore wind engine portfolio

The methanol-ready MAN 32/44CR and MAN 175D propulsion engines and the MAN 175D GenSet are reliable, efficient, low-emission designs. These engines are perfectly suited for specialist wind farm applications such as wind turbine installation vessels (WTIVs) and wind foundation installation vessels (WFIVs) or for general offshore support vessel applications such as service operations vessels (SOV) and commissioning service operation vessels (CSOVs).

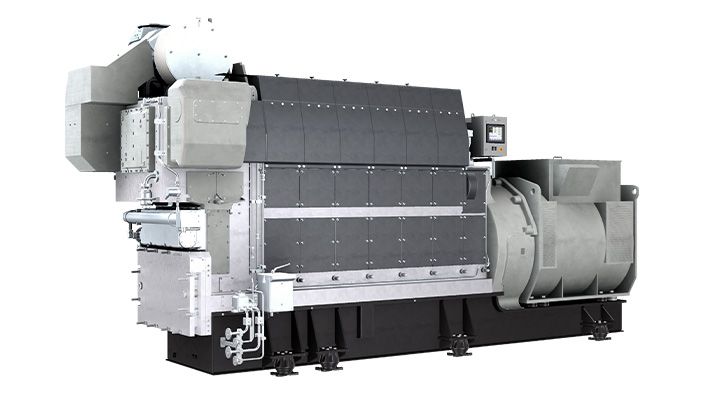

Methanol-ready MAN 32/44CR

The MAN 32/44CR brings together the most advanced large-engine technologies, including the MAN common rail system, high-efficiency turbochargers, variable valve timing and state-of-the-art control systems. These advantages are future-proofed by the availability of the methanol retrofit.

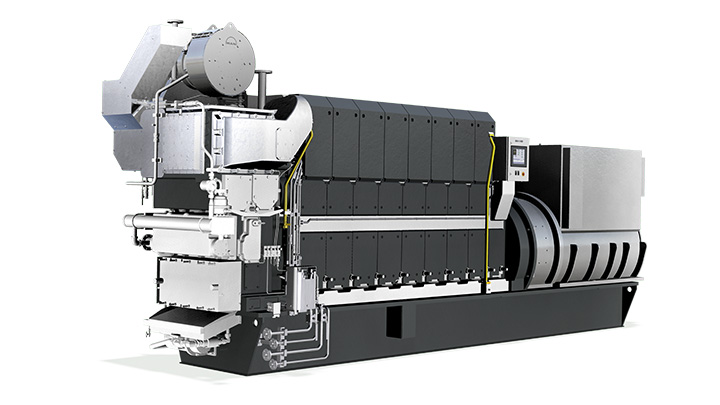

Methanol-ready MAN 175D

The most powerful high-speed engine on the market meets emissions standards without compromising on efficiency or performance. Thanks to its compact size and clear-cut design, it is easy to integrate and easy to operate and maintain. Long TBOs and low fuel consumption ensures the lowest OPEX and reduces emissions. A methanol dual fuel retrofit will be available from 2026.

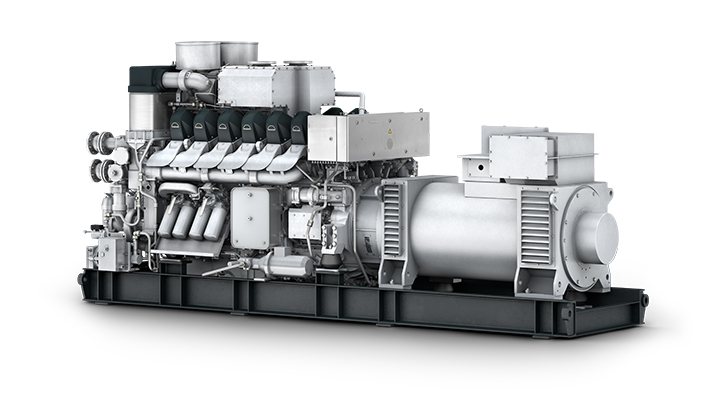

MAN 175D GenSet

Packing the latest technology into minimal space, the MAN 175D GenSet is characterized by a clear-cut design, flexible ship integration, simple operation, and straightforward maintenance. Its modular design allows it to meet all the challenges of today’s offshore applications.

MAN L21/31 Mk2

MAN L21/31 Mk2 offers reliable power,

stable operation and the possibility to operate this engine on conventional

fuels as well as biofuel oils. Optimized engine design with improved fuel

efficiency delivers cost efficiency during its entire life cycle. This engine

represents a safe investment for your offshore wind vessel.

Methanol-fuelled MAN L21/31DF-M

Methanol-fuelled MAN L21/31DF-M is a compact and reliable engine which offers fuel flexibility and possibility to lower greenhouse gas emissions. It can be operated on methanol, conventional fuels as well as most biofuel oils. With its outstanding load-step capabilities and extremely long time between overhauls (TBOs), it is a perfect future-proof solution suitable for powering your offshore wind vessel.

MAN L27/38 Mk2

Powerful MAN L27/38 Mk2 delivers improved competitiveness and reliable operation which make it a solution suitable for most offshore applications. This engine can run on conventional fuel types as well as biofuel oils and offers cost efficiency during its entire life span. The methanol version of this engine (MAN L27/38DF-M) is already in development.

MAN ExpertTalks

-

Energy & Storage

From source to solution: Methanol’s missing link in energy transition

MAN ExpertTalkE-methanol is produced using renewable energy. This often comes from offshore wind turbines, which are installed by specialized vessels, which are powered by MAN methanol engines. These are just some of the links in the methanol value chain, but they show how MAN Energy Solutions can bring together suppliers and consumers of methanol. We also provide links through CCS, hydrogen electrolysis, and methanol synthesis.

References

Multiple MAN Engines Ordered for New Generation of Offshore Installation Vessel

China Merchant Heavy Industry (CMHI) has ordered 6 × MAN 12V32/44CR main engines in connection with the building of a new 5,000-tonne floating installation crane vessel – already christened ‘Les Alizés’ – for Jan De Nul Group, an international maritime construction expert.

Delivering a cumulative output of 43,200 kW, the common-rail engines will each feature an enhanced, MAN-supplied SCR (Selective Catalytic Reduction) system for IMO Tier III-compliance, and will also meet the even-stricter Euro Stage V-compliant NOx-emission limit. The enhanced NOx-reduction rate is essential for the newbuilding to fulfill the exacting ULEV (Ultra Low Emission vessel) standard for better air quality, characterised by very low NOx and particle emissions.

Les Alizés will be built at CMHI’s shipyard in Jiangsu province, eastern China, and is scheduled for delivery in 2022.

Lex Nijsen, Head of Four-Stroke Marine Sales – MAN Energy Solutions, said: “The MAN 32/44CR’s robust design is proven across many applications and I’m very happy to see it chosen again for such an exciting project. MAN Energy Solutions has previously worked with Jan De Nul Group on many of its vessels and recently provided four 12V32/44CR engines to CMHI for a major semi-submersible project. We look forward to working with our partners again in the commissioning of such a noteworthy vessel that truly begins a new era for the offshore installation sector.”

Jan De Nul Group is a world leader in dredging and offshore technology and operates a modern and versatile fleet of dredging and offshore-installation vessels that currently features over 90 MAN engines.

Unique features

MAN Energy Solutions states that several of the 32/44CR’s unique features were important in it being choosen for the project.

Accordingly, the engines will be delivered with the company’s innovative ECOMAP feature. The CR-system’s flexibility permits the engine to be programmed to run along different fuel-consumption-versus-power characteristics, with each having its efficiency optimum at a different load point.

Another key 32/44CR characteristic is that high engine-output is available even at high ambient temperatures, as well as at the high exhaust-gas back-pressures resulting from the extensive exhaust-gas treatment equipment, which is mandatory for the ULEv notation.

New generation

Les Alizés’ genesis stems from the global trend within the offshore wind-energy segment for increasingly larger wind turbines. These can be more than 270 metres high – with blades up to 120 metres long – and can be mounted on foundations weighing up to 2,500 tonnes: dimensions that current offshore installation vessels have trouble installing.

Les Alizés will be in a super-size class of its own, capable of building the next generation of offshore wind farms but whose crane – with a lifting capacity of 5,000 tonnes and equally impressive lifting heights – also renders her capable of decommissioning offshore oil and gas platforms.

About Jan De Nul Group

Design. Build. Connect. Jan De Nul Group shapes water and land. Worldwide. From complex offshore services for oil and gas and renewables, to large dredging and both land and coastal reclamation projects, to challenging civil construction programmes. Well integrated competences and investments lead to creative, sustainable and innovative solutions. In this way Jan De Nul Group delivers results that produce satisfied customers. Building a better future. – www.jandenul.com

Documents

-

20200430_MAN_ES_PR Jan de Nul 5000t Crane Vessel_EN

-

20200430_MAN_ES_PR Jan de Nul 5000t Crane Vessel_DE

-

20200430_MAN_ES_PR Jan de Nul 5000t Crane Vessel_CN

Contact

Nils Søholt

Trade Press Marine

Group Communications & MarktingMAN Energy SolutionsTeglholmsgade 412450 Copenhagen SVDenmark

nils.soeholt@man-es.com t +45 33 85 26 69Get notified about press releases

Find out how we can help you

Get in touch with our offshore vessel experts and discover how we can create an efficient and future-proof solution for your wind farm installation vessels.