Inside the Research Centre Copenhagen of MAN Energy Solutions

As major companies like Amazon and Ikea push for carbon neutral supply chains, the men and women at the Research Centre Copenhagen (RCC) are making it happen, developing crucial solutions for shipping to go greener. They’ve already developed innovative dual-fuel two-stroke engines that can run on LNG, LPG, ethane and methanol – ammonia is next.

By Niels Anner

“The engine control room is like the bridge of a ship,” says Holte Nielsen as he holds the control handle and looks at the monitors in front of him, checking the measurements of the massive engine. Is it me, or is the room vibrating slightly? The view through the large windows doesn’t give out to the open sea – or even a cargo deck, for that matter. Instead, we’re looking out onto a spacious white hall filled up with green pipes and black cables and a ten-meter-high engine – all part of the MAN Energy Solutions’ innovative Research Centre Copenhagen (RCC) in Denmark, where Casper Holte Nielsen works as a research engineer on full-scale engine tests of future fuels.

The view from the engine control room: The RCC Research Engineer Casper Holte Nielsen reviews the latest consumption, emissions and heat load measurements for the ME-GA engine. ©Niels Busch

Located near the Copenhagen Harbor, the RCC researches, designs, develops and tests the latest technologies and components for the next generation of environment-friendly two-stroke engines. In fact, the engine being put through its paces now, an ME-GA, is one of two research engines being used here to support the decarbonization of the shipping industry. Oh, and yes, the room is vibrating.

Adapted for carbon-free fuels

“Our research engines are based on highly adaptable combustion engines,” explains Holte Nielsen, 34, who had already worked at MAN Energy Solutions during his studies as a mechanical engineer. “Then they’re adapted several times” – previously, for liquefied natural gas (LNG), liquefied petroleum gas (LPG), ethane, methanol and very soon for carbon-free ammonia. The work being done here is essential for the maritime energy transition, piloting prototypes that will run on synthetic fuels – the clean fuels of the future – before the designs are scaled up to propel some of the largest ships in the world.

Over the last decade, the RCC has already been crucial for important milestones on the way to lowering the shipping industry's carbon footprint. For example, in 2011, they introduced the dual fuel two-stroke engine ME-GI – an engine capable of running on both gas and/or diesel to reduce greenhouse emissions. Just this October the ME-GI reached two million hours operating worldwide on LNG alone, which generates around 24 percent less carbon emissions than conventional fuel oil engines.

Further milestones are in sight. Maersk, the largest container shipping company, has plans to put the world’s first carbon-neutral feeder vessel into water in 2023, powered, of course, by green methanol on a G50ME-C-LGIM engine that was perfected at the RCC. And in 2024, Maersk will introduce the first of eight large carbon-neutral container ships operating with a G95ME-C-LGIM engine. In the same year, MAN aims to present a two-stroke ammonia engine, followed by a retrofit package for existing maritime vessels in 2025.

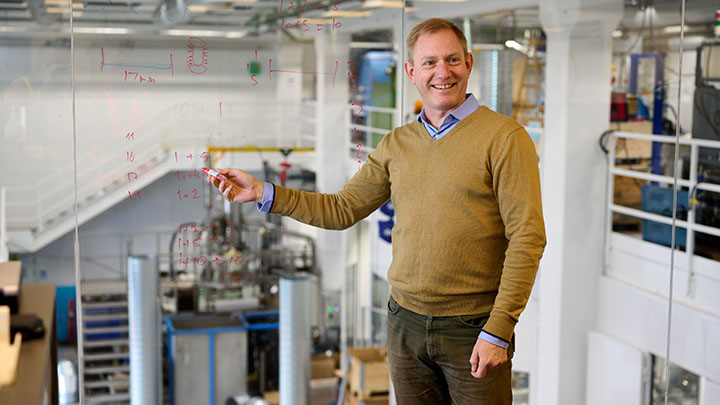

The work being done at the Research Centre Copenhagen to decarbonize the shipping industry “is all about innovation and technical advancements,” says Holte Nielsen. ©Niels Busch

We often do things here that have never been tried before – it’s all about innovation and technical advancements.

Building on what works: The innovations for the next generation of methanol and ammonia dual-fuel engines at the RCC are based on established technology, says Research Engineer Mikkel Kjul Ankerbye. ©Niels Busch

The evolution of carbon-free two-stroke engines

Research Engineer Mikkel Kjul Ankerbye, 49, explains in a nutshell how the evolution of environment-friendly two-stroke engines works: “So, we first transferred our established gas injection technology to work with ethane, methanol and LPG. Then this, in turn, becomes the new basis for the next generation of larger methanol and ammonia engines.”

The design has been tested, verified and validated over the years, says Kjul Ankerbye, who has 20 years of experience in various R&D and design functions at MAN Energy Solutions. “Now it’s being optimized for ammonia.” While using new fuels means that critical parts such as injectors, exhaust valves and even control systems will have to be modified, the aim is to find a design that only needs a few adjustments and add-ons.

Components are developed in two stages at the RCC. Before being installed on one of two four-cylinder research engines, the design is tested at the test rigs (frequently only a one-cylinder setup) and, if necessary, further developed and optimized. Often the components are tested to the limits. “This way we can prevent damaging our engine,” Kjul Ankerbye explains. To validate the functionality, measurements are crucial – no matter whether components for research or production engines are concerned. Hundreds of measuring points need to be placed in order to get the right data.

“Time and again we’re breaking new ground,” says Holte Nielsen, “We often do things here that have never been tried before – it’s all about innovation and technical advancements.” He gives an example that when testing, initially only one cylinder will run on, say, gas, while the other three run on diesel. “This way we can experiment with one of them and the other three control the stroke.”

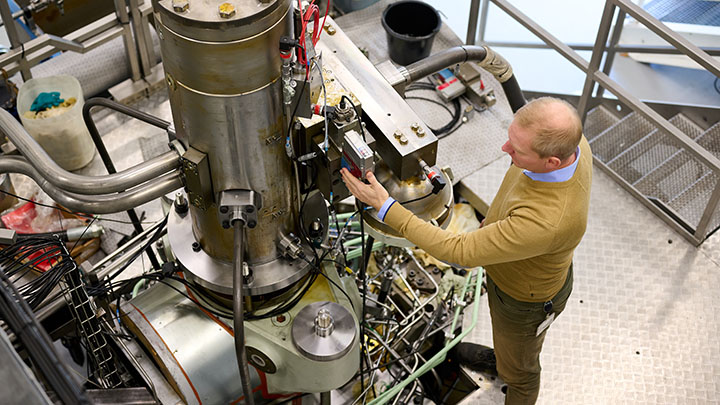

Kjul Ankerbye handles the research rig TM95ME-C10.6, which supports the testing of top-controlled exhaust valve (TCEV) and sequential operated fuel booster injection valve (FBIV) technology. ©Niels Busch

“Turn the supertanker around”

Holte Nielsen and the rest of the engine team work closely with designers and engineers who specialize in software and performance, continually improving the test setup and further developing engines and control systems. And all the engineers at the RCC are motivated by contributing to the decarbonization of the shipping industry.

“We’re doing our part to turn the supertanker around and halt climate change”, says Kjul Ankerbye. But other players are needed, too. The engines alone won’t be able to reach net-zero without a supply and infrastructure for green fuels. MAN Energy Solutions is therefore one of the founding members of the Center for Zero Carbon Shipping, a non-profit research and development center that wants to speed up the maritime energy transition.

“There’s no doubt, we have ambitious goals and a tight timetable,” says Katerina Tsalapatis, who works at the RCC in project management and research support. A biological anthropologist by training, Tsalapatis has worked at MAN Energy Solutions for almost 20 years, cowriting technical R&D papers and presentations and monitoring audits. "It’s typical for the RCC to be passionate about advancement,” she says, “from the drawing board to the hands-on testing of individual parts and finally the entire engine of a huge container ship.”

We’re doing our part to turn the supertanker around and halt climate change.

RCC Project Assistant Katerina Tsalapatis on accelerating the maritime energy transition with e-Fuel capable engines: “We have ambitious goals and a tight timetable.” ©Niels Busch

It remains to be seen which green fuels the market will eventually favor. “Developing engines with flexible – and intensively tested fuel options,” says Tsalapatis, “is a great solution for newbuilds and retrofits.” New orders from big shipping companies are proving Tsalapatis right, and the industry is receiving increased pressure from its customers to decarbonize. Most recently, various multinational companies such as Amazon and Ikea joined the Cargo Owners for Zero Emission Vessels initiative, demanding zero-carbon shipping by 2040.

“The industry is waiting for green fuel solutions,” says Holte Nielsen, “and we’re proud to be doing our part with new technologies.”

Developing engines with flexible – and intensively tested fuel options is a great solution for newbuilds and retrofits.

About the author

Niels Anner is an independent journalist based in Copenhagen, who writes on business, science, technology and society in Northern Europe.

Explore more topics

-

Hoegh - LNG-powered car carrier

With its first LNG-powered car carrier, Höegh Autoliners is taking a big step towards its target of net-zero by 2040. The centerpiece of the vessel is a MAN Energy Solutions MAN B&W ME-GI dual-fuel engine.

-

Maersk Halifax Retrofit

The world’s first methanol retrofit of the Very Large Container Vessel Maersk Halifax opens the doors for green fuels.

-

Methanol dual fuel retrofit

Engineers are now testing a retrofit for four-stroke ship engines that will enable ferry and cruise ship operators to meet the growing requirements on emission reduction with green methanol.

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.