A solar mini-refinery captures carbon and solar power to create a CO2-neutral alternative to fossil fuel.

There is no single cure-all to climate change. Instead a number of innovative technologies will be needed to make our industries, power generation and mobility less dependent on fossil fuels. MAN Energy Solutions monitors the latest advances bringing us closer to a sustainable future. One elegant development is currently underway on a Swiss rooftop, where ETH Zurich and the spin-off company Synhelion produce carbon-neutral fuel from nothing but sun and air.

by Santina Russo

Capturing sunlight in a bottle

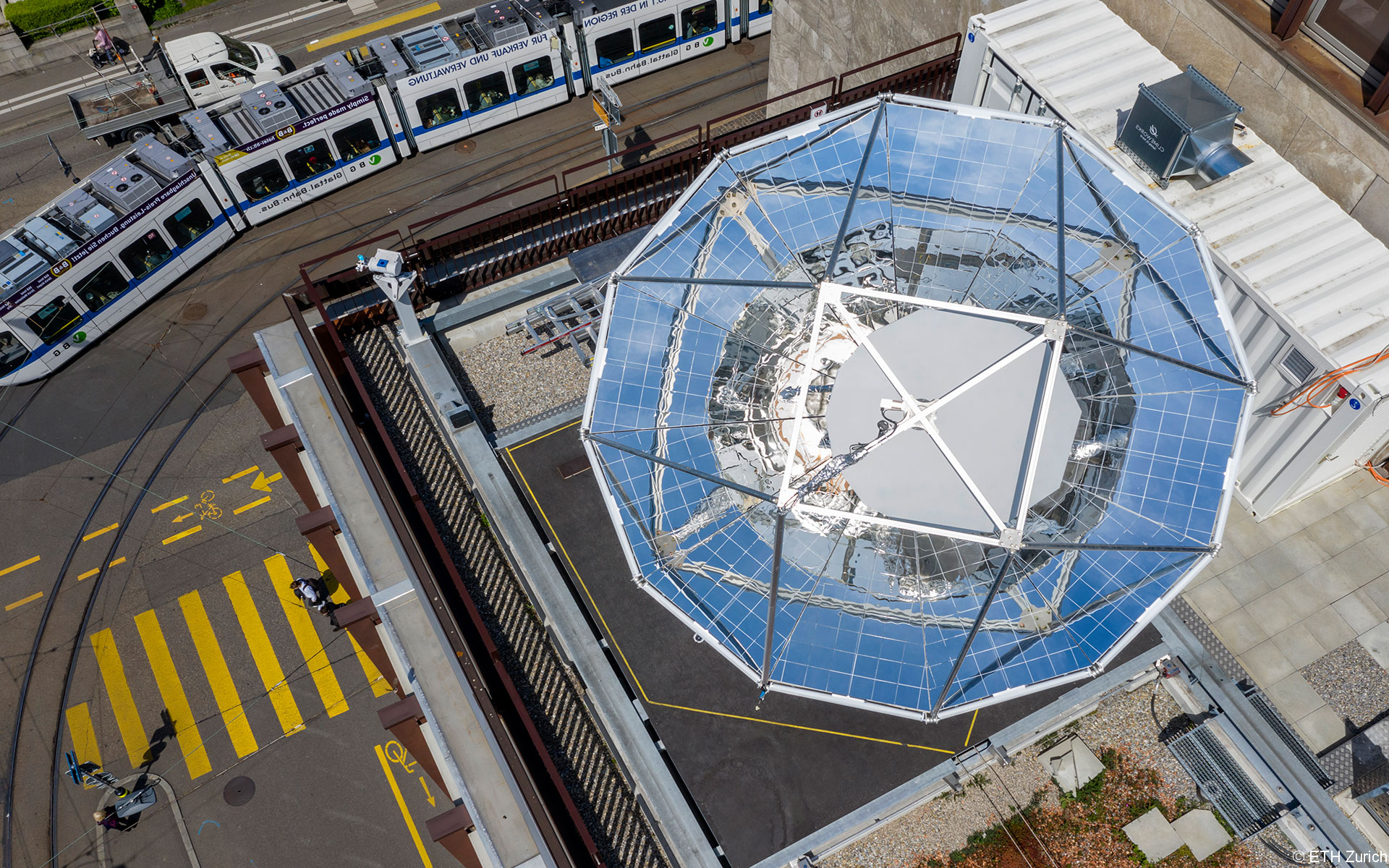

At first glance it looks like a gigantic parabolic antenna. But then Remo Schäppi points out the mirrors covering the nearly five-meter-wide surface, as well as the smaller mirror mounted above. “The parabolic mirror directs the sunlight on the secondary mirror, which in turn can be adjusted to transfer the energy into the reactor vessels,” explains Schäppi. He is a PhD student in the Professorship of Renewable Energy Carriers at ETH Zurich and in charge of the machine sunbathing high up on the roof of the ETH building. This solar mini-refinery is accomplishing a task as radical as it is impressively straightforward: It creates fuel using only ambient air and sunlight.

As yet the process is in prototype scale, yielding some 100 milliliters of fuel per day. But the ETH-spin-off Synhelion wants to take it to industry level fast, says Philipp Furler, the company’s CTO. He is convinced that the technology can go a long way towards meeting international climate goals. “It has become clear that new technologies are needed to fuel ground and air traffic without the consumption of fossil materials.” Several solutions like electric cars or power units driven by biogas or hydrogen are already in place or in development for road transport, but conventional liquid fuels for long-haul heavy transportation by land, sea or air remain indispensable – and therefore so are the technologies producing them from renewable sources.

The solar mini-refinery yields syngas, which can be turned into some 100 milliliters of CO2-neutral fuel per day – methanol, petrol, diesel or kerosene.

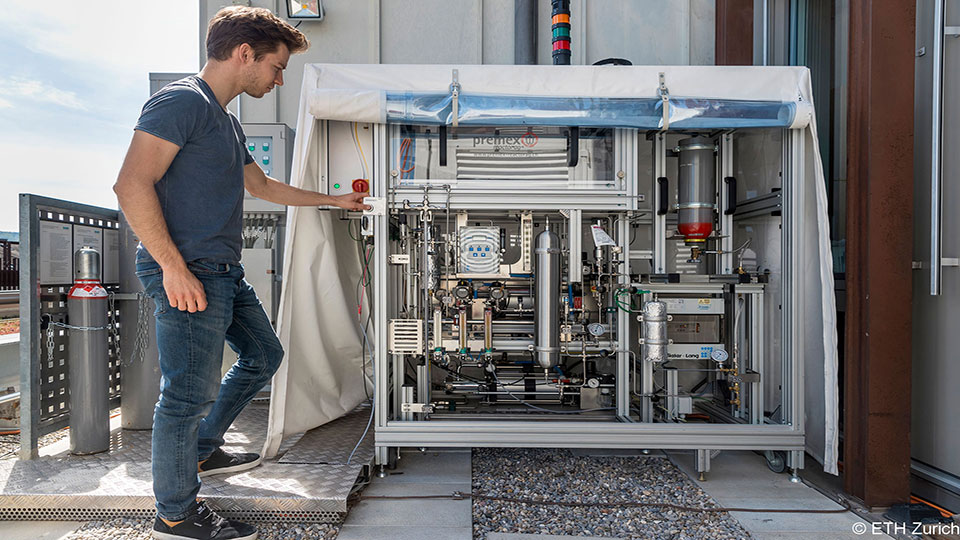

The syngas is compressed to up to 200 bar for the following liquefaction into fuel.

A bright idea: inside the solar reactor

Back on the roof of the ETH, the scientist Remo Schäppi puts on his large protective sunglasses, then pushes a button on the computer controls, and the square mirror moves – one second, two seconds, until a bright light point appears on one of the two reactor vessels mounted in the middle of the parabolic structure: 3000-fold concentrated sunlight. The focused solar energy will now heat-up the reactor to 1500 degrees Celsius.

Inside the reactor vessels, water and carbon dioxide (CO2) are transformed into hydrogen (H2) and carbon monoxide (CO) – a mixture called syngas. This is visible from the outside, or rather, the heat in the reactor vessel is: In fact, after a few more minutes, the irradiated container starts to glow bright orange.

Closing the carbon circle

The syngas created here serves as precursor for the production of various fuels – methanol, petrol, diesel or kerosene. And those resulting fuels are CO2-neutral since both the water and CO2 used in the reaction are previously being extracted from ambient air, in a process developed at ETH Zurich as well.

This manner of fuel production has big potential for high energy conversion efficiency, says CTO Philipp Furler. “Our technology employs a more direct approach than electrochemical or biofuel methods using solar energy to produce fuel”. However, as any solar driven technology it is dependent on the availability of sunlight. “In Zurich we get around 1200 kilowatt hours per year per square meter of solar irradiation, whereas in desert areas that can go up to 3500 kilowatt hours per year,” Furler points out. This translates to a 3-fold increase of production. The Synhelion-System will be therefore best placed in desert areas. “Theoretically,” says Furler, “a plant the size of a third of the Californian Mojave Desert – could cover the kerosene needs of the entire aviation industry.”

The prototype atop the ETH Zurich is small, but the system can be expanded, and Synhelion aims to have a reactor developed to industry standards by 2025.

Combining future fuels for the energy transition

“We are convinced that synthetic fuels will drive the future and are key to a decarbonized world,” says Marc Grünewald, who is one of the driving forces of new energy solutions at MAN Energy Solutions and is constantly looking for promising technologies. “The Sun-to-Liquid concept sounds like a promising project, as it can turn sunlight directly into synthetic gas without intermediate steps. However, there are still some challenges to be solved. In the current setting, the required space seems quite high if you aim to produce syngas at an industrial scale. But if Philipp Furler and his team succeed in further increasing the efficiency while reducing the required space, Sun-to-Liquid could turn itself from a promising research project into a serious alternative on the road to decarbonization.”

Grünewald and his team at MAN are working hard to find the best solutions for a sustainable energy supply. For example, the Power-to-X technology, which can convert renewable energy from wind or solar power plants into carbon-neutral fuels, is perfect for the interplay with electrical infrastructure and already available at an industrial scale. In 2013 MAN supplied a methanation unit for a Power-to-Gas reactor for a German Audi plant, producing synthetic natural gas that can be fed into the existing gas grid infrastructure to supply Audi customers’ gas-powered cars. And the company has a 50-megawatt Power-to-X solution on offer. “The future,” reckons Furler, “will bring not just one winning technology, but a mixture of several, that can be applied depending on environmental conditions.”

10 million liters of methanol per year

Furler is also working hard on the next version of the solar fuel system which will be considerably larger, utilizing more than 300 kilowatts of solar radiative power for fuel production – 60 times more than the reactor at ETH. Furler and his colleagues are currently testing components for this succession model in Germany. Already in 2025 the company plans to be ready with a system developed fully for industrial standard. This model will then be designed for a production volume of 10 million liters of methanol per year.

Meanwhile in Zurich, a few clouds are starting to hide the sun and it is getting late. Remo Schäppi takes off his protective glasses. Time to park the solar reactor in its garage and hope for a sunny day tomorrow.

Theoretically, a plant the size of a third of the Californian Mojave Desert – could cover the kerosene needs of the entire aviation industry.

About the author

Santina Russo is a freelance journalist in Zurich, Switzerland, for various media and organizations in the field of knowledge and technology.

Explore more topics

MAN Energy Solutions is now Everllence.

We have adopted a new brand name and moved to a new domain: www.everllence.com. This page will also be relocated there shortly. We are working on shifting all pages to www.everllence.com.