Leading the way in sustainable two-stroke propulsion

MAN B&W two-stroke engines offer unrivaled fuel flexibility and thus future-proof propulsion. Our two-stroke engines are already now capable to operate on a broad variety of alternative fuels – from methanol, to methane and ammonia.

By placing your trust in a reliable partner, you can benefit from reliable and proven technology – today and in the future.

Let’s navigate the future of shipping together.

High power combined with high efficiency:

Discover our portfolio of proven MAN B&W two-stroke engines

MAN B&W ME-C

Our ME-C engines with

electronic controls serve up a host of advantages. You can look forward to

superior performance parameters, compactness, fully integrated electronic control

as well as the necessary fuel injection pressure and rate shaping at any load.

Plus the ME-C engine can be retrofitted for alternative fuels such as methanol,

LPG, LNG or ethane as well as ammonia from 2025.

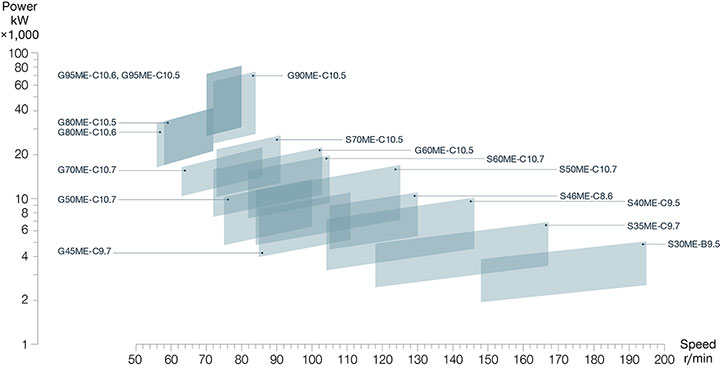

- Engine speed: rpm to 56 – 167

- Output: 4,350 – 82,440 kW at L1

MAN B&W ME-GI

The ME-GI engine impresses with extremely low methane slip emissions and very high fuel efficiency. It is the most environmentally friendly LNG-fuelled engine on the market. By the optional use of fuel oil or LNG/bio-methane/SNG, it represents a highly efficient, flexible, propulsion-plant solution.

- Engine speed: rpm to 56 – 167

- Output: 4,350 – 82,440 kW at L1

MAN B&W ME-GIE

The technology of the ME-GIE is based on our successful ME-GI engine. This engine can be operated with ethane as well as fuel oil – which makes it the standard choice for ethane carriers. This engine offers very competitive fuel oil and gas consumption, plus operational stability and efficiency due to the diesel principle.

- Engine speed: 62 – 127 rpm

- Output: 8,600 – 29,120 kW at L1

MAN B&W ME-GA

The ME-GA engine is the latest addition to our dual fuel portfolio. Gas is admitted during the compression stroke, which allows for a lower supply pressure compared to other dual fuel engines. This is advantageous for LNG carriers with large amounts of boil-off gas. The ME-GA engine comes with our proven EGR design as standard for reduced methane slip emission, as well as improved fuel efficiency in both gas and fuel oil mode.

- Engine speed: rpm to 66 – 78

- Output: 14,150 – 16,980 kW at L1

MAN B&W ME-LGIM

Our ME-LGIM is a dual-fuel engine characterized by its high efficiency and capability of operating on methanol. With a proven record of more than 600.000 operating hours on methanol alone, the engine concept is proven and provides a high degree of reliability.

When fuelled by green methanol, our ME-LGIM engine can offer truly carbon-neutral propulsion, while reducing sulphur and particle matter emissions significantly at the same time.

- Engine speed: 58 – 117 rpm

- Output: 6,950 – 82,440 kW at L1

MAN B&W ME-LGIP

Our ME-LGIP is the only two-stroke dual-fuel engine on the market which can be fuelled with LPG. The low operational costs as well as the simple retrofit solution are particularly convincing.

- Engine speed: 62 –105 rpm

- Output: 8,600 – 22,720 kW at L1

Always an optimal choice

The MAN Energy Solutions two-stroke portfolio delivers the highest performance and efficiency across all engine types.

MAN B&W two-stroke engines from the 30 to 95 cm bore sizes have a total power range from 3,200 kW to 82,440 measured at L1. With a vast range of different fuel injection concepts from traditional fuel oils, to gaseous and liquid gasses, MAN ensures that you have your future fuel strategy covered.

All MAN B&W engines follow the same naming convention and seemingly random engine names actually carry a lot of useful information.

Explore our interactive marine propulsion systems

Worldwide service solutions

Dedicated to developing solutions

Are you are wondering what role our two-stroke technologies could play in your future? We are happy to answer your questions.

Useful tools

Continue reading

-

MAN L27/38DF-Mpdf, 386 KB

-

Marine engine programme 2024pdf, 18117 KB

-

The Methanol-fuelled MAN B&W LGIM enginepdf, 9427 KB

-

MAN B&W ME-LGIMpdf, 508 KB

-

Economiser energy control for increased service steam production.pdf, 3390 KB

-

Power into the future B&W ME-LGIP:pdf, 1511 KB

-

MAN B&W ME-GApdf, 2419 KB

-

Efficiency improvements Main engine auxiliary systemspdf, 4409 KB

Related products

-

Four-stroke small-bore engines

With our small-bore engines, you are prepared for whatever lies ahead.

-

-

MAN B&W ME-LGIM

The MAN B&W ME-LGIM is a two-stroke, dual fuel engine that runs on both methanol and conventional fuels.

Related news

COSCO Signs Up for Methanol Retrofits

COSCO Heavy Industry Shanghai Co. Ltd. has signed a contract with MAN Energy Solutions for the methanol retrofit of four main engines from COSCO Line’s ‘Camellia’ and ‘Virgo’ -class vessels – 13,800 and 20,000 teu respectively. Currently equipped with single-fuel MAN B&W 11S90ME-C10.5 engines, the vessels will be retrofitted to dual-fuel MAN B&W 11S90ME-LGIM10.5 units capable of operating on fuel-oil or methanol, in the process becoming the first vessels in COSCO’s fleet to sail on methanol.

The contract also includes an option for the retrofit of an additional nine vessels from the line’s 20,000 teu ‘Virgo’ and ‘Pisces’ -classes. COSCO Heavy Industry Shanghai Co. Ltd. will act as complete turnkey solution provider for the COSCO Line retrofits.

MAN Energy Solutions will provide a solution package comprising engineering, parts, project management, onsite technical assistance at yard, sea-trial assistance and recertification service for the engine retrofits. To this end, the company has undertaken an R&D programme and invested in a testbed to develop the S90-LGIM (Liquid Gas Injection Methanol) retrofit solution. The first vessel of the series is scheduled for retrofit in Q2 2025 when these vessels will also become the first fitted with S90-LGIM engines to sail the world’s oceans.

Michael Petersen, Senior Vice President and Head of PrimeServ Denmark, said: “It’s very promising to see one of the largest shipping companies globally choosing MAN Energy Solutions as a partner to attain their decarbonisation goals. We are committed to bringing more retrofit solutions to the market and our investment in the S90-LGIM R&D and testbed programme is a fulfilment of this promise to our customers.”

The new order follows on the heels of the recent methanol retrofit order by A.P. Moller – Maersk, the Danish integrated logistics company – for the retrofit of the G95 main engines aboard 11 of its container vessels to dual-fuel. More than 300 vessels globally are currently equipped with S90 engines and MAN Energy Solutions expects this new business to kick off a major wave of S90 retrofits.

Petersen continued: “Our retrofit solutions are now accepted as a proven way of attaining dual-fuel capability to deliver lower emissions, and COSCO’s methanol retrofits are yet another instance of this. We are in the early days of a huge wave of dual-fuel retrofits and see many concrete projects coming online with the capacity to meet shipping’s demand for green fuels, such as e-methanol and bioLNG. We expect that owners who have opted to wait and watch over the past few years will ultimately also convert their tonnage to dual-fuel.”

Sarath Prasannan, Head of Region APAC, said: “2030 is the year where China targets peak carbon-emission, while 2060 is its target for achieving net-zero. The decision to retrofit the propulsion engines in its fleet to methanol operation is a bold step in the right direction from COSCO, leading the way to green transportation and maritime decarbonisation. MAN Energy Solutions will stand with COSCO all the way to ensure a smooth execution of this dual-fuel engine conversion project, strongly supported by our team in China. Furthermore, PrimeServ China is currently gearing up its market presence so as to be capable of servicing large retrofit projects at multiple yards simultaneously.”

About MAN PrimeServ’s LGIM retrofit solution

MAN Energy Solutions’ experts continually develop class-leading technologies that facilitate shipping’s journey to net-zero, keeping in mind owners’ and operators’ environmental and commercial goals, as well as today’s and tomorrow’s regulatory standards.

Retrofitting an engine to dual-fuel operation is one of the most effective ways to drive greater efficiency and profitability from a fleet. A dual-fuel conversion gives the fuel flexibility to take advantage of optimal fuel prices, while making vessels compliant with IMO and local emission-control measures and legislation such as FuelEU – all leading to a greater return on investment.

The -LGIM retrofit solution, developed based on experience gained from -LGIM engines aboard methanol carriers operating at sea for multiple years, enables existing single-fuel vessels to operate as dual-fuel vessels. This fuel-flexibility, with the option of running on methanol, brings such benefits as lower CO2, particulate matter and SOx emissions.

(Second picture: ‘COSCO Shipping Virgo’, a Virgo-class vessel in the COSCO Line fleet (courtesy COSCO Line))

Pictured at the signing at Marintec Shanghai: (front left) Xiaodong Guo, Managing Director of COSCO Heavy Industry Shanghai CO.,Ltd. and (front right) Michael Petersen, Senior Vice President and Head of PrimeServ Denmark

Documents

-

PR COSCO Methanol Retrofits_EN

Contact

Nils Søholt

Trade Press Marine

Group Communications & MarktingMAN Energy SolutionsTeglholmsgade 412450 Copenhagen SVDenmark

nils.soeholt@man-es.com t +45 33 85 26 69Available languages

- DE ·

- EN